High-accuracy paper printing equipment

A printing equipment and high-precision technology, which is applied in the direction of printing, printing machines, general parts of printing machinery, etc., can solve the problems of printing accuracy decline and achieve the effect of ensuring rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

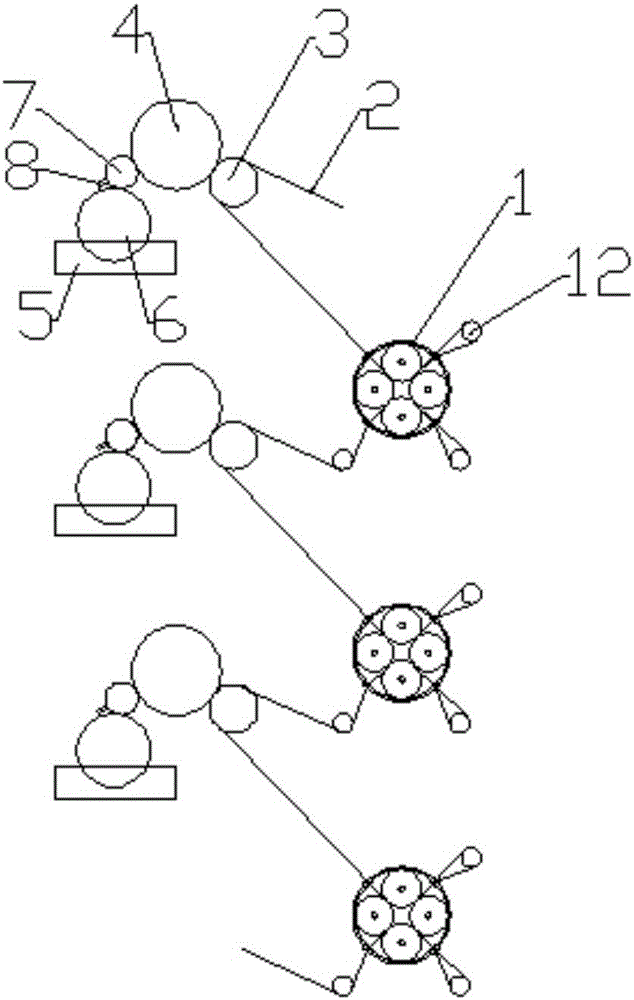

Embodiment 1

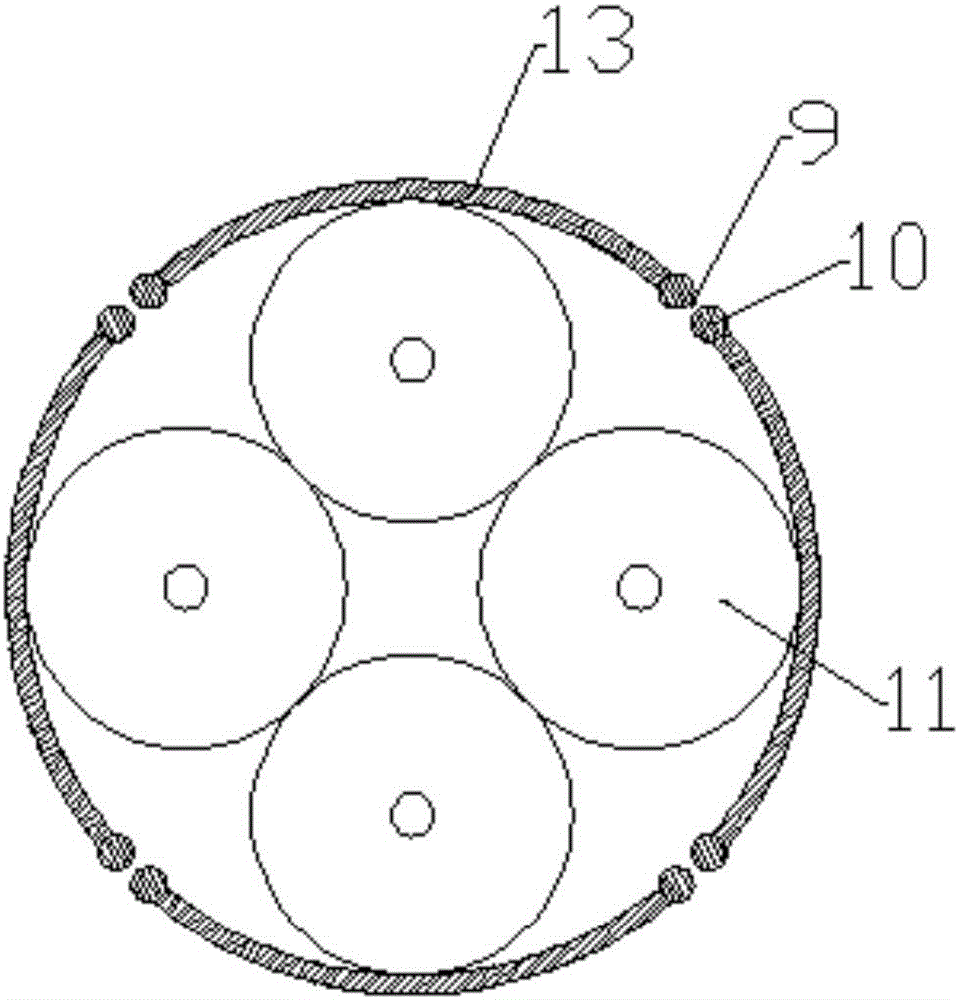

[0027] Such as figure 1 and image 3 As shown, a high-precision paper printing equipment includes a number of constant temperature and humidity boxes 1 arranged side by side, a number of printing parts and printing paper 2 arranged on the side of the constant temperature and humidity box 1; wherein the constant temperature and humidity box 1 has a cylindrical structure, and the interior The temperature is controlled at 15-18°C, the humidity is controlled at 60-70% RH, and the constant temperature and humidity box 1 mainly includes a casing 13 and four rolling shafts 11 uniformly arranged inside the casing 13, and the side walls of the adjacent rolling shafts 11 The shortest distance between them is 0.5-2 mm; there are several through grooves 9 on the side wall of the shell 13 along the direction of the central axis, and a cylindrical bar 10 is respectively arranged on the side walls of the two ends of the through groove 9 along the direction of the central axis of the shell, a...

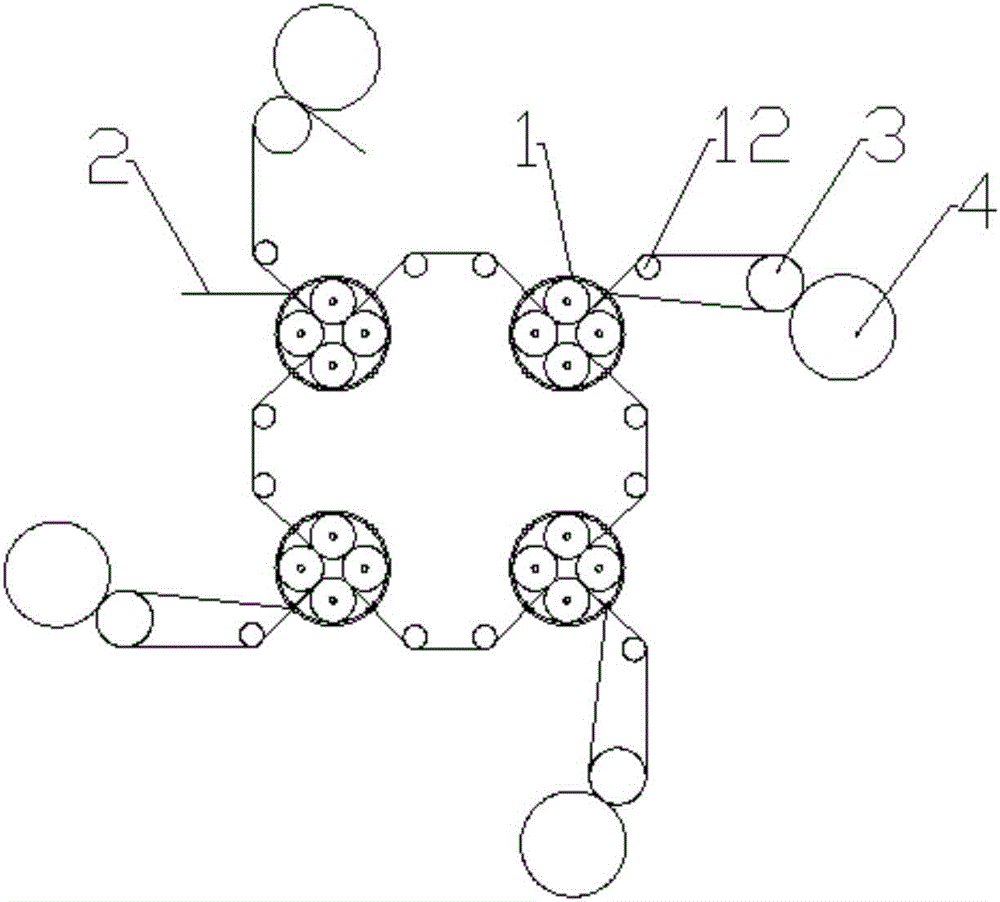

Embodiment 2

[0030] Such as figure 2 As shown, the only difference between this embodiment and Embodiment 1 is that several constant temperature and humidity chambers 1 are arranged in a circular distribution; when working, the printing paper 2 passes through the middle of the impression roller 3 and the printing plate cylinder 4 and then enters In the constant temperature and humidity chamber 1, at this moment, after directly passing through a rolling shaft 11, it passes out and enters the next constant temperature and humidity chamber 1, and then enters the next printing unit again for printing, and so on until all printing is completed.

[0031] The above two embodiments are the two distribution methods that are often used. During work, it can also be considered in multiple aspects such as site layout requirements, paper flexibility, external temperature and humidity, so as to achieve a more reasonable and effective distribution and maximize work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com