Analysis method of three-dimensional impact load elastic-plastic bending crack tip plastic region

A flexural crack, impact load technique, applied in the research field of flexural crack propagation path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

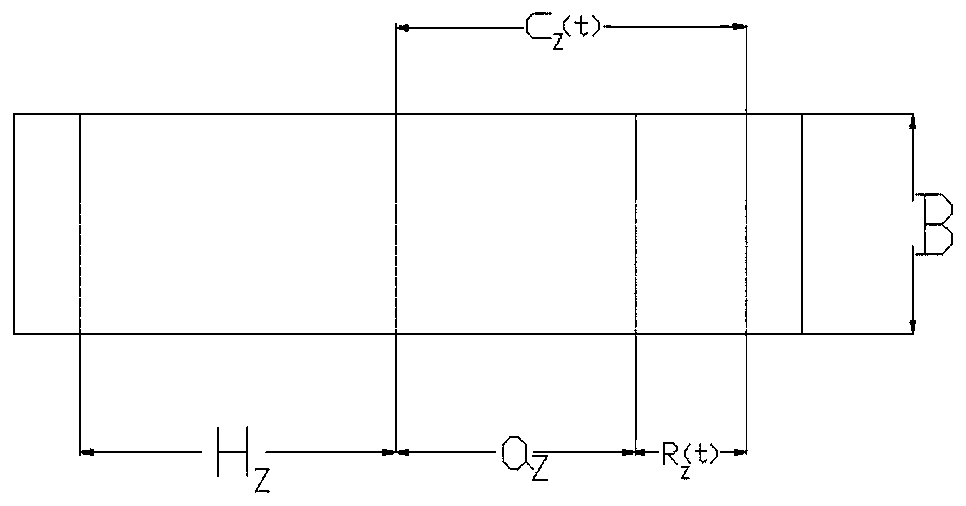

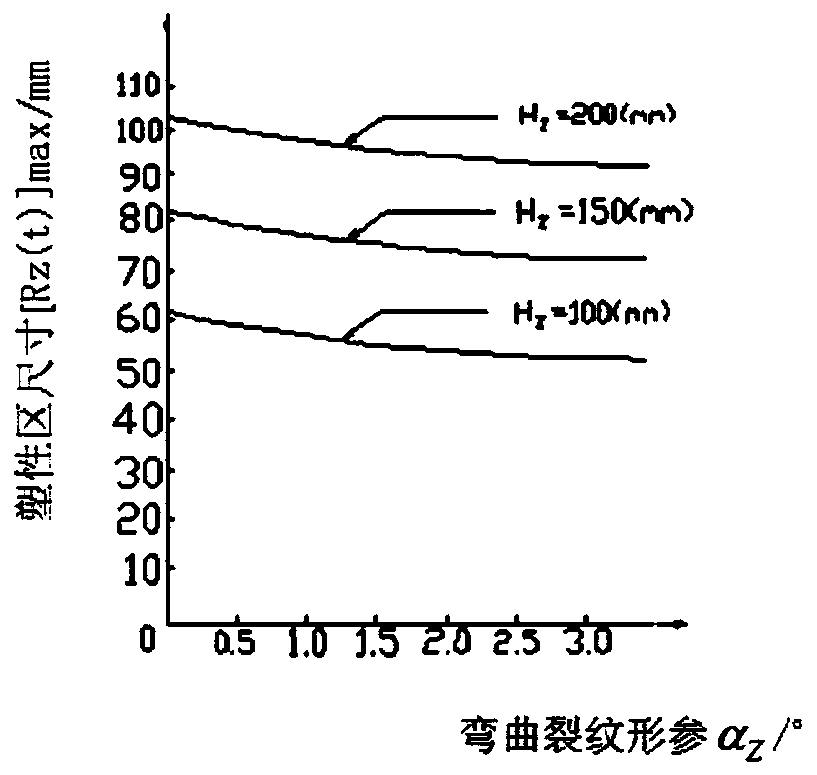

[0119] Taking carbon steel as an example, the Poisson's ratio of carbon steel is ν=0.23. When the impact load applied to the cracked body is: σ aZ (t) = 0.125σ s (4t-t 2 ), σ rZ (t) = 0.025σ s (4t-t 2 ), the numerical solution of the projection length of the maximum size of the dynamic plastic zone at the tip of the three-dimensional elastic-plastic bending crack on the extension line of the crack straight line can be calculated at t=2 seconds. Now, the numerical solution of the projection length of the maximum size of the dynamic plastic zone at the tip of the three-dimensional elastic-plastic bending crack on the extension line of the crack straight line is plotted as follows: Figure 2a-2e shown.

Embodiment 2

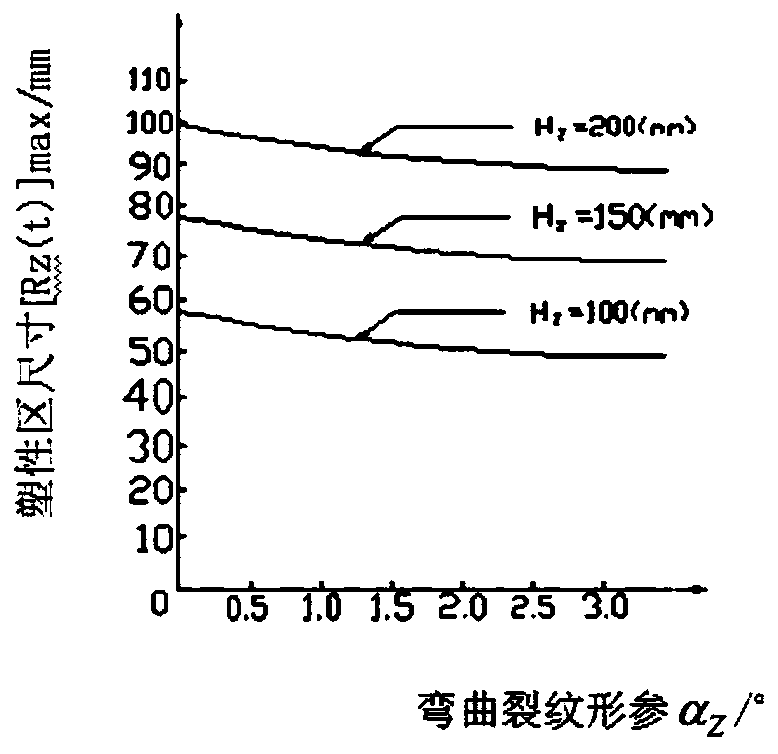

[0121] Taking alloy steel as an example, the Poisson's ratio of carbon steel is ν=0.3. When the impact load applied to the cracked body is: σ aZ (t) = 0.33σ s (2t-t 2 ), σ rZ (t) = 0.03σ s (2t-t 2 ), the numerical solution of the projection length of the maximum size of the dynamic plastic zone at the tip of the three-dimensional elastic-plastic bending crack on the extension line of the crack straight line at t=1 second can be calculated. Now, the numerical solution of the projection length of the maximum size of the dynamic plastic zone at the tip of the three-dimensional elastic-plastic bending crack on the extension line of the crack straight line is plotted as follows: Figures 3a-3e shown.

[0122] combined with Figure 2a-2e and 3a-3e, it can be seen that under the impact load of the same intensity and the same rate of change, the maximum size of the dynamic plastic zone of the three-dimensional bending crack corresponding to the same length of the straight line ...

Embodiment 3

[0125] Taking rolled aluminum as an example, the Poisson's ratio of rolled aluminum is ν=0.36. When the external impact loads acting on the cracked body are: σ aZ (t) = σ s [1-(t-3) 2 ], the numerical solution of the projection length of the maximum dimension of the dynamic plastic zone at the tip of the three-dimensional elastic-plastic bending crack on the extension line of the crack straight line can be calculated at t=3 seconds. Now, the numerical solution of the projection length of the maximum size of the dynamic plastic zone at the tip of the three-dimensional elastic-plastic bending crack on the extension line of the crack straight line is plotted as follows: Figures 4a-4e shown.

[0126] from Figures 4a-4eIt can be seen from the five groups of figures that the greater the thickness of the three-dimensional crack body, the larger the thickness of the three-dimensional crack body, for the same length of the straight line part of the crack and the same degree of be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com