Capillary eddy heat exchanger

A technology of heat exchanger and capillary tube, which is applied in the field of capillary vortex heat exchanger, can solve the problems of occupying branch tube space, shortening the life of equipment, and affecting the heat exchange effect, so as to enhance the heat exchange effect, avoid equipment damage, and improve equipment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

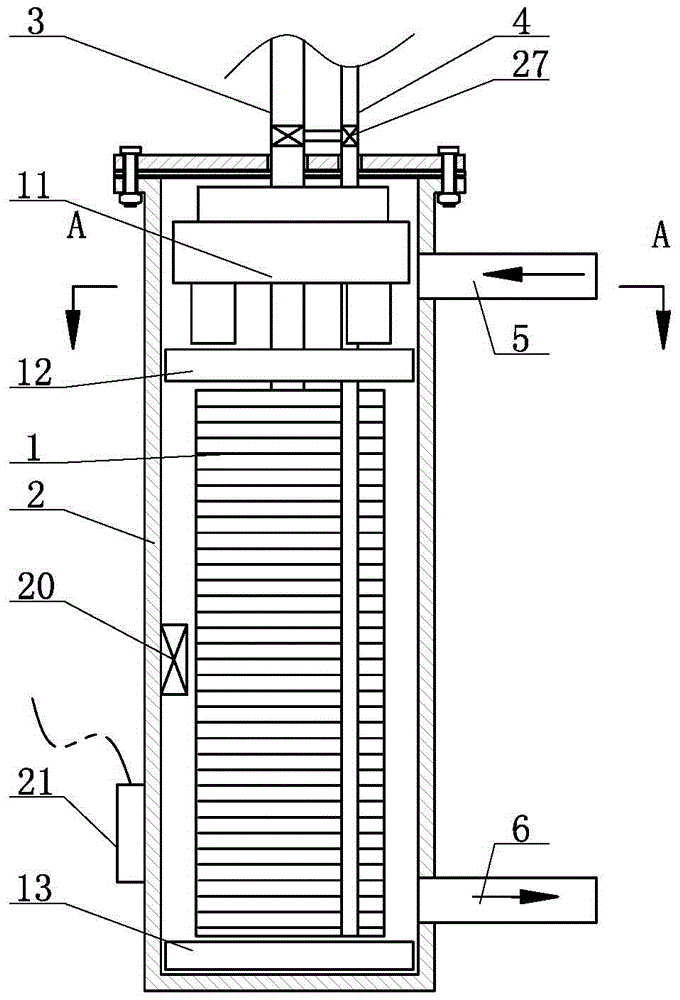

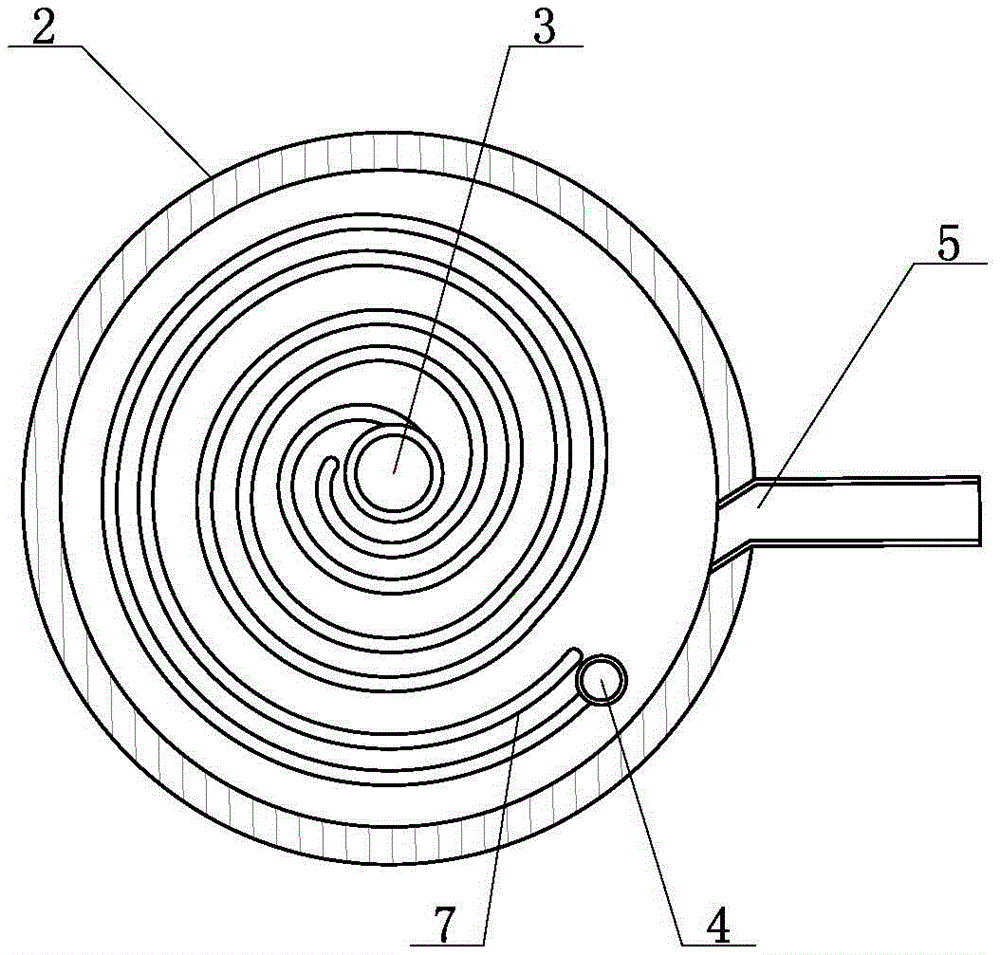

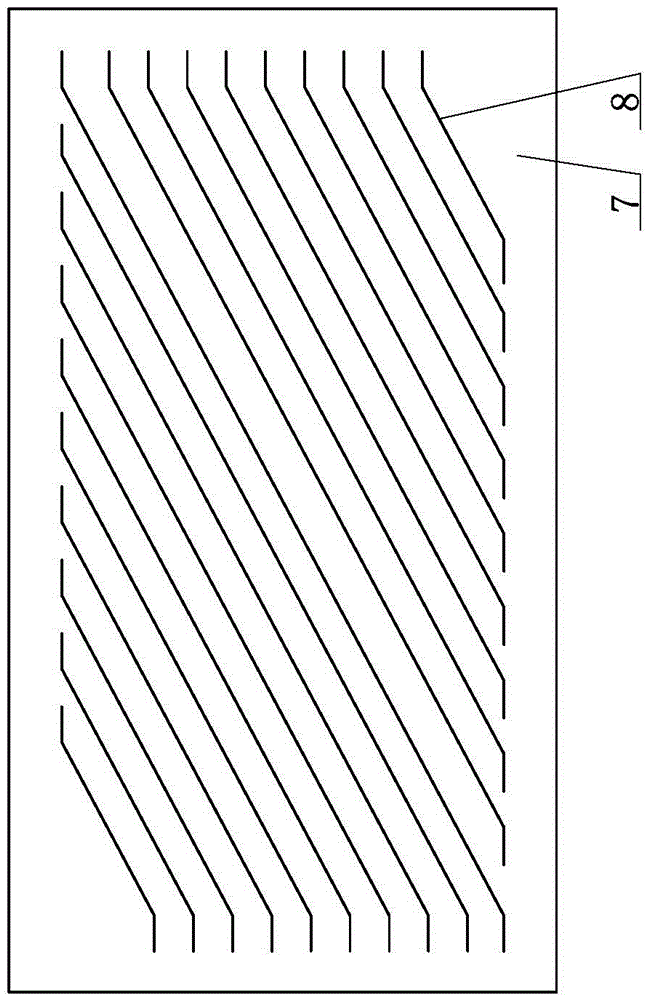

[0042] likefigure 1 and 2 As shown, a capillary vortex heat exchanger according to the present invention includes a casing 2, a cooling medium circulation pipeline is arranged in the casing 2, and water inlets 5 and The water outlet 6 and the water inlet 5 are located above the water outlet 6 . The cooling medium circulation pipeline includes an input pipe 3 and an output pipe 4, and several branch pipes 1 with both ends connected to the input pipe 3 and the output pipe 4 are arranged in parallel, and the branch pipe 1 is spirally wound around the input pipe 3 or the output pipe 4; The water inlet direction of the water port 5 and the casing 2 form an angle of 0-45 degrees. The rotation direction of the incoming water is opposite to the flow direction of the cooling medium. The water circulation is opposite to the cooling medium ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com