Method for improving resistant property of heat resistant steel for high-temperature water vapour oxidation

A heat-resistant steel, water vapor technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

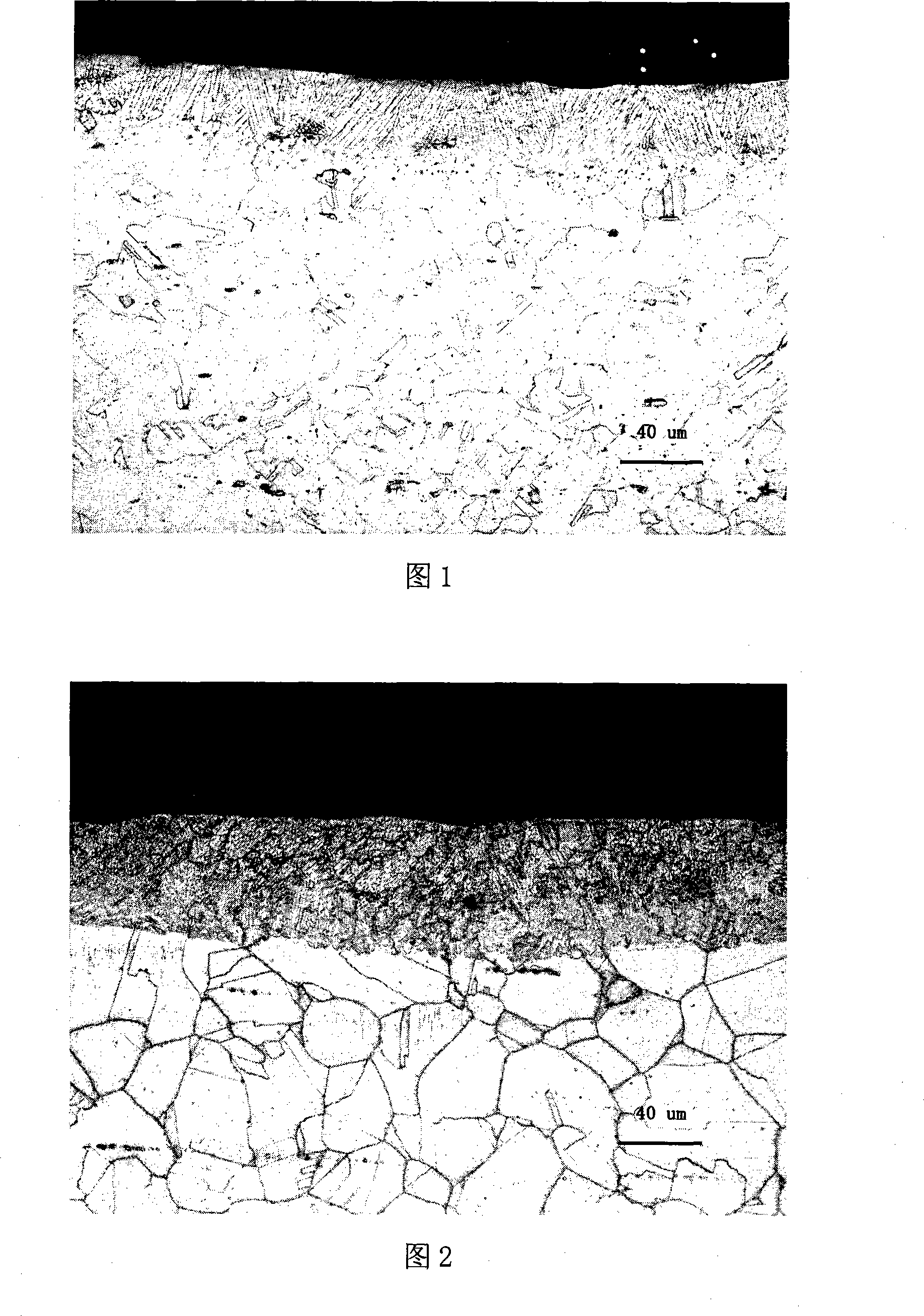

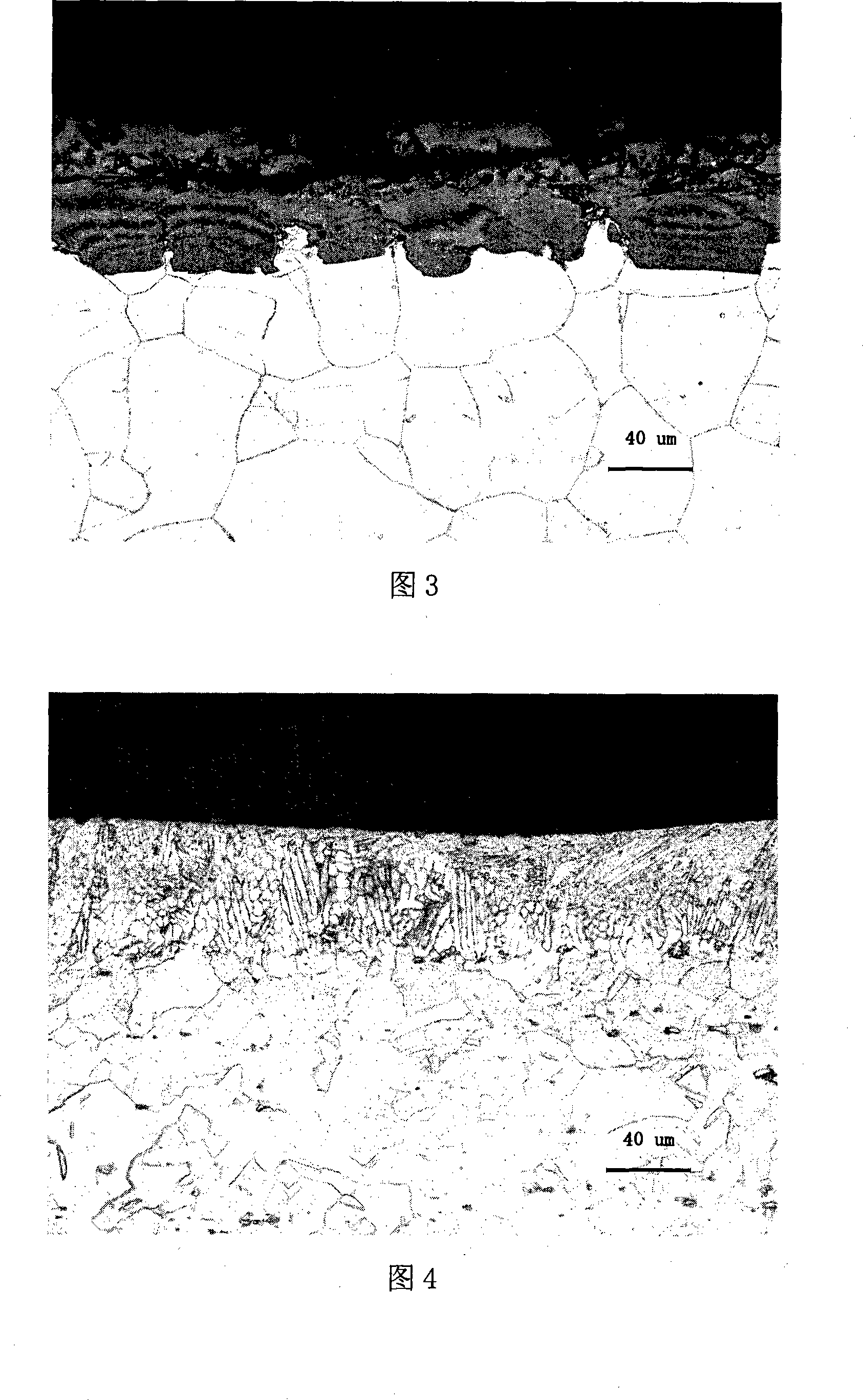

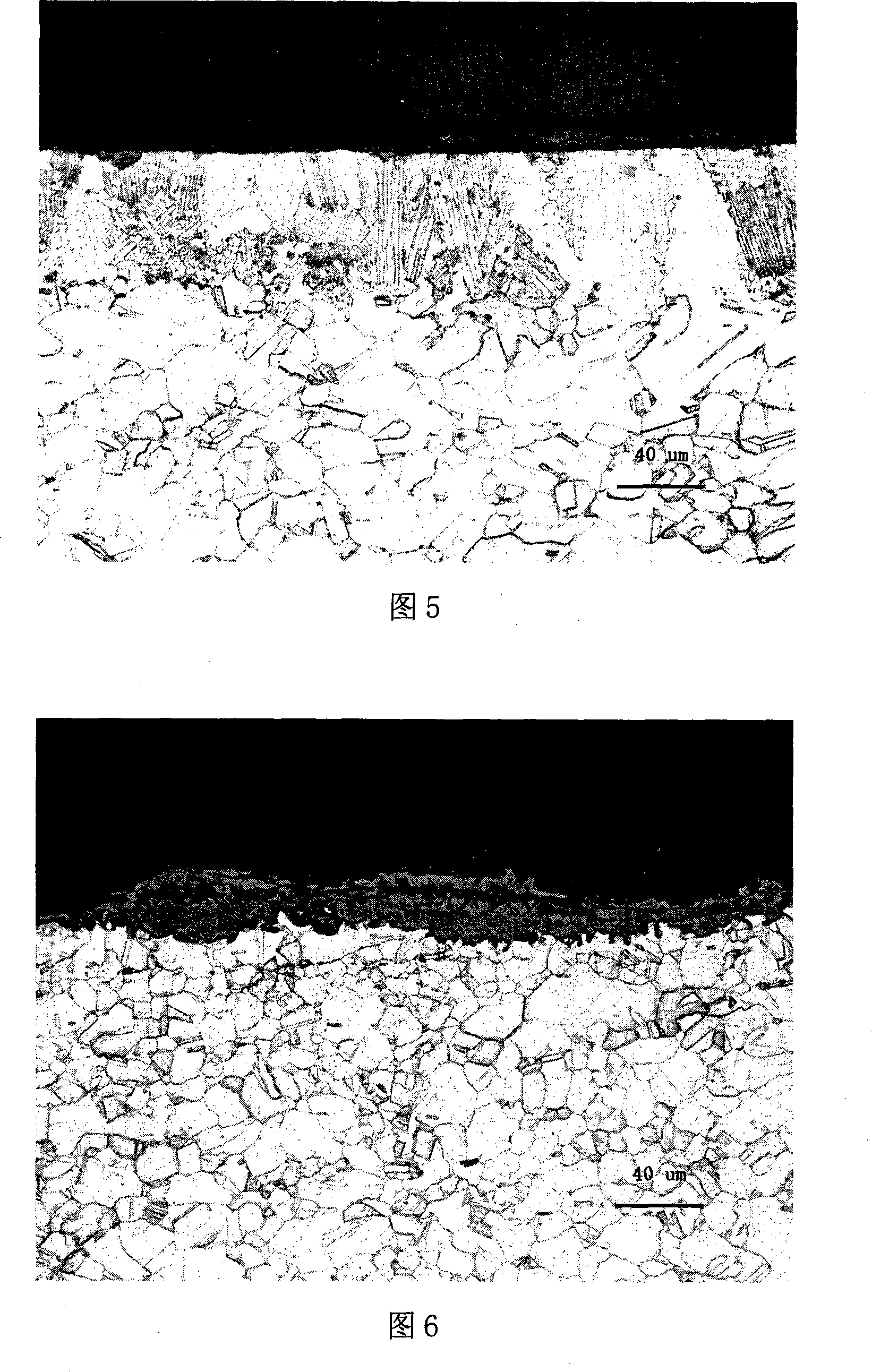

[0025] In the present invention, the surface of the heat-resistant steel to be treated is subjected to laser surface remelting treatment, so that the surface layer of the heat-resistant steel is 10 3 ~10 7 ℃ / s above the rate of heating and melting, and then 10 3 The cooling rate above ℃ / s solidifies, and a fine-grained region with a grain size below 25 μm is formed on the surface of the heat-resistant steel. The resistance to high temperature water vapor oxidation is improved through defects such as high-density grain boundaries, subgrain boundaries, dislocations, and vacancies of the treatment layer.

[0026] In order to further improve the steam oxidation resistance of the laser remelted layer on the heat-resistant steel surface, a coating containing Cr, Al or Si elements is formed on the heat-resistant steel surface by pretreatment before the laser surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com