Energy-saving drying method for cured meat product

A drying method and product technology, which is applied in the direction of drying and preserving meat/fish, food processing, etc., can solve the problems of large energy consumption and high pollutant discharge, achieve the effects of reducing energy consumption, reducing pollution discharge, and improving energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

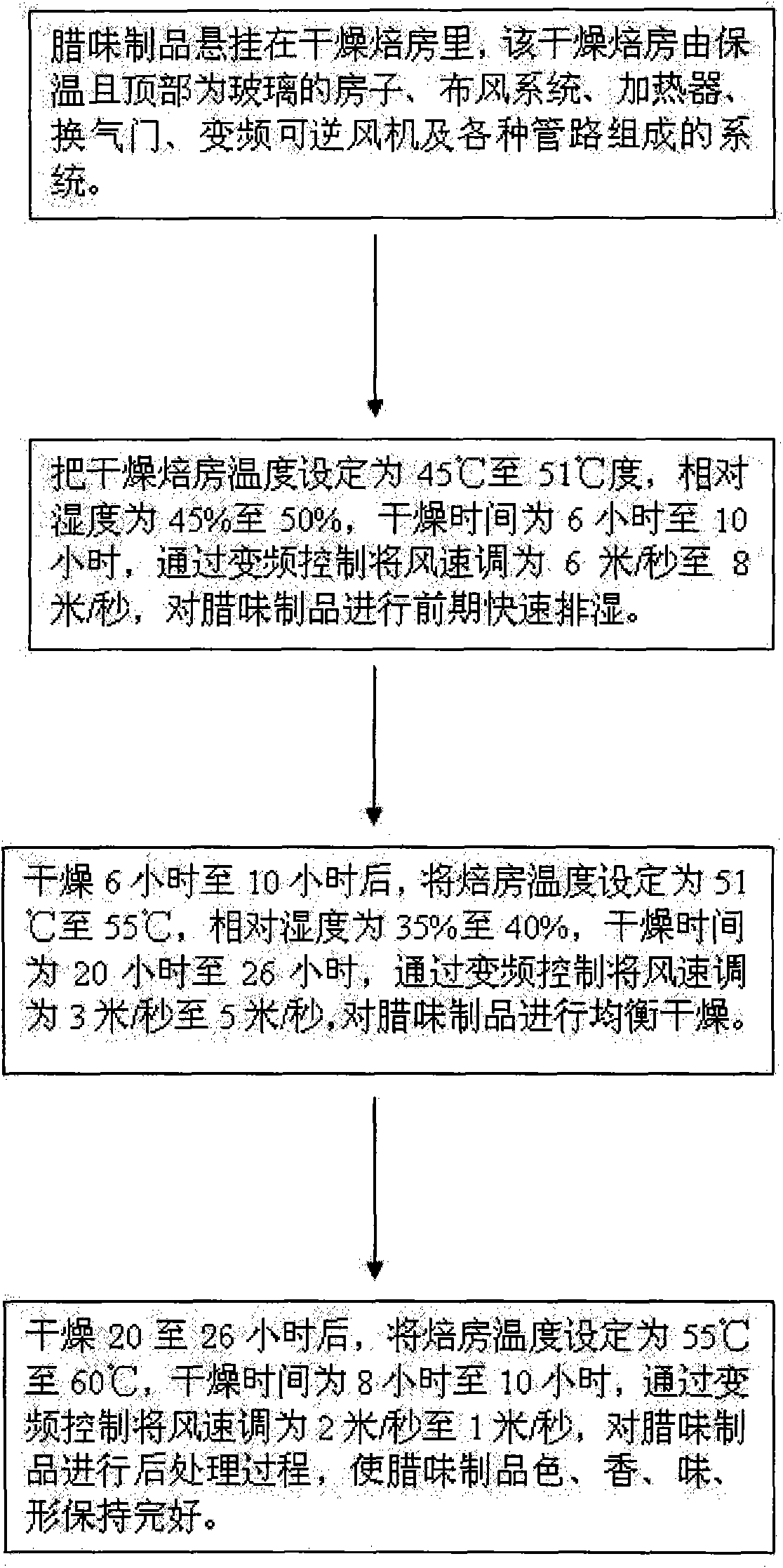

[0030] An energy-saving drying method for Cantonese-style sausages, comprising drying the main body of a baking room, the drying method comprising the following steps:

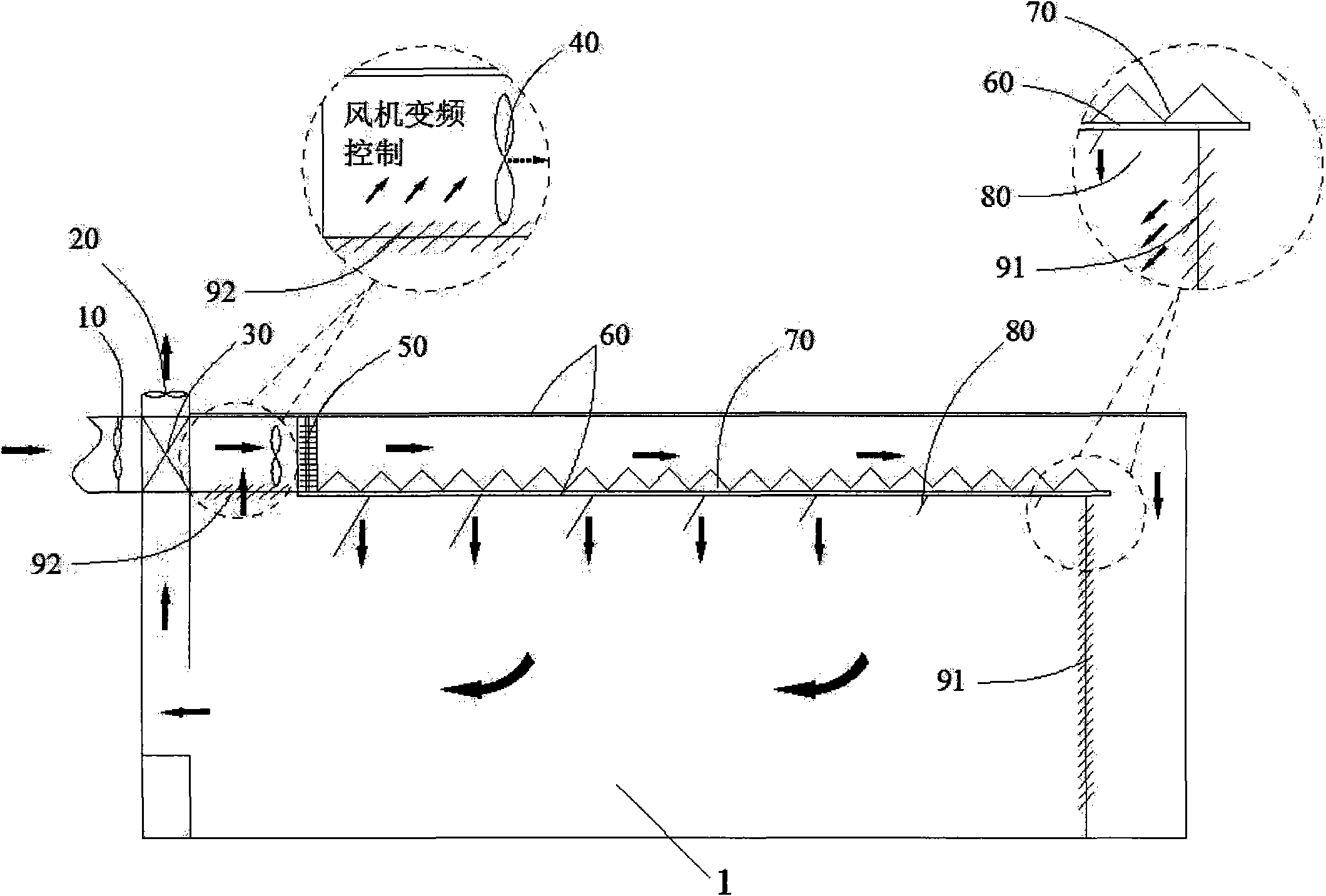

[0031] Step (1), fast dehumidification process: hang the sausages in the dry baking room, which is composed of a house with heat insulation and a glass top, an air distribution system, a heater 50, a ventilation door, and a circulating fan (frequency conversion reversible fan) )40 and various pipelines; turn on the heater, set the temperature of the drying room to 46 degrees, the relative humidity to 45%, and the drying time to 10 hours. Adjust it to about 8 m / s, control the air distribution system, open the ventilation door, and quickly dehumidify the sausage products in the early stage. The cured meat products will quickly discharge the moisture with the air through the convection heat exchange with the hot air in the drying room drying oven;

[0032] Step (2), balanced drying process: after drying for 10 h...

Embodiment 2

[0035] The Cantonese-style energy-saving drying method for cured fish includes drying the main body of the baking room. The specific steps are as follows:

[0036] Step (1) Quick dehumidification process: hang the cured fish products in the dry baking room, which is composed of a house with heat preservation and a glass top, an air distribution system, a heater 50, a ventilation door, and a circulating fan (frequency conversion reversible Fan) 40 and a system composed of various pipelines; turn on the heater and set the temperature of the drying room to 51 degrees, the relative humidity is 50%, and the drying time is 6 hours. Adjust the wind speed to about 6 m / s, control the air distribution system, open the ventilation valve, and quickly dehumidify the cured fish products in the early stage;

[0037] Step (2) After drying for 6 hours, the temperature of the oven is adjusted to 53 by a heating device, the relative humidity is 35%, and the drying time is 20 hours. Then, accordin...

Embodiment 3

[0042] Cantonese-style bacon energy-saving drying method, including drying the main body of the baking room, the specific steps are as follows:

[0043] Step (1) Quick dehumidification process: hang the bacon products in the dry baking room, which is composed of a house with heat insulation and a glass top, an air distribution system, a heater 50, a ventilation door, and a circulating fan (frequency conversion reversible fan) ) 40 and various pipelines; turn on the heater, set the temperature of the drying room to 48 degrees, the relative humidity to 48%, and the drying time to 8 hours; Adjust it to about 7 m / s, control the air distribution system, open the ventilation valve, and quickly dehumidify the cured fish products in the early stage;

[0044] Step (2) After drying for 8 hours, the temperature of the baking room is adjusted to 54 degrees by a heating device, the relative humidity is 38%, and the drying time is continued for 23 hours. Then, according to the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com