Plastic plate continuous bending device

A technology of bending device and plastic plate, which is applied in the field of plastic bending machine, can solve the problems of bending device failure, continuous bending, long production cycle, etc., and achieve the effect of precise angle, small air knife opening and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

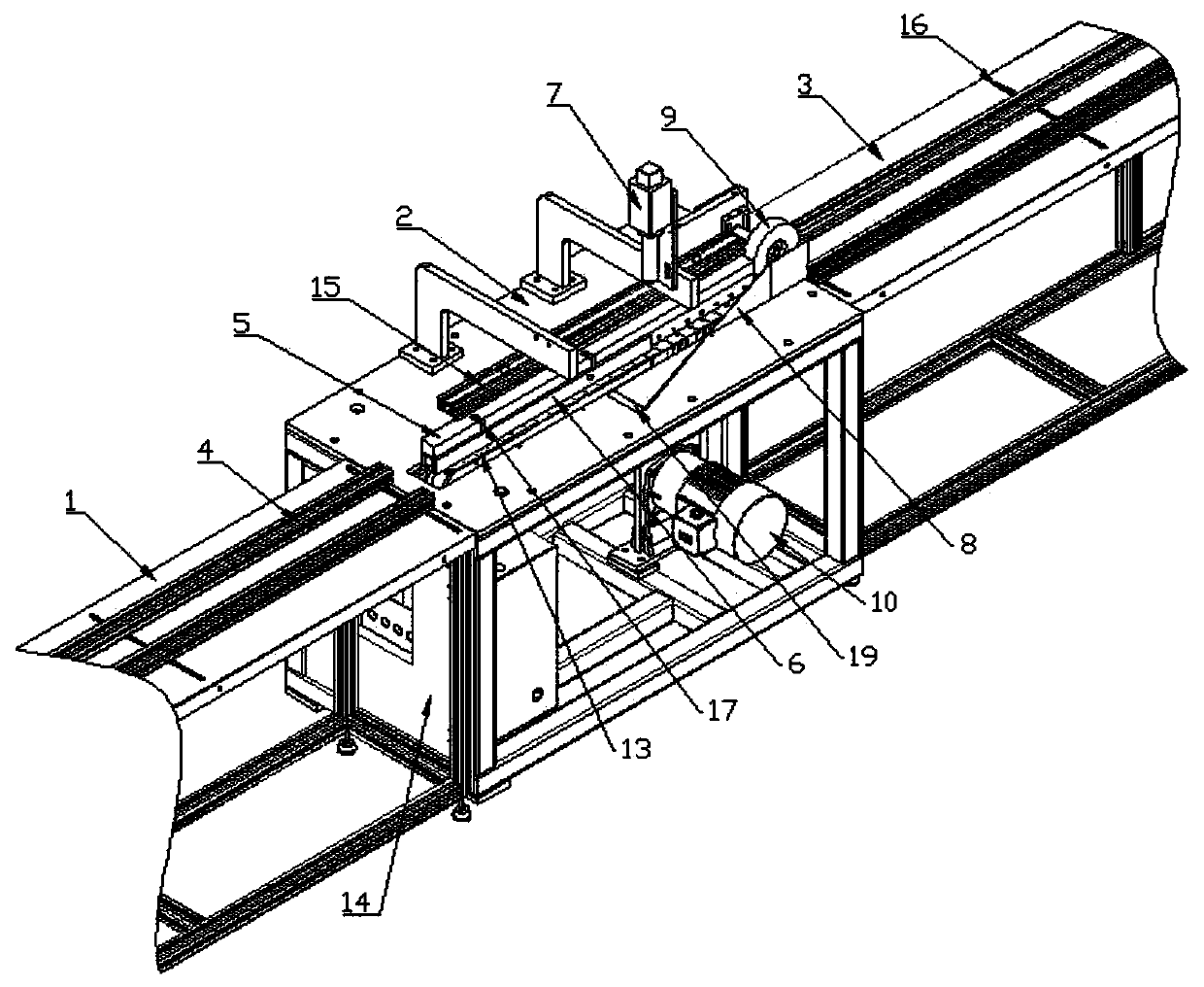

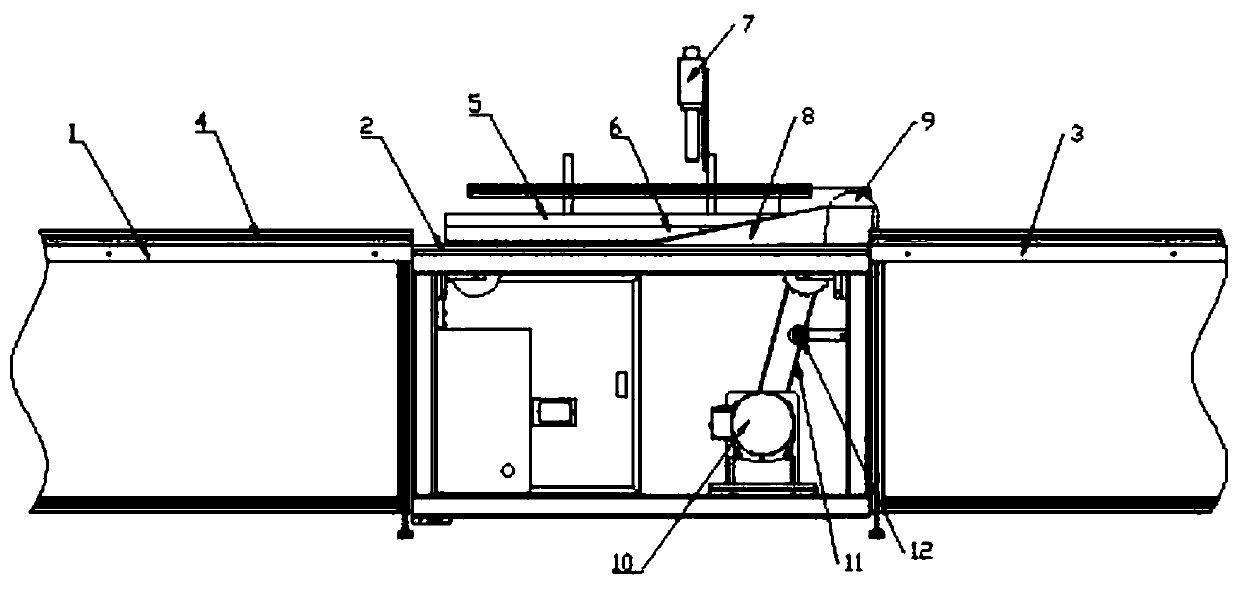

[0022] Embodiment one: by Figure 1 to Figure 4 Given, the plastic sheet continuous bending device includes bending device 2, feeding platform 1 and shaping platform 3, the plastic sheet is fed from feeding platform 1 to the bending device, and after being bent by the bending device, it is The material is discharged at the platform 3 and is shaped during the discharging process. The bending device 2 is located between the feeding platform 1 and the shaping platform 3, and a shaping transmission wheel 9 is arranged between the bending device 2 and the shaping platform to avoid The plastic plate is deformed, and the bending device includes a chain slat 13, a conveying pressure wheel 5, a heating device and a bending guide plate 8, and the chain slat 13 is made of steel to prevent the heating device from heating the plastic plate. The chain slats are heated and deformed. The chain slats 13 are driven by the transmission motor 10 through the belt 11 to drive the tension wheel 12 t...

Embodiment 2

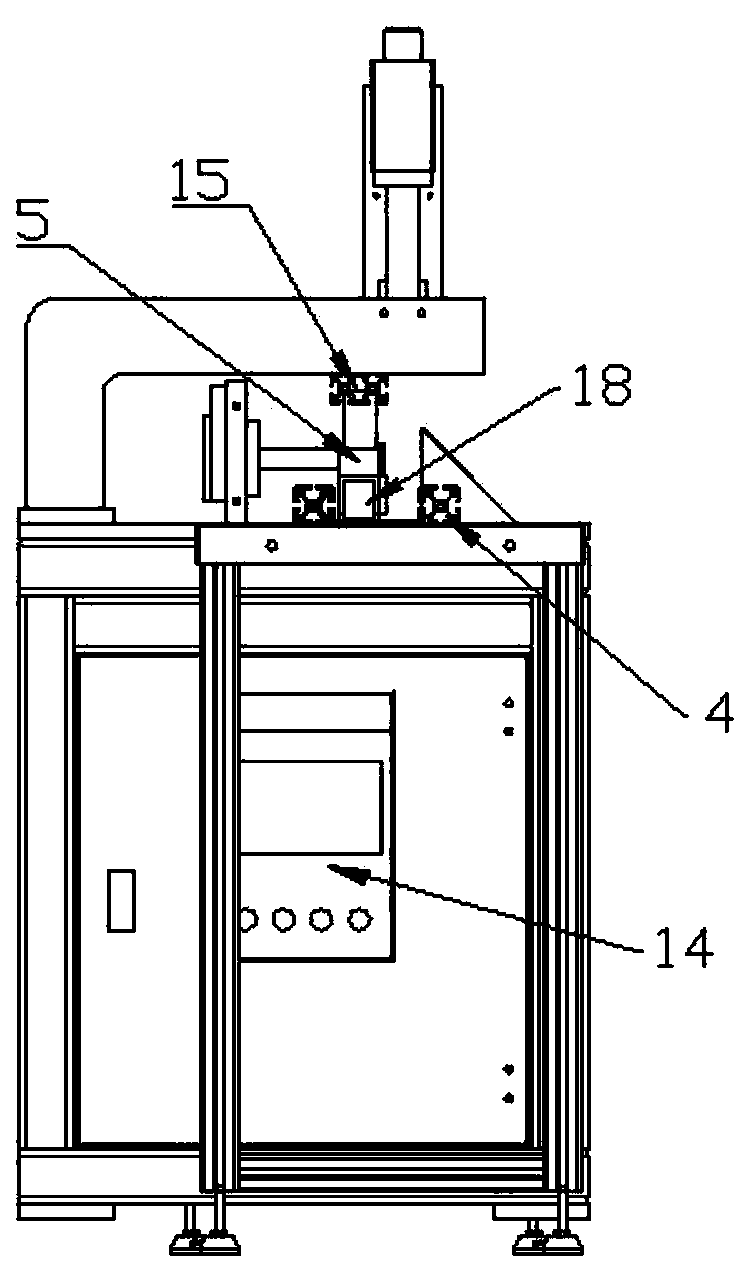

[0023] Embodiment 2: In one embodiment, the transmission pressure roller 5 includes an upper force application block and a lower transmission block, and the transmission block is provided with a hollow groove with an opening facing downwards on the side facing the chain slats 13 , and the hollow groove A plurality of transmission wheels 18 are arranged in the groove, and the described force block is a solid metal block, which is used to increase the quality of the transmission pressure roller 5, and compresses the plastic plate to prevent it from warping or shifting. The lower part is changed from sliding friction to rolling friction, which facilitates the transmission of the plastic plate. The force applying block and the transmission block are integrally made, and a pressure bar 15 for adjusting the height of the transmission pressure wheel 5 is arranged above the transmission pressure wheel 5. Bolts are set between the rod 15 and the delivery pinch roller 5, and the bolts ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com