A method for improving the ultimate bearing capacity of rectangular concrete-filled steel tube columns in one-way compression bending stability

A technology of rectangular steel pipes and concrete columns, applied in the directions of columns, pillars, piers, etc., can solve the problems of unsafe structure, inaccurate judgment of stable bearing capacity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0064] Embodiments of the present invention and concrete steps thereof are as follows:

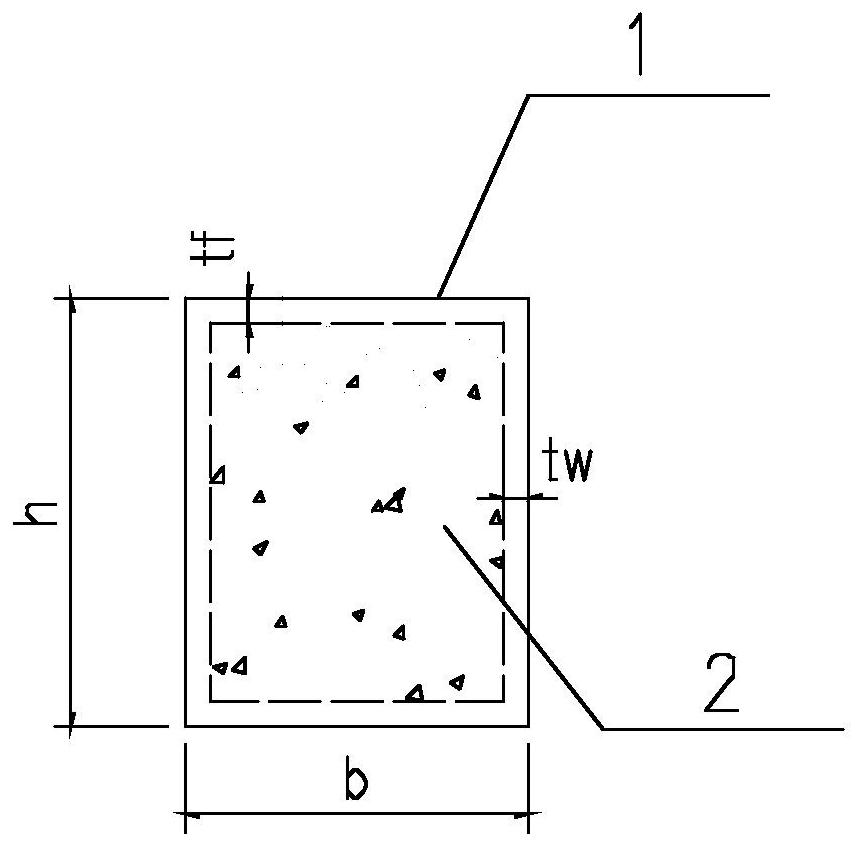

[0065] 1. If figure 1 As shown, the rectangular steel tube concrete column is composed of the rectangular steel tube 1 and the concrete 2 poured inside the rectangular steel tube 1. First, according to the geometric parameters, material parameters and the direction of the bending moment axis of the rectangular steel tube concrete column, calculate P P ,P Ex or P Ey 、α ck , the specific formula is as follows:

[0066] P P =fA s +f c A c

[0067]

[0068]

[0069]

[0070] In the formula: I sx , I sy ——The moment of inertia of the rectangular steel pipe around the two bending axes of the section;

[0071] I cx , I cy ——The moment of inertia of the concrete filled in the rectangular steel pipe around the two bending axes of the section;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com