Device and process for producing steel-plastic winding and welding corrugated pipes

A technology of winding welding and bellows, which is applied in the field of steel-plastic composite pipe machinery and production technology, and can solve problems such as poor axial tensile capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

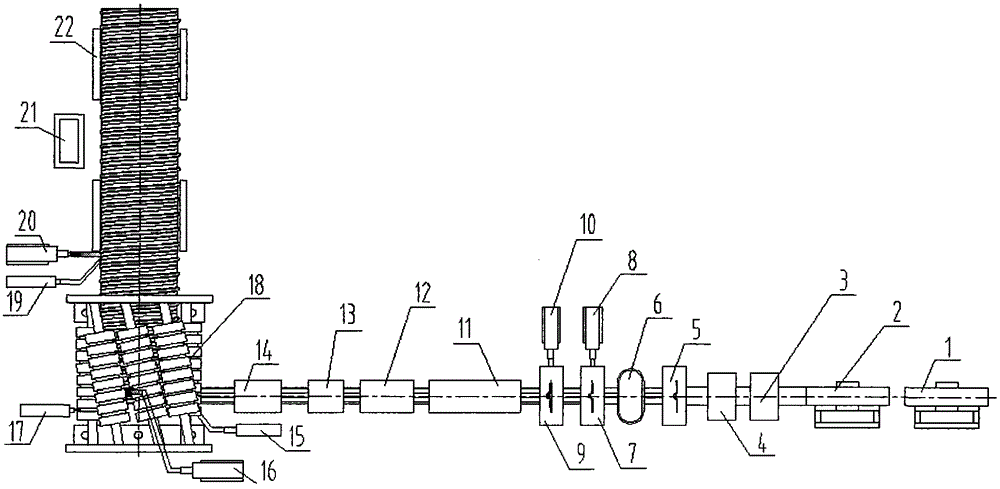

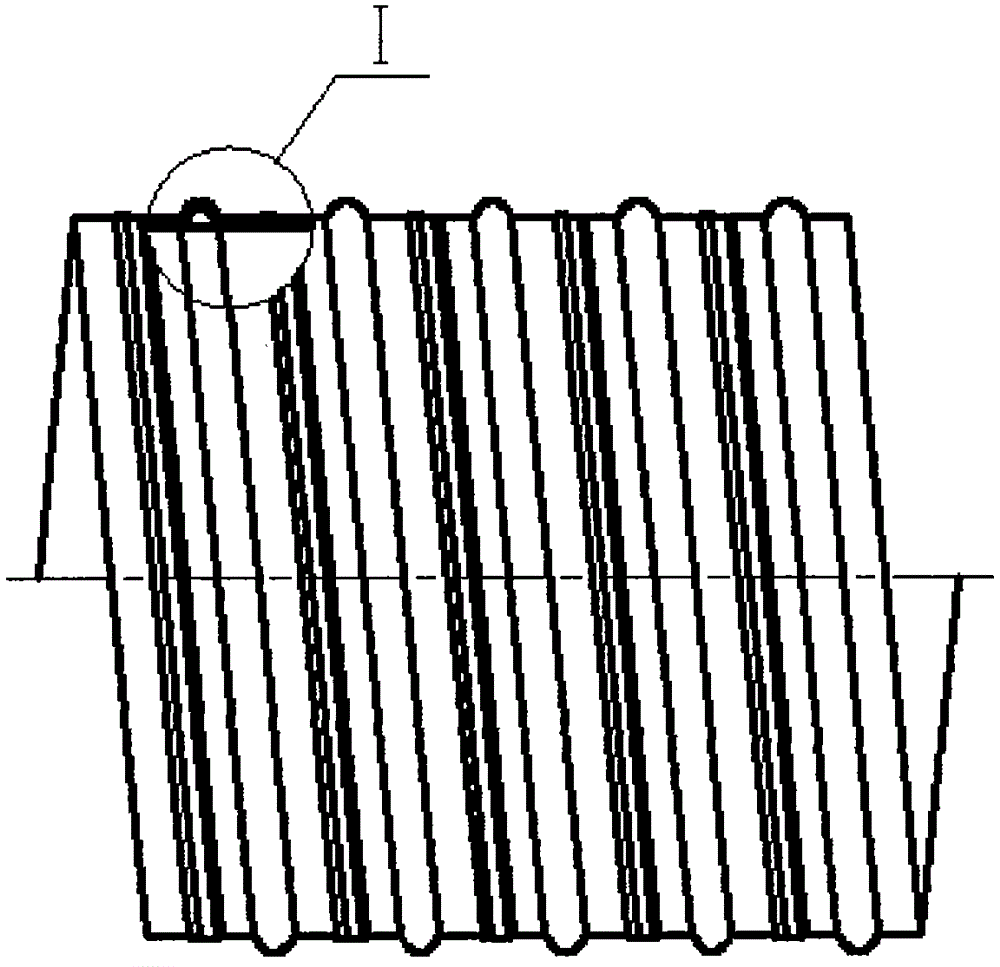

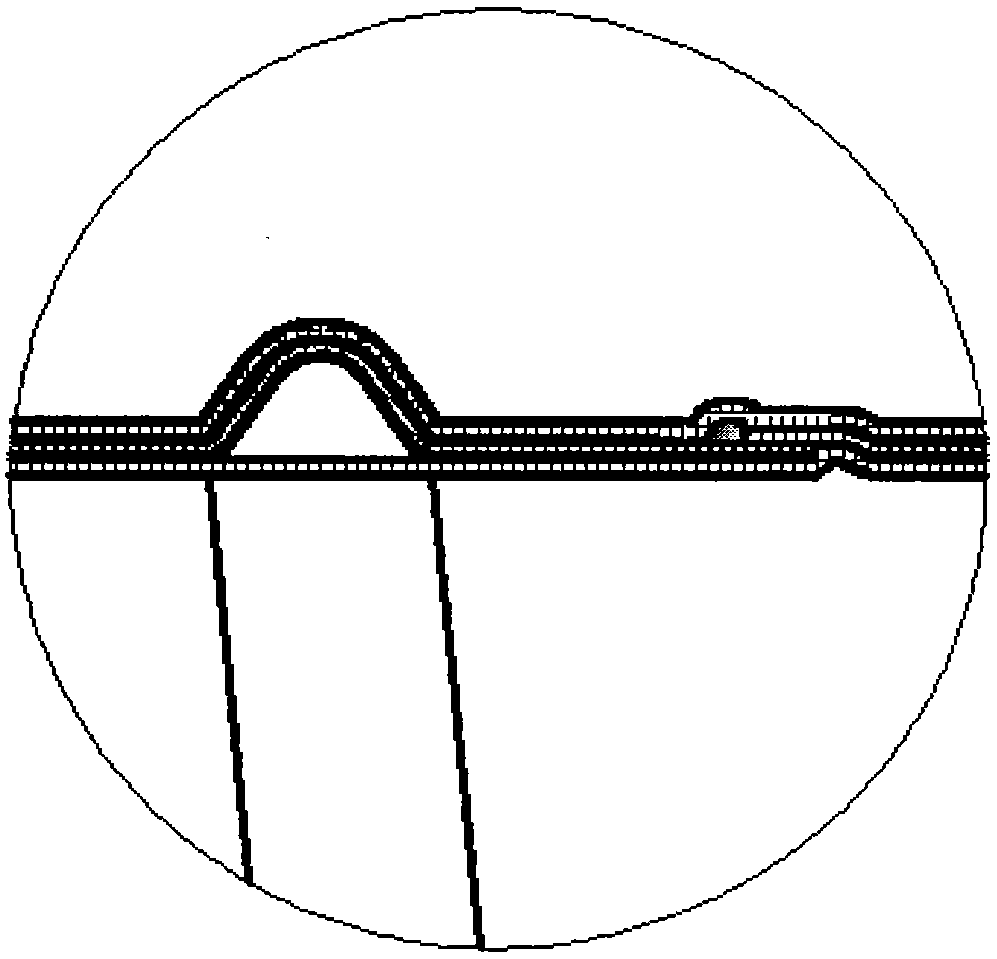

[0029] As attached figure 1 As shown, the steel-plastic winding welding bellows equipment includes: steel belt retracting device, steel belt docking device, steel belt derusting device, strip forming device, steel belt air-drying heating device, glue coating die, glue layer extruder, Inner and outer coating die, inner and outer coating extruder, coating strip shaping device, coating strip pulling device, coating strip cutting device, coating strip conveying device, inner heating device, inner welding belt Material extruder, welding device, bending forming device, outer layer heating device, outer layer welding strip extruder, pipe cutting device, pipe bracket. The steel belt retracting device 1 is connected with the steel belt retracting device 2; the steel belt docking device 3 is connected with the steel belt rust removing device 4; the strip forming device 5 is connected with the steel belt air-drying heating device 6; the glue coating mold 7 Connect the rubber layer extrude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com