Temperature-adjustable four-effect drying system

一种干燥系统、调温的技术,应用在污泥干燥、热回收系统、干燥气体布置等方向,能够解决干燥周期长、除湿量小、占地面积大等问题,达到减小主体结构体积、维修空间小、占地面积小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

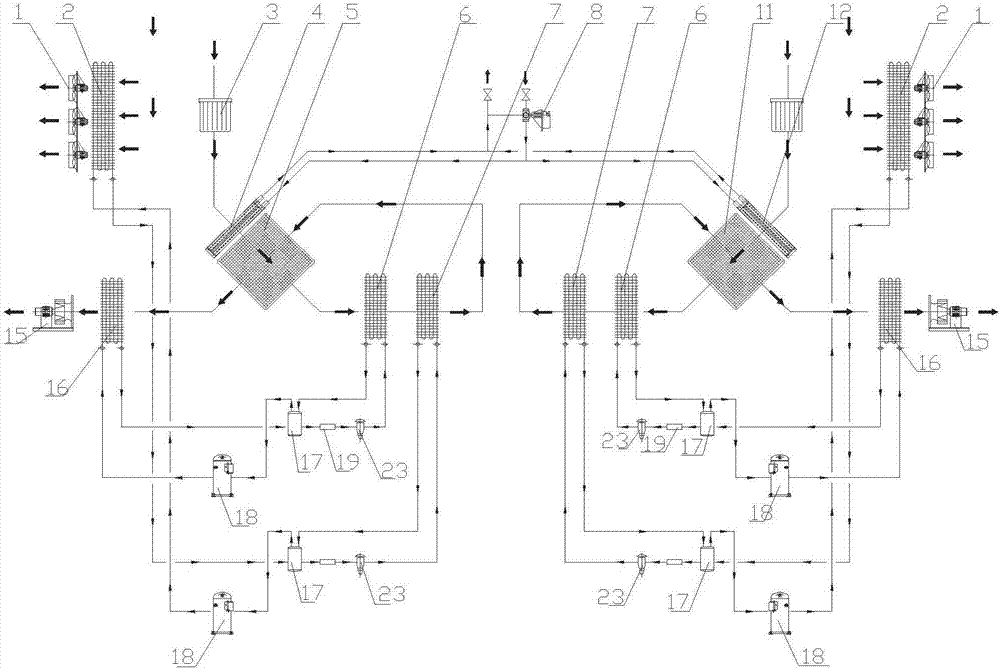

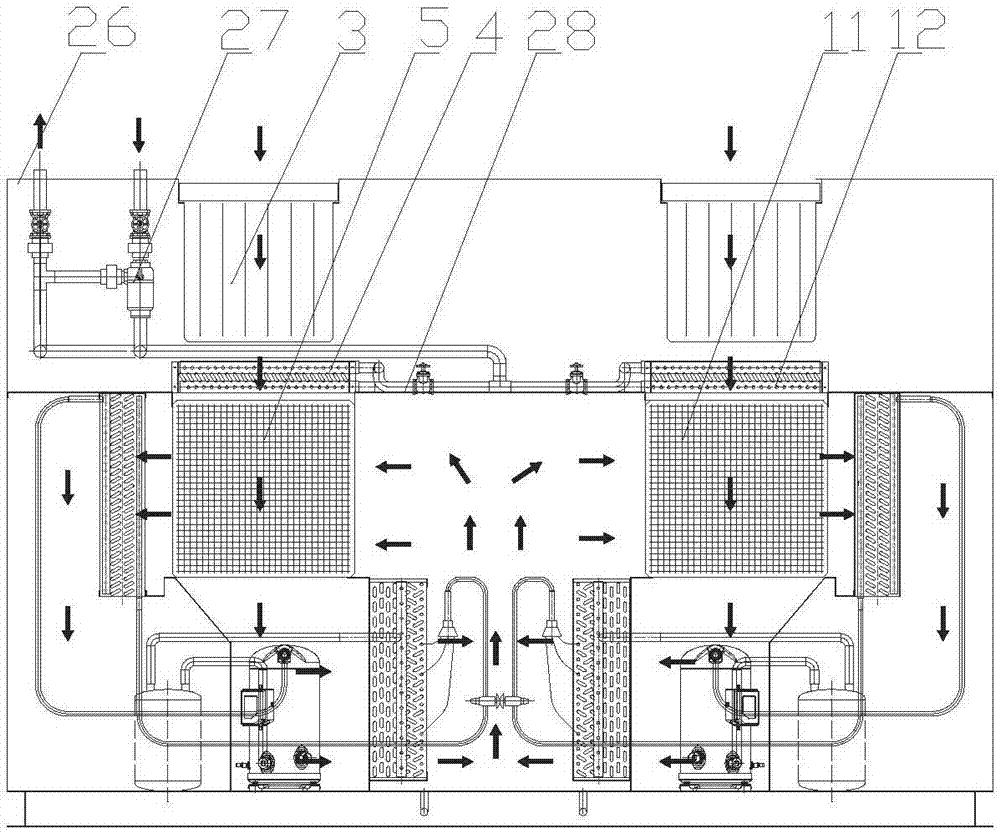

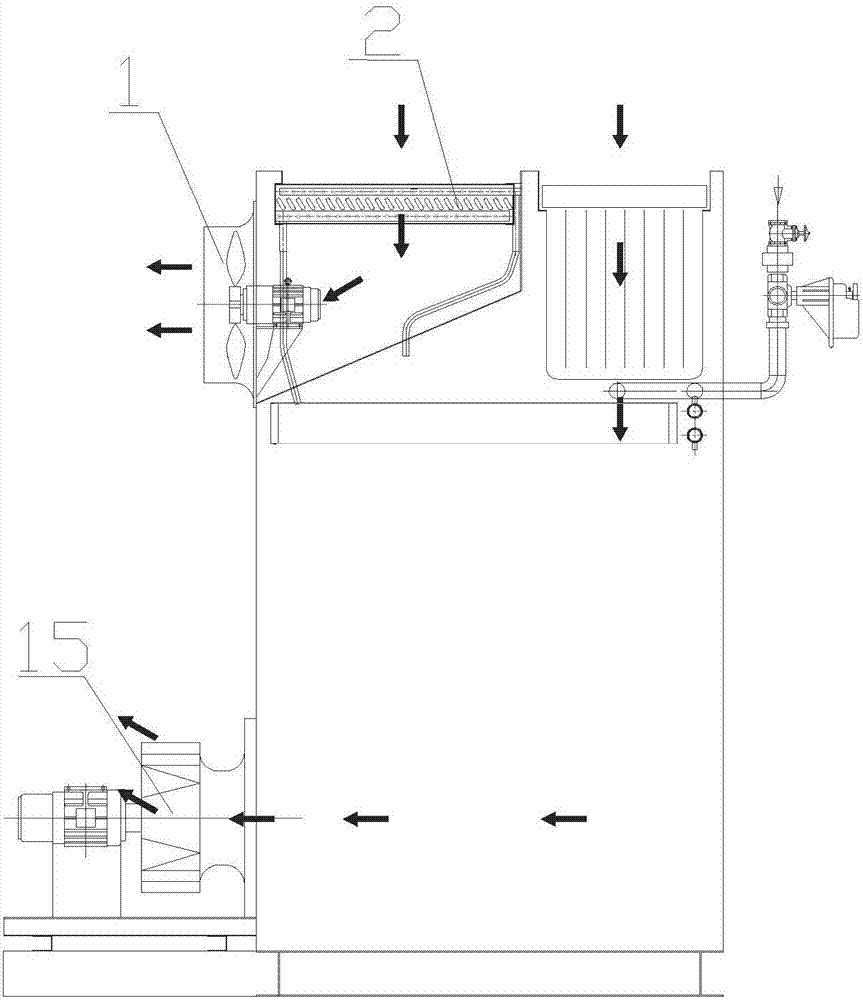

[0027] Adjustable temperature four-effect drying system, such as Figure 1-3 As shown, it includes at least two sets of dehumidification heat pump components and a set of auxiliary heat exchange components. The auxiliary heat exchanging assembly is composed of at least two heat exchangers (4, 12) connected in series through pipes to form a circulation loop, and a refrigerant inlet and a refrigerant outlet are arranged on the circulation loop. An electric proportional valve 8 is arranged on the refrigerant inlet. Control valves are set at the refrigerant inlet and the refrigerant outlet. The dehumidification heat pump assembly includes two refrigerant modules and an air module. The refrigerant module is composed of a primary refrigeration module and a secondary refrigeration module. The primary refrigeration module includes a primary condens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com