Method for judging stable bearing in steel pipe concrete column plane

A steel tube concrete column and plane technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of inaccurate judgment of stable bearing capacity and insecure structure, and achieve the effect of improving reliability, safety and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0066] Embodiments of the present invention and concrete steps thereof are as follows:

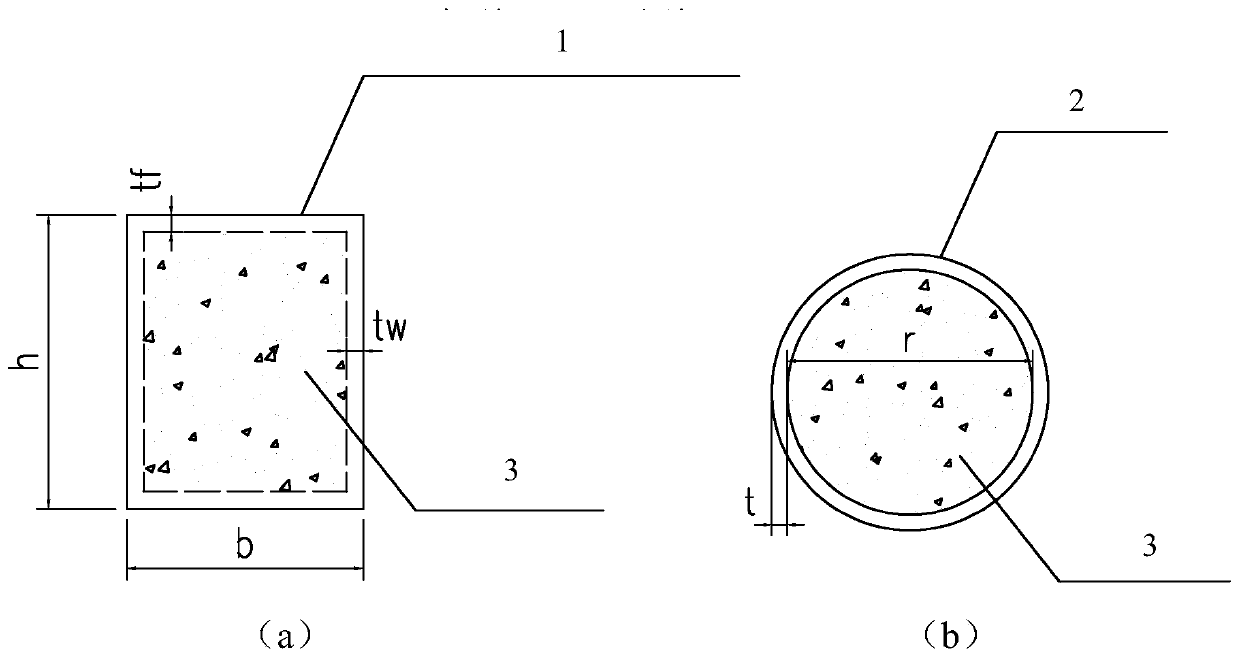

[0067] 1. If figure 1 As shown, the CFST column is formed by pouring concrete 3 inside the steel pipes 1 and 2. First, according to the geometric parameters and material parameters of the CFST column, calculate P P , M Px0 , M Py0 、α ck ,P Ex ,P Ey , the specific formula is as follows:

[0068] P P =fA s + f c A c

[0069]

[0070]

[0071]

[0072] In the formula: I sx , I sy ——The moment of inertia of the rectangular steel pipe around the two bending axes of the section;

[0073] I cx , I cy ——The moment of inertia of the concrete filled in the rectangular steel pipe around the two bending axes of the section;

[0074] H - the height of the steel tube concrete column;

[0075] A s 、A c ——the cross-sectional steel tube area an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com