Method for reinforcing metal through roll bending and combined deformation

A deformation strengthening and metal technology, which is applied in the field of rolling and bending combined deformation strengthening metal to achieve the effect of simple realization process, optimized size and strengthening of metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

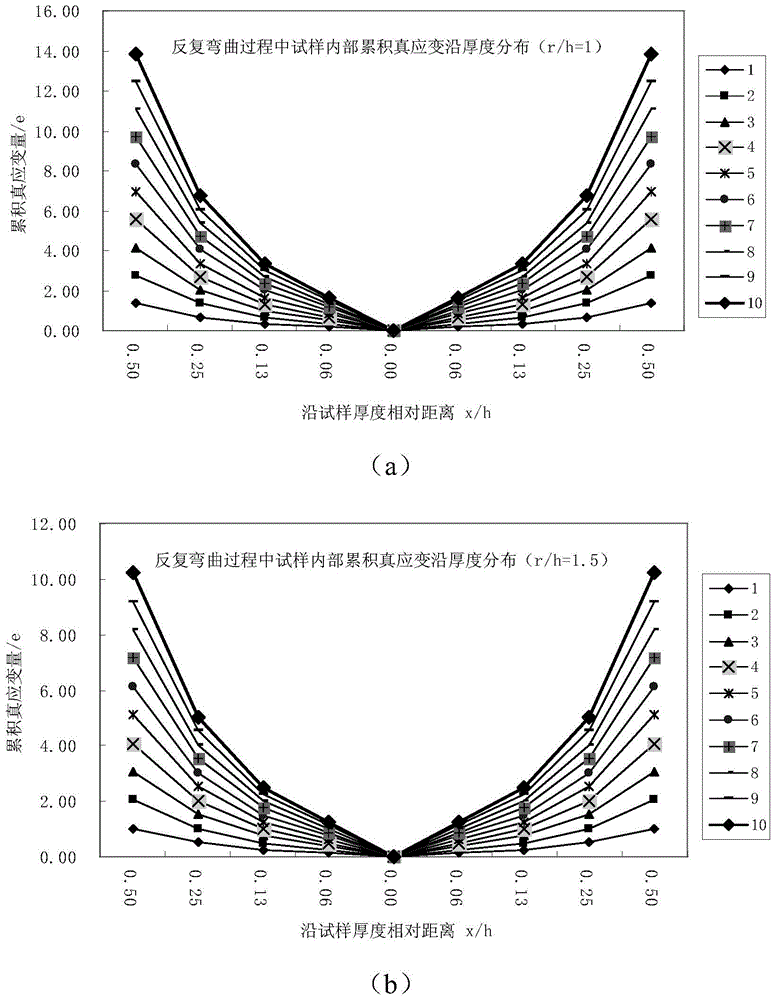

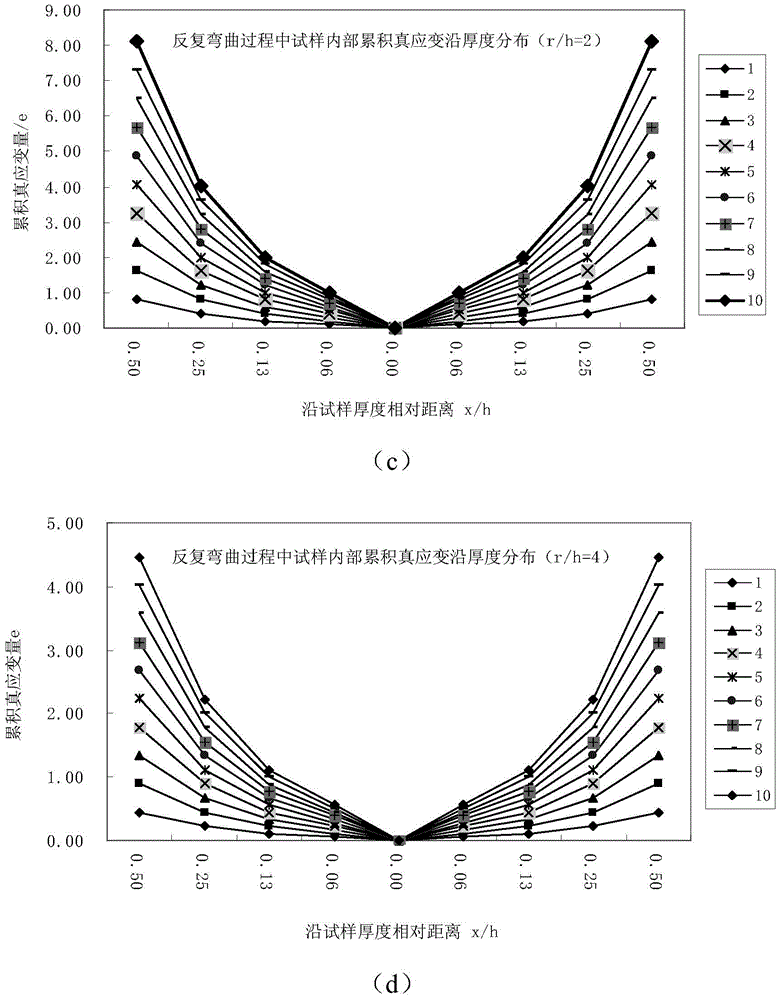

[0054] 1. Experimental analysis of the metallographic structure of the metal plate after bending deformation

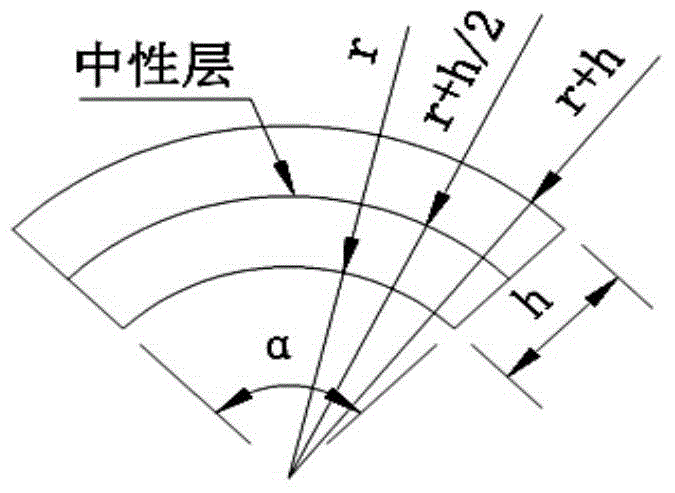

[0055] In order to further analyze the effect of the internal cumulative strain on the metal structure of the H85 brass plate after repeated plastic bending deformation. Sampling at different positions along the thickness direction of the sample (such as Figure 4 Shown, is the sampling position) for metallographic observation and analysis.

[0056] The metallographic samples taken are: fully annealed sample before bending deformation, 3 cycles of bending deformation with diameter-thickness ratio r / h=1.5, 5 cycles of bending deformation with diameter-thickness ratio r / h=4 Sample, the metallographic microstructure of the sample is as follows Figure 5 shown. From Figure 5 (a) It can be seen that the grains of the annealed material are mostly equiaxed, and the average grain size is about 60 μm. Figure 5 (b) is r / h=1.5, after 3 cycles of bending deformation, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com