Nuclear power plant non-security-level DCS configuration testing method and system

A non-safety-level, test-method technology, applied in general control systems, control/regulation systems, and comprehensive factory control, etc., can solve problems such as equipment malfunction, inability to meet projects, occupation, etc., to reduce equipment damage and shorten engineering Concise effect of construction period and network structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

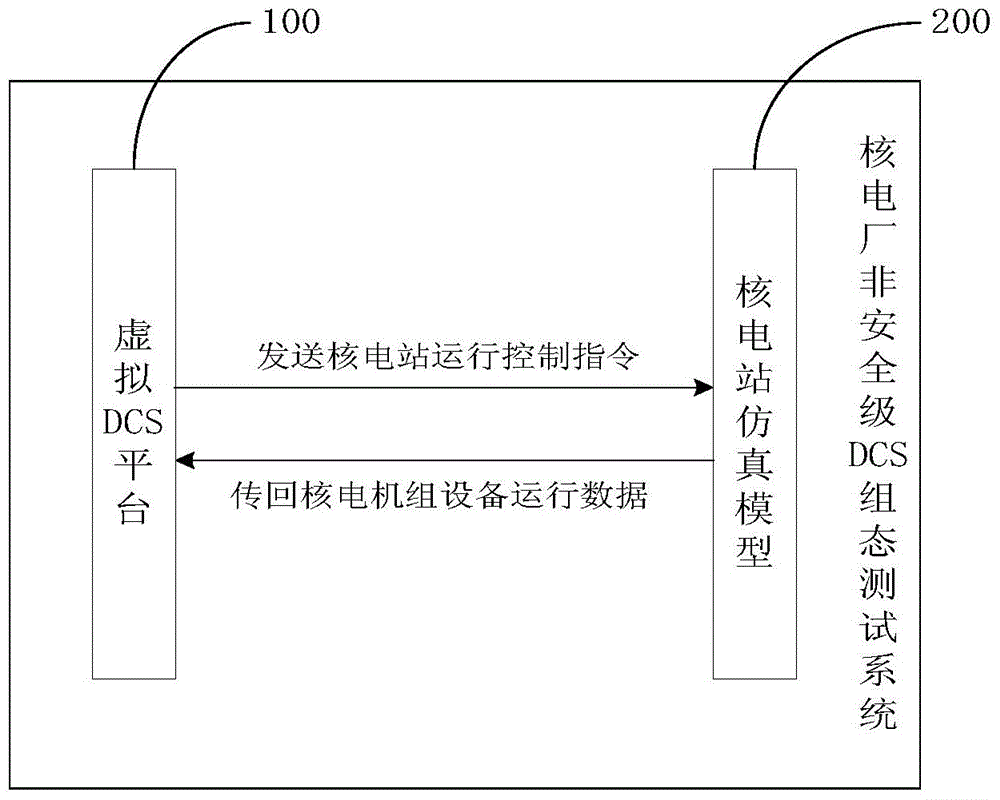

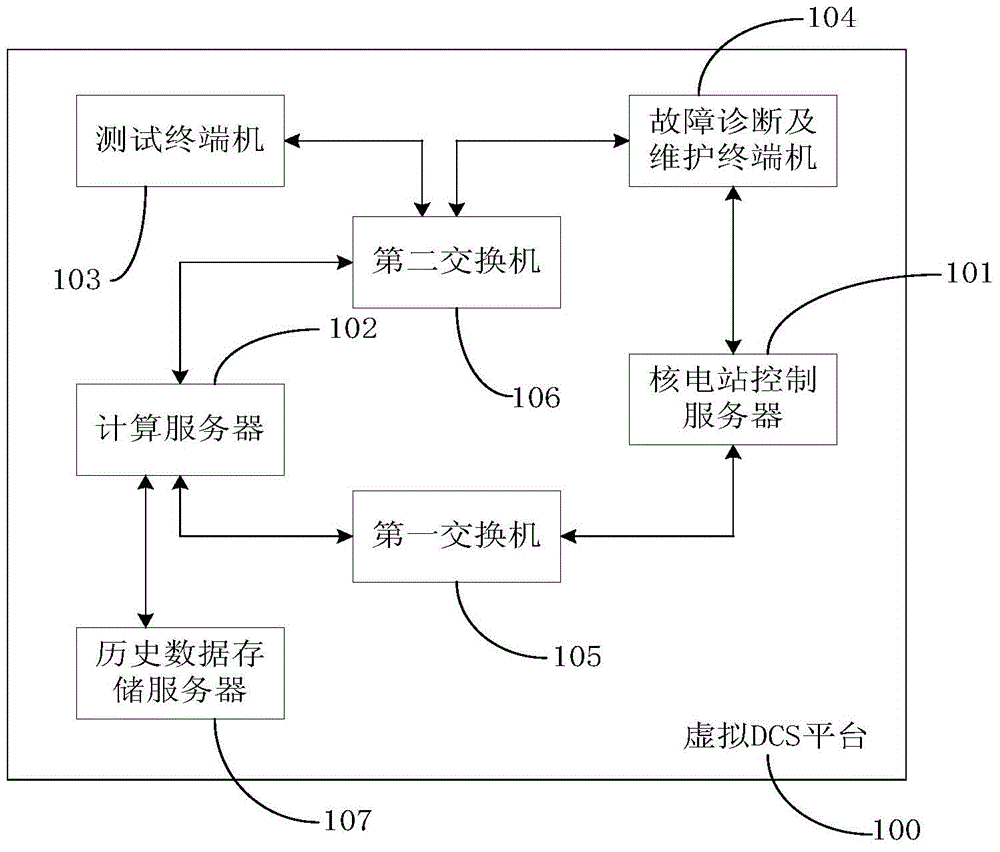

[0050] This embodiment provides a non-safety level DCS configuration test system for nuclear power plants based on the combination of virtual DCS (Digital Instrument Control System) technology and nuclear power simulation technology, which is used to simulate the operating environment of a real nuclear power plant , collect various operating data generated during the simulated operation of the nuclear power unit, analyze various abnormalities in the simulated operation of the nuclear power unit according to the operating data of the nuclear power unit, and set the relevant setting parameters in the DCS configuration file according to the abnormal operation of the nuclear power unit According to the corresponding modification, the nuclear power unit is controlled according to the modified DCS configuration file to ensure the safe and stable operation of the nuclear power unit.

[0051] The following will combine Figure 1 to Figure 3 The structure of the non-safety level DCS co...

Embodiment 2

[0064] This embodiment provides a non-safety level DCS configuration test method for nuclear power plants based on the combination of virtual DCS technology and nuclear power simulation technology, and its processing flow is as follows Figure 4 As shown, the following processing steps are included:

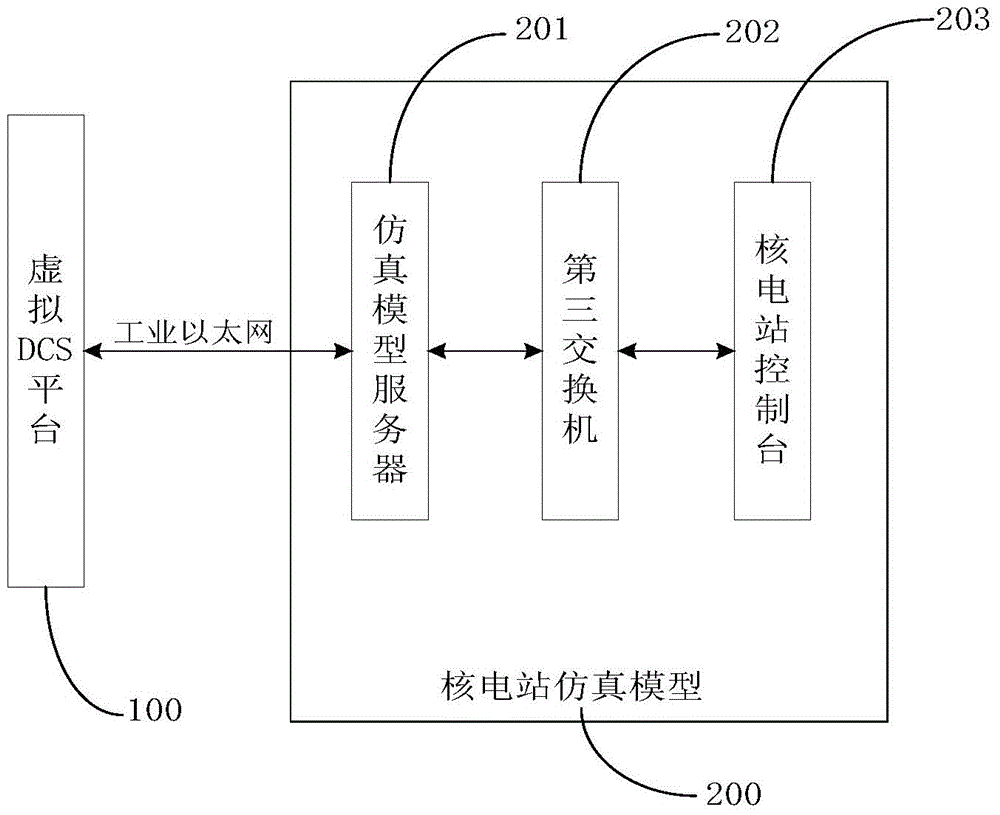

[0065] Step 102: Build a nuclear power plant simulation model 200 including a simulation model server 201 and a nuclear power plant console 203 according to the model of the nuclear power unit, and select a virtual DCS platform 100 that matches the nuclear power unit simulation model to remotely control the nuclear power plant simulation model 200.

[0066] Step 102 , the operator of the non-safety DCS configuration test system of the nuclear power plant sets the initial operating parameters of the nuclear power unit on the console 203 of the nuclear power plant, and starts the simulation model server 201 according to the initial operating parameters of the nuclear power unit.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com