Bourdon tubular gauge

A Bourdon tube and pressure gauge technology, applied in the direction of elastic deformation gauge type fluid pressure measurement, etc., can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

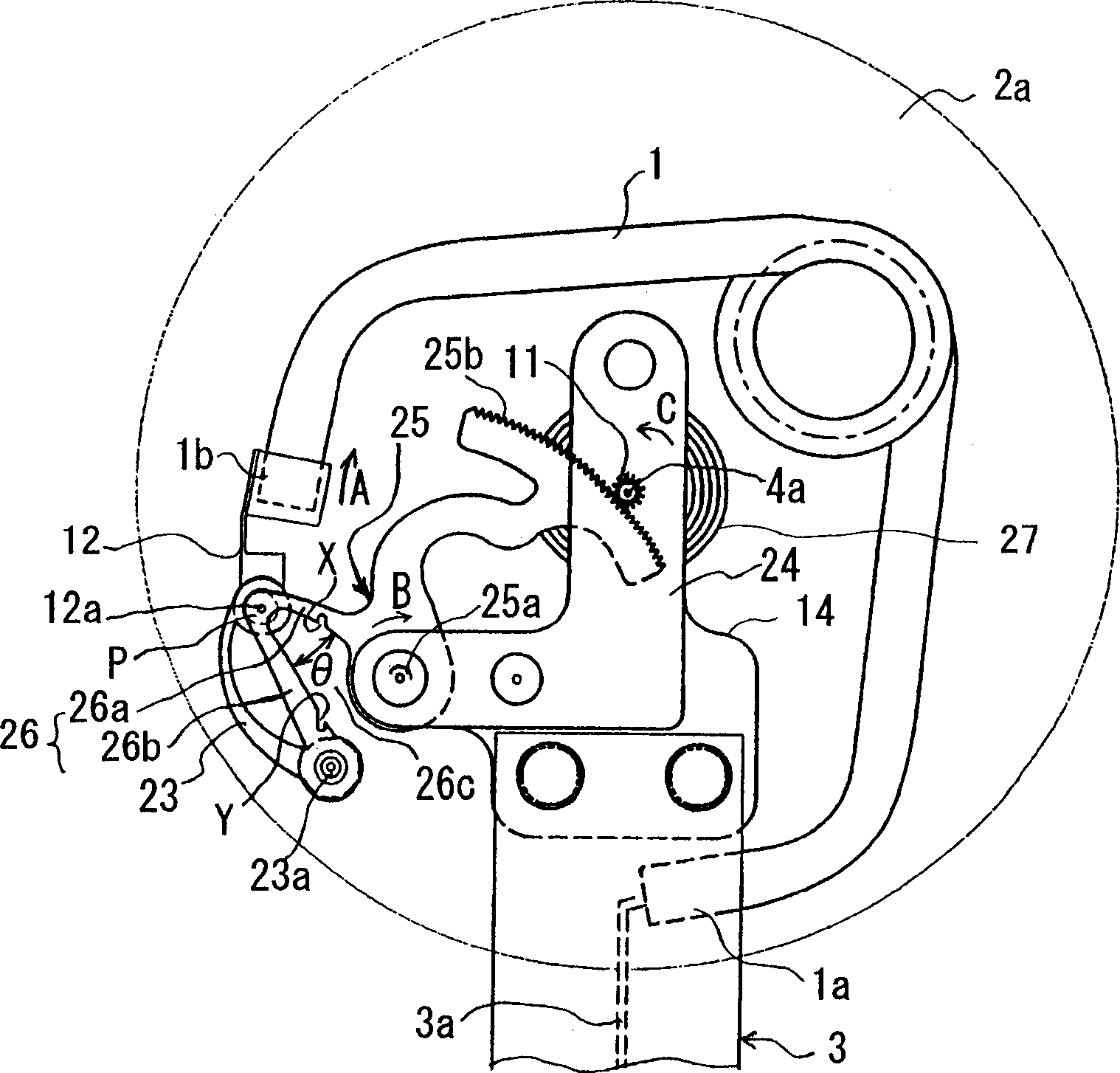

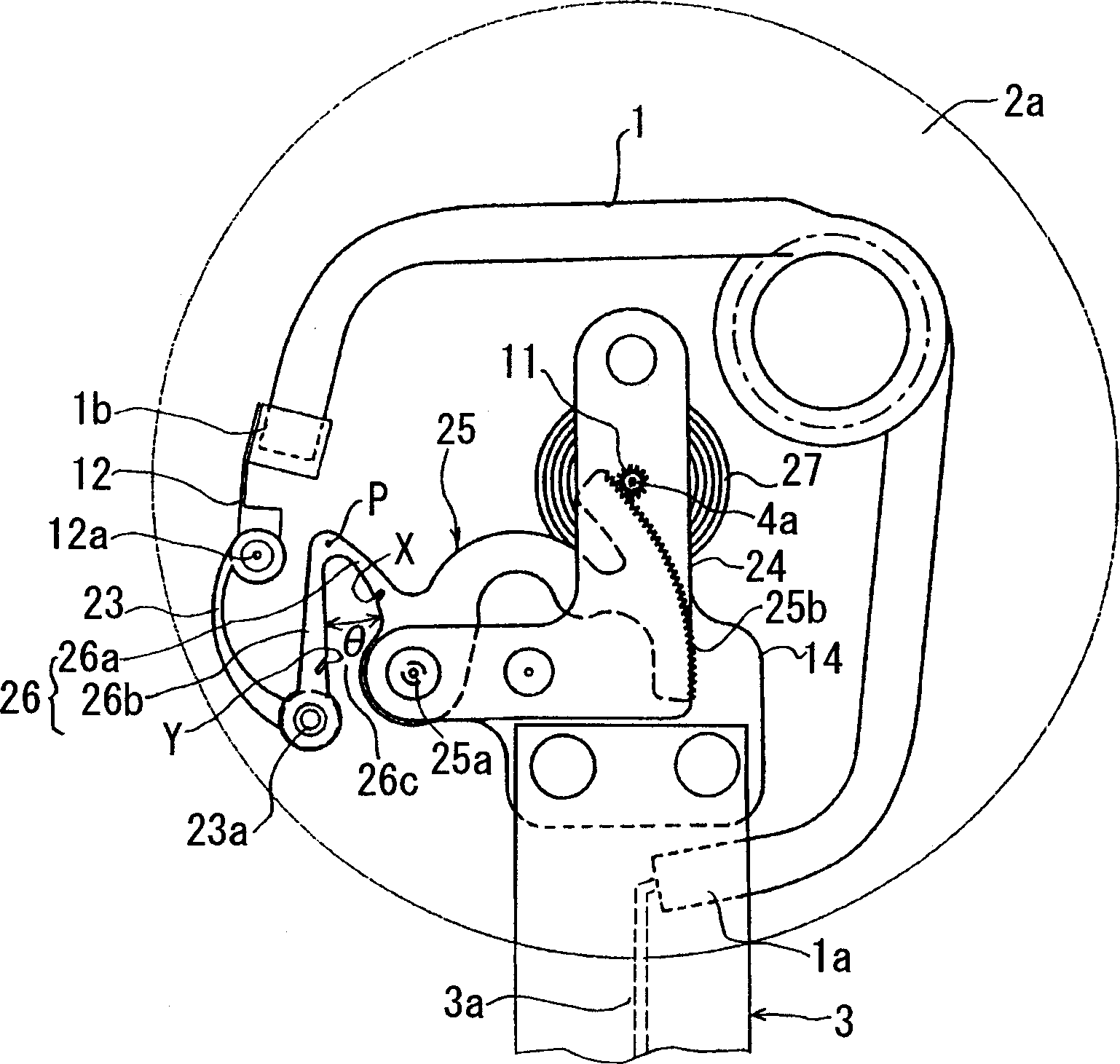

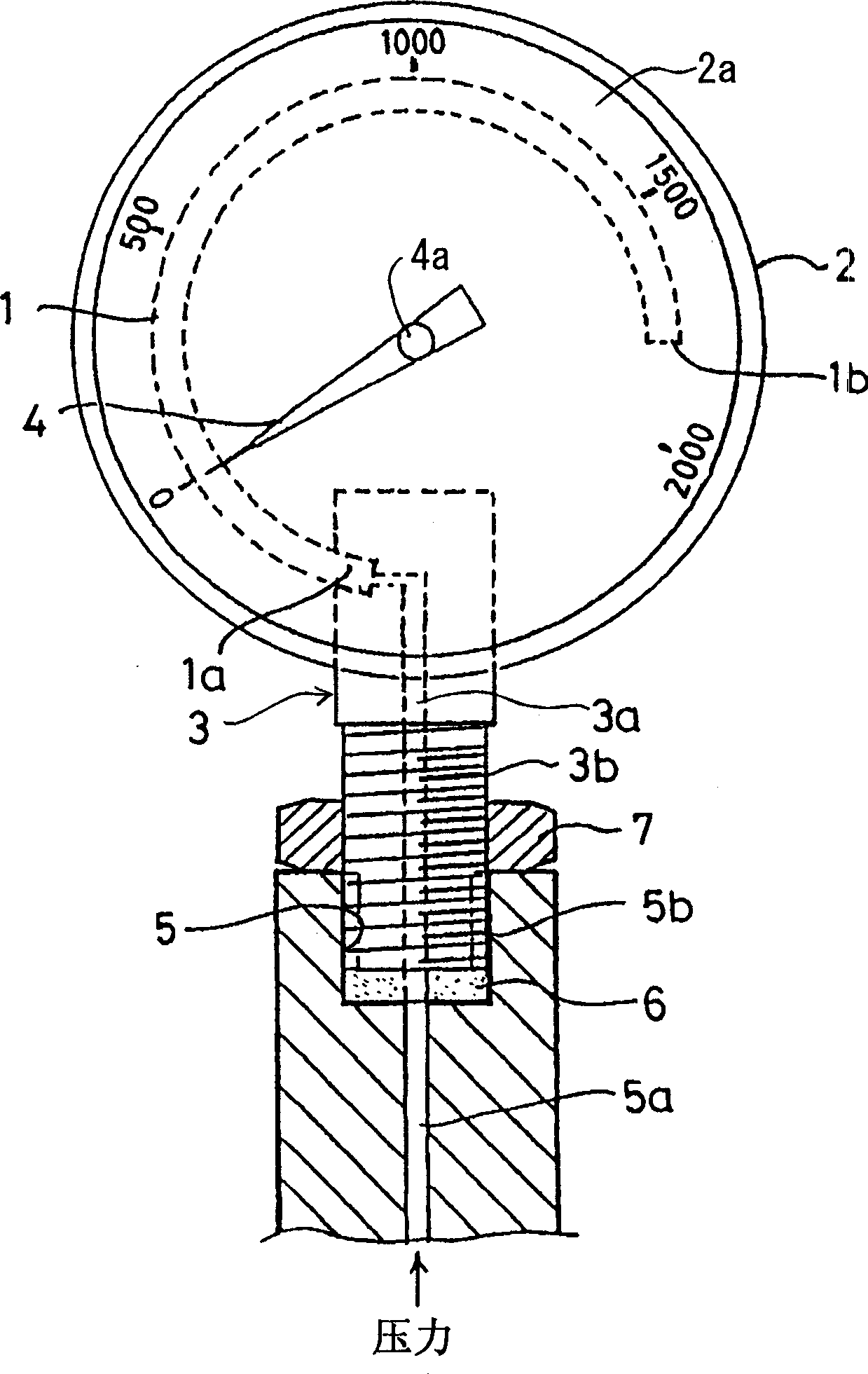

[0021] An embodiment of the present invention will be described below with reference to the accompanying drawings. figure 1 It is a rear view showing the displacement expansion link mechanism in the state where the maximum pressure is applied in the Bourdon tube pressure gauge related to the embodiment of the present invention, figure 2 It is a rear view showing the displacement expansion link mechanism in a pressureless state in the Bourdon tube pressure gauge related to the embodiment of the present invention. In addition, in figure 1 , 2 in, with Figure 4 The parts shown in are the same parts with reference symbols, and their explanations are omitted.

[0022] The displacement expansion link mechanism of this example has a Bourdon tube 1, a bow-shaped connecting rod 23, and a rotating plate (lever arm, sector) 25, and the Bourdon tube 1 moves around the pointer shaft 4a at the tube end 1b as the pressure increases. 3-way with respect to the pressure inlet pipe as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com