Drying device for the production of honeycomb ceramic body SCR denitration catalyst

The technology of denitration catalyst and honeycomb ceramic body is applied in the field of drying equipment for the production of honeycomb ceramic body SCR denitration catalyst, which can solve the problems of inconvenient maintenance, large deviation of cross-section humidity, long drying cycle, etc. , The effect of improving the product qualification rate and shortening the drying cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

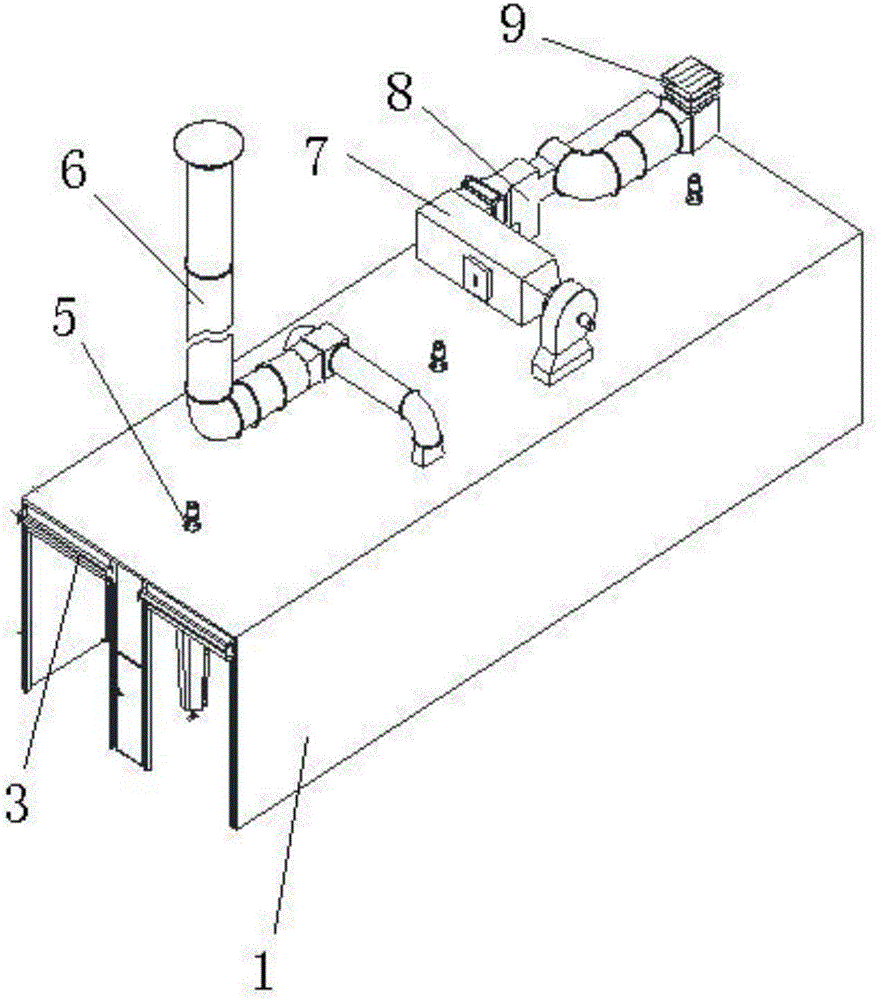

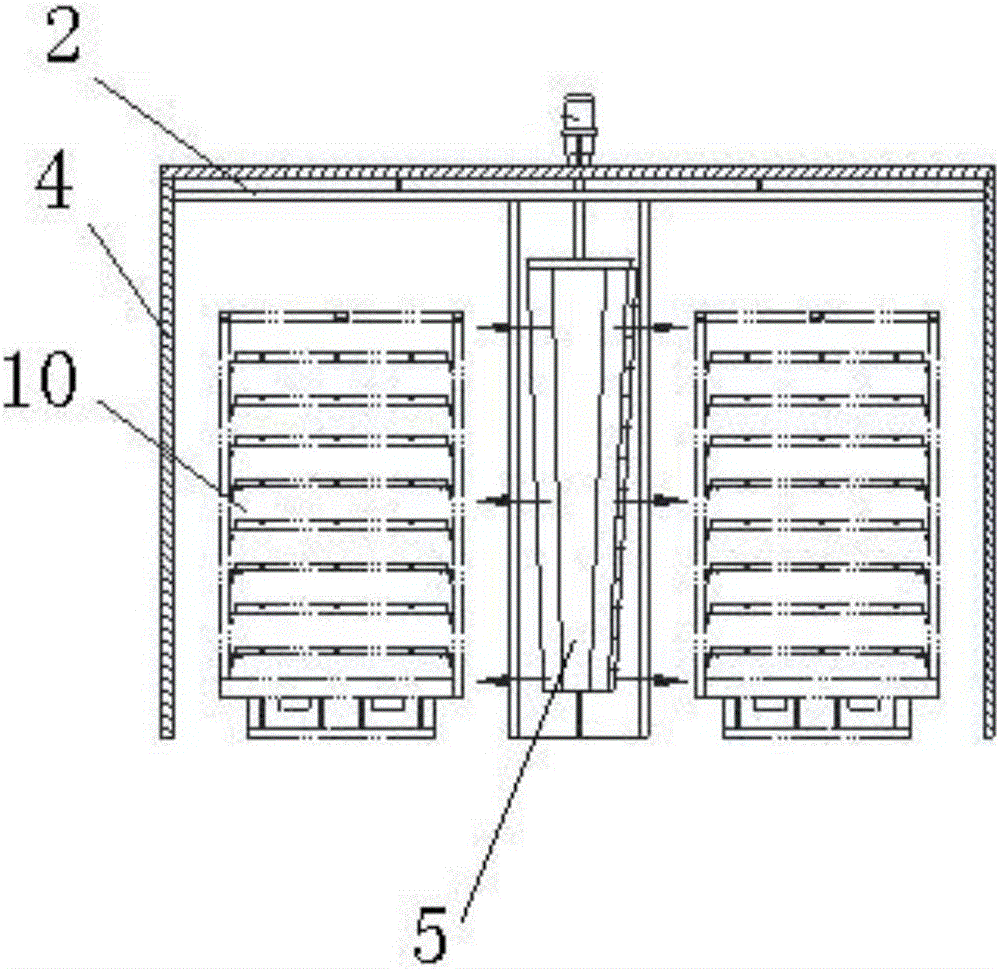

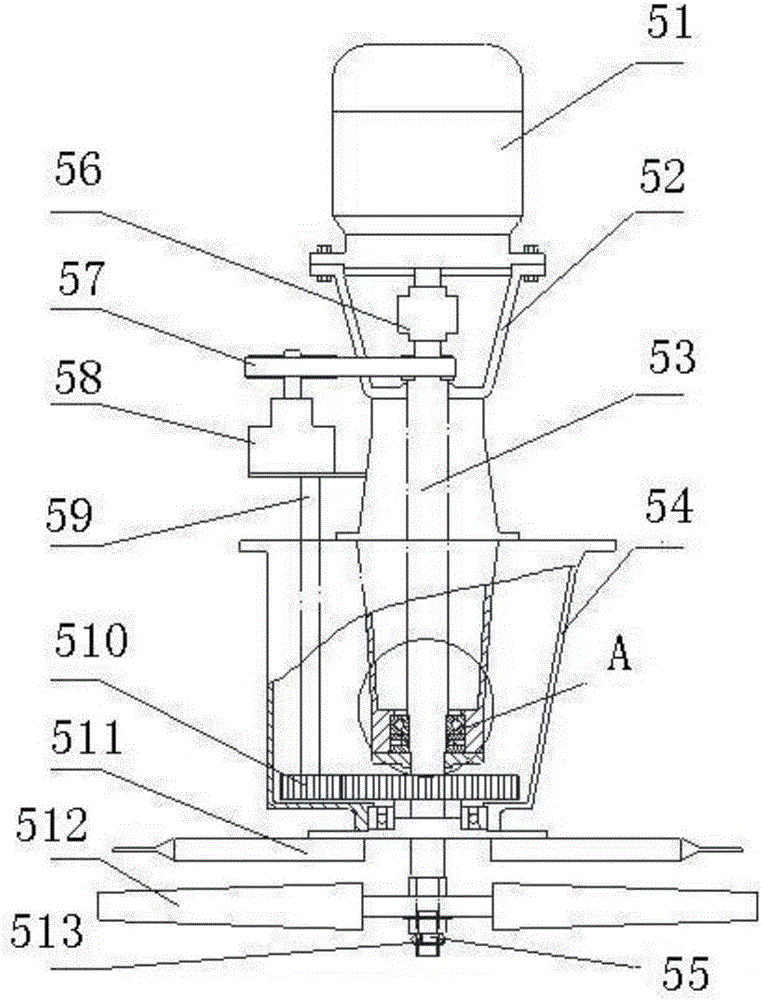

[0023] Such as figure 1 , figure 2 , Figure 5 As shown, a drying equipment for the production of honeycomb ceramic SCR denitration catalyst, including an external box 1, a three-dimensional dynamic air supply system 5, a waste discharge pipe 6, a mixed air pipe 7, a return air pipe 8, a fresh air Pipeline 9 and drying trolley 10. The drying equipment uses high-temperature steam at a temperature of 120-200°C and a pressure of 0.4-1 MPa as a heating source. One drying equipment can be used independently or several units can be used in parallel. The outer box body 1 is assembled from a steel structure skeleton 2 and a sealed heat-insulating shell 4. The sealed heat-insulating shell 4 is spliced by polyurethane heat-insulating composite panels. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com