Method for determining large-plastic bending section profile curve of thin-walled pipe

A cross-sectional profile and thin-walled pipe technology, which is applied in the field of metal pressure processing, can solve the problems of safety hazards in the use of pipes, flattening exceeding the allowable value, and collapse of system components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

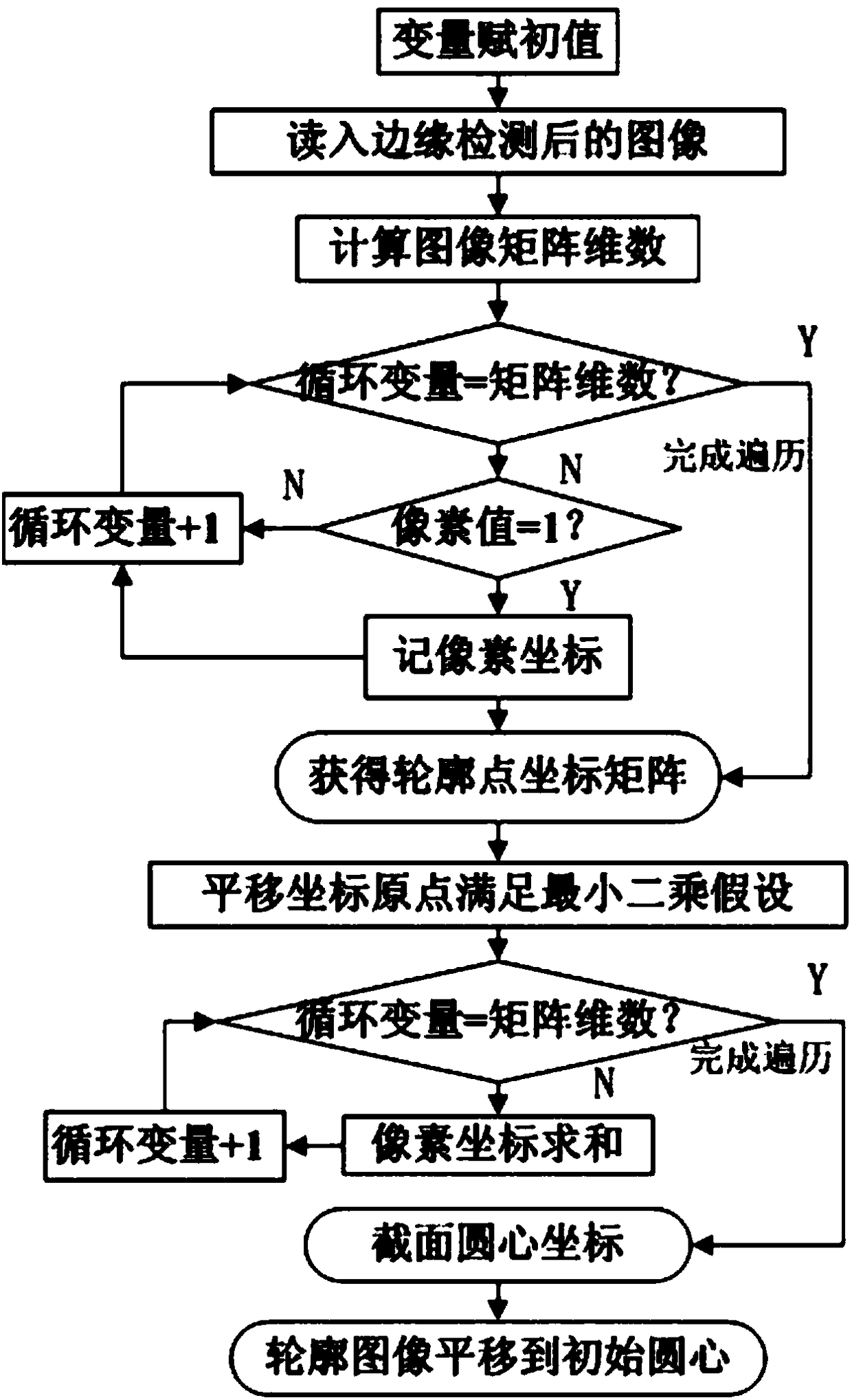

[0041] In the following, the present invention will be further described in detail by taking the determination of the cross-sectional profile curve of the stainless steel thin-walled pipe material after large plastic bending as a specific implementation example in conjunction with the accompanying drawings.

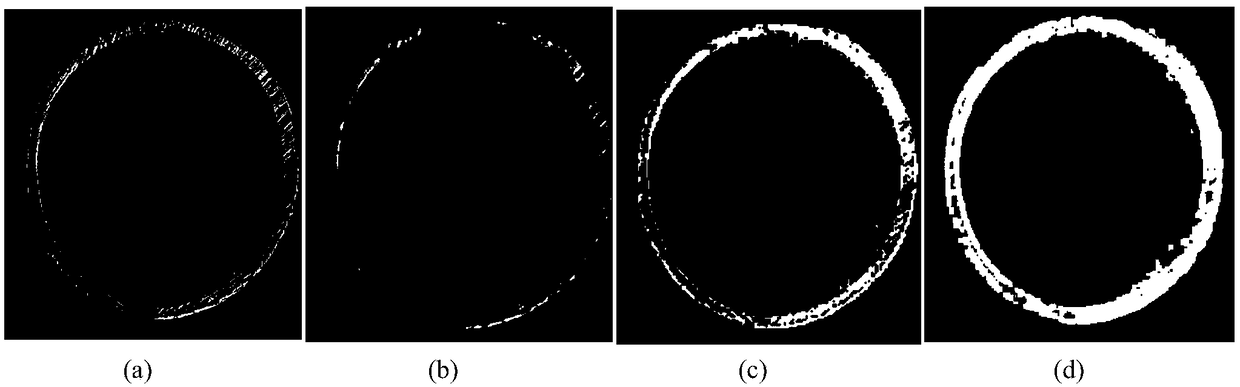

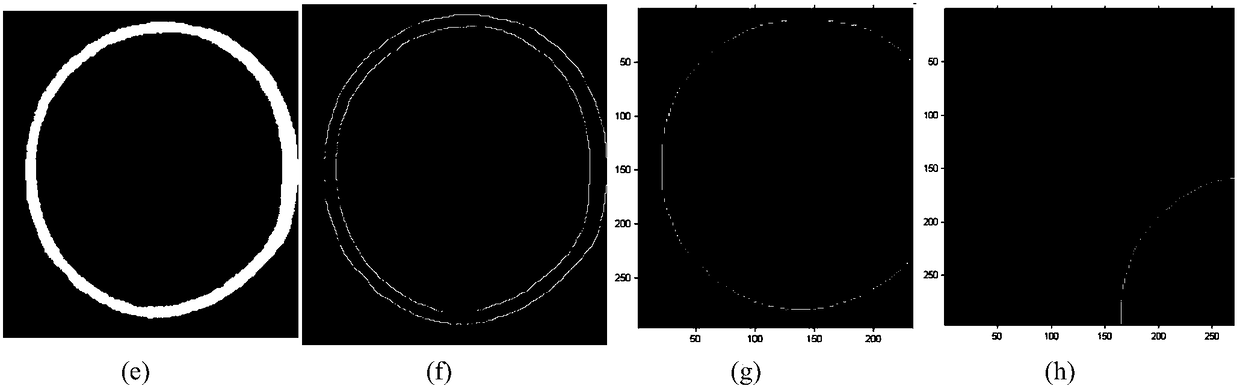

[0042] Step 1: Acquisition of cross-sectional profile images of thin-walled tubes

[0043] Here, a cold-rolled seamless 1Cr18Ni9Ti stainless steel thin-walled pipe is selected. The outer diameter of the pipe is d=21mm, the wall thickness t=1mm, and the length is about 400mm. On the chuck, align the flattened profile section with the image acquisition device. The image acquisition device includes: TM-6740GE area array CCD camera, COMPUTAR TEC-M55 telecentric lens, Smart 5000 uninterruptible power supply, SL24-850nm IR surface infrared light source. The bright field lighting method was used for image acquisition, and the resolution of 640 pixels × 480 pixels was selected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com