Magnesium alloy cellular board and manufacturing technique

A magnesium alloy and honeycomb panel technology, which is applied in the direction of metal layered products, layered products, transportation and packaging, etc., can solve the problems of magnesium alloy foils such as the difficulty of precise bending and forming, and achieve humanized transportation, improve ride conditions, Noise and vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now in conjunction with the magnesium alloy honeycomb panel production process schematic diagram, the present invention is further specifically described:

[0026] (1) Manufacture of honeycomb core structure 1: The magnesium alloy, such as AZ31B, is rolled into a foil with a thickness of 0.08-0.25mm by cold rolling or hot rolling. After heat treatment and surface treatment, its performance parameters are shown in Table 1. ; Cut the above foil material into foil strips with a width of 6-38mm, such as figure 1 shown;

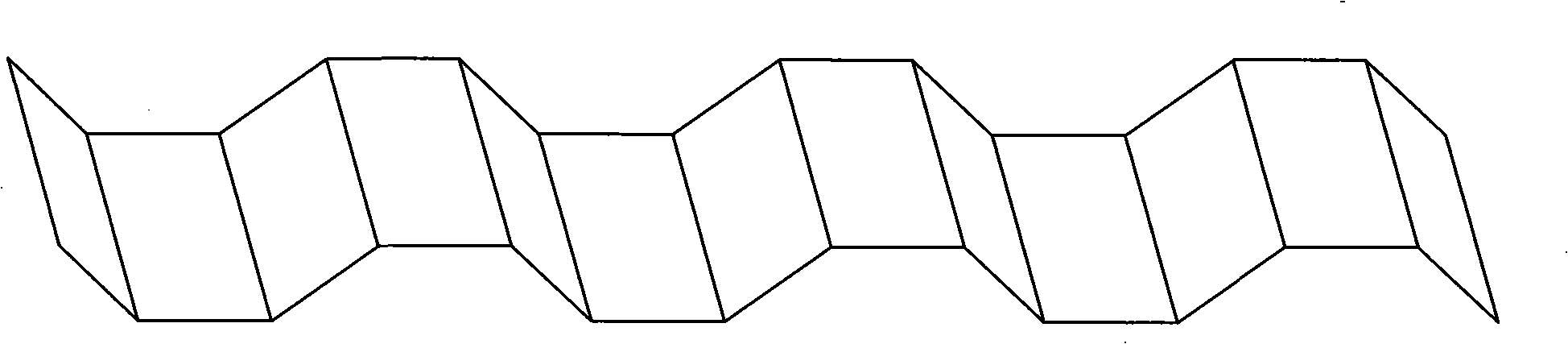

[0027] Then the above-mentioned foil strips are accurately and non-damagingly bent to form a honeycomb core blank, such as figure 2 As shown, the formed excessive fillet radius is 0.45mm, corresponding to it, the forming strain rate is 0.0015 / s;

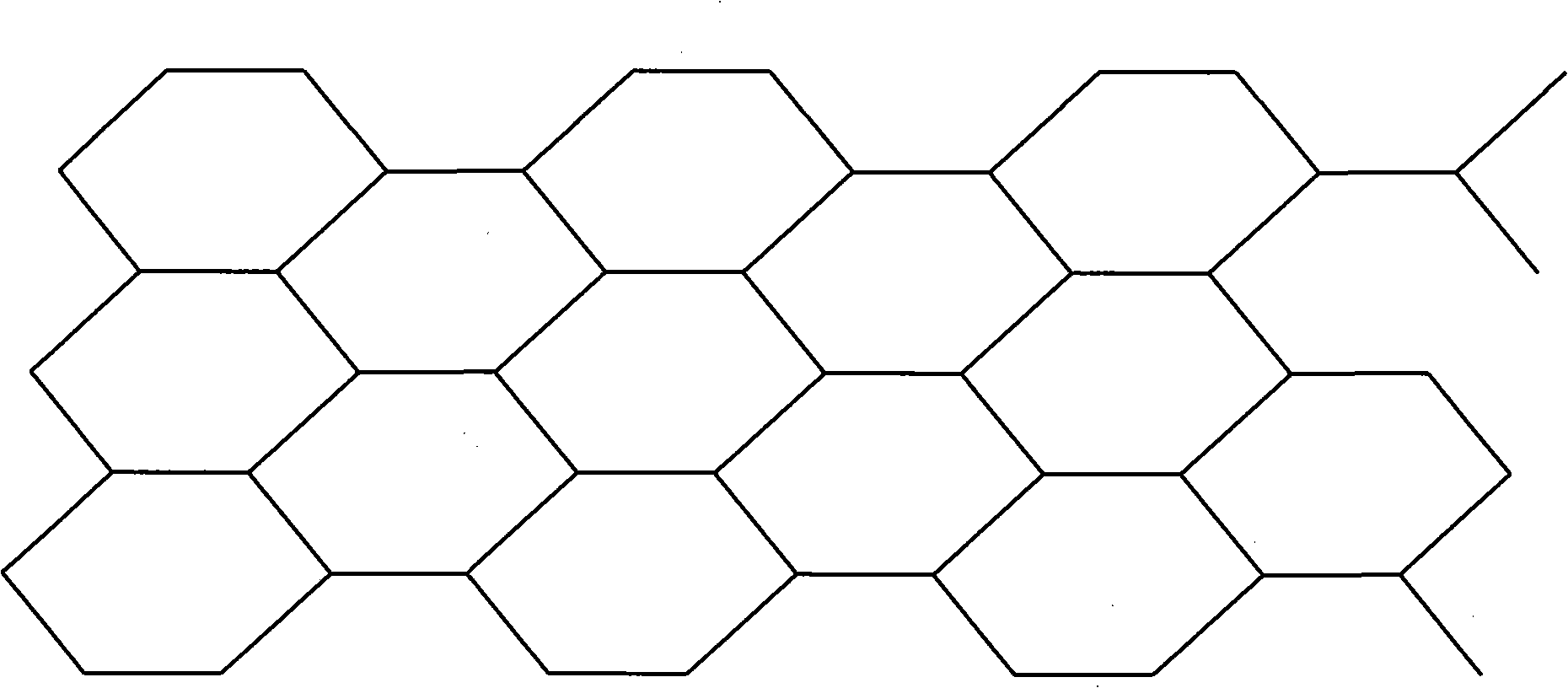

[0028] Place the formed honeycomb core blank on the working platform for gluing, positioning, and lamination, and then cure it at a specified temperature of 80-120°C and a specified pressure of 3-10MPa to make ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com