Ultra-thin strip steel finishing unit operation parameter design method

A technology for finishing units and operating parameters, which is applied in the design field of operating parameters of ultra-thin strip steel finishing units, and can solve the problems of lack of theoretical and data support for the rational judgment of selected parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

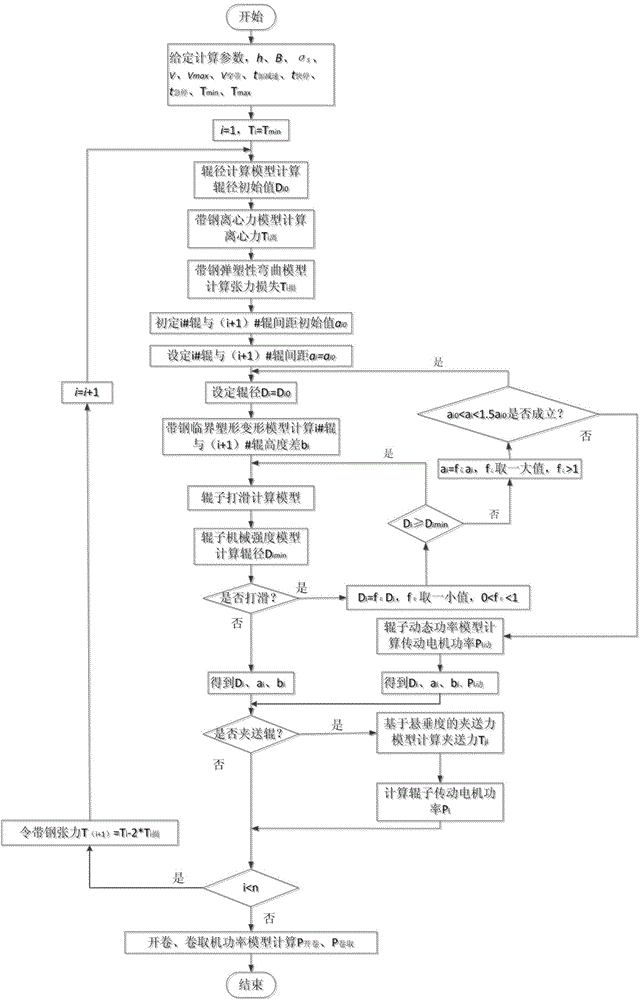

[0137] When developing and designing a finishing unit, it is necessary to theoretically analyze the rationality of the selected operating parameters. This embodiment further describes in detail the operation parameter design method for the ultra-thin strip steel finishing unit provided by the present invention.

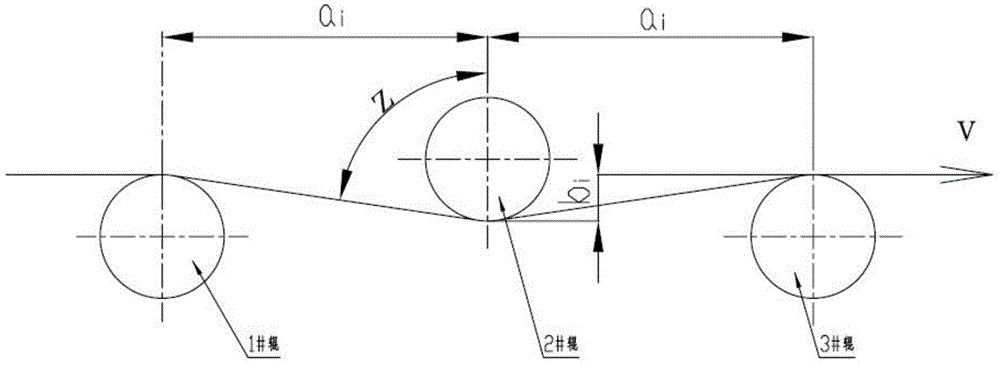

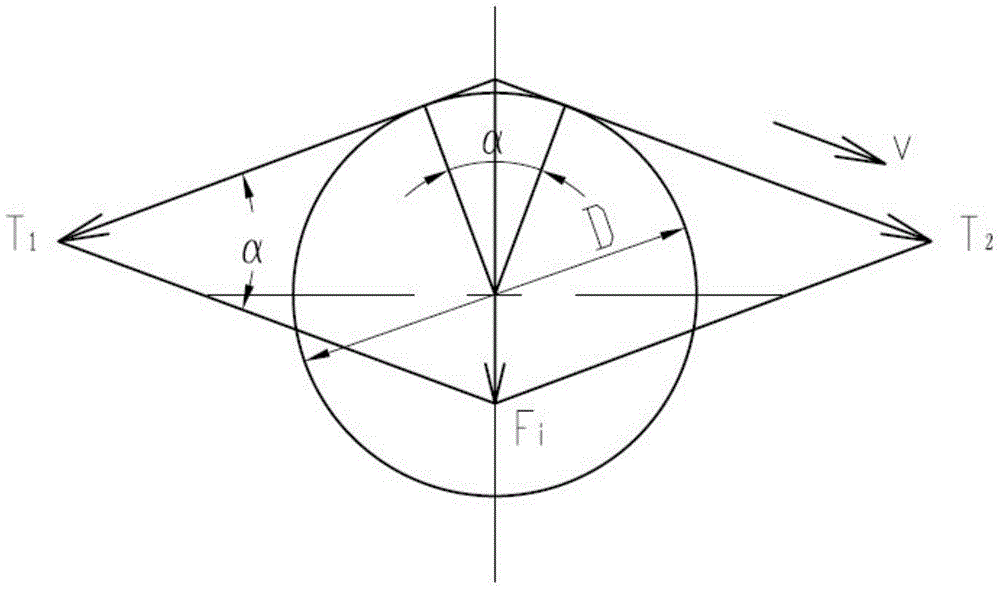

[0138] The flow chart of the operation parameter design method of the ultra-thin strip steel finishing unit according to the present invention is as follows: image 3 shown, including multiple models. Before establishing each model, it is necessary to set the operating parameters of the unit, such as strip width B, strip thickness h, strip yield strength σ s , the maximum operating speed of the unit v max , the unit threading speed v 穿带 , normal acceleration and deceleration time t 加减速 , the quick stop deceleration time t 快停 , emergency stop deceleration time t 急停 , the minimum coiling tension T min , the maximum winding tension T max . In addition, the roll n...

Embodiment 2

[0256] The design parameters of a tin-plating preparation unit are calculated and analyzed by adopting the calculation method of the design parameters of the ultra-thin strip steel high-speed finishing unit proposed by the present invention. The strip specifications of this unit are: width B=700~1300mm, thickness h=0.15~0.55mm, yield strength σ s =275~435MPa, the maximum operating speed of the unit is v max = 1000m / min, belt threading speed v 穿带 =30m / min, normal acceleration and deceleration time t 加减速 =23s, quick stop deceleration time t 快停 =17s, emergency stop deceleration time t 急停 =9s, minimum winding tension T min =6000N, the maximum winding tension T max =18000N. The calculation results are shown in Table 1.

[0257] Table 1 Calculation results of design parameters of a tin-plating preparation unit

[0258]

[0259]

[0260] Referring to the calculation results in Table 1, and considering the actual situation of the unit equipment, basic space, maintenance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com