Equal-thickness in-plane continuous plate strip bending method

An internal bending, continuous plate technology, applied in metal rolling and other directions, can solve the problems of reduced material properties and low material utilization, and achieve the effects of improving mechanical properties, avoiding forming defects, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

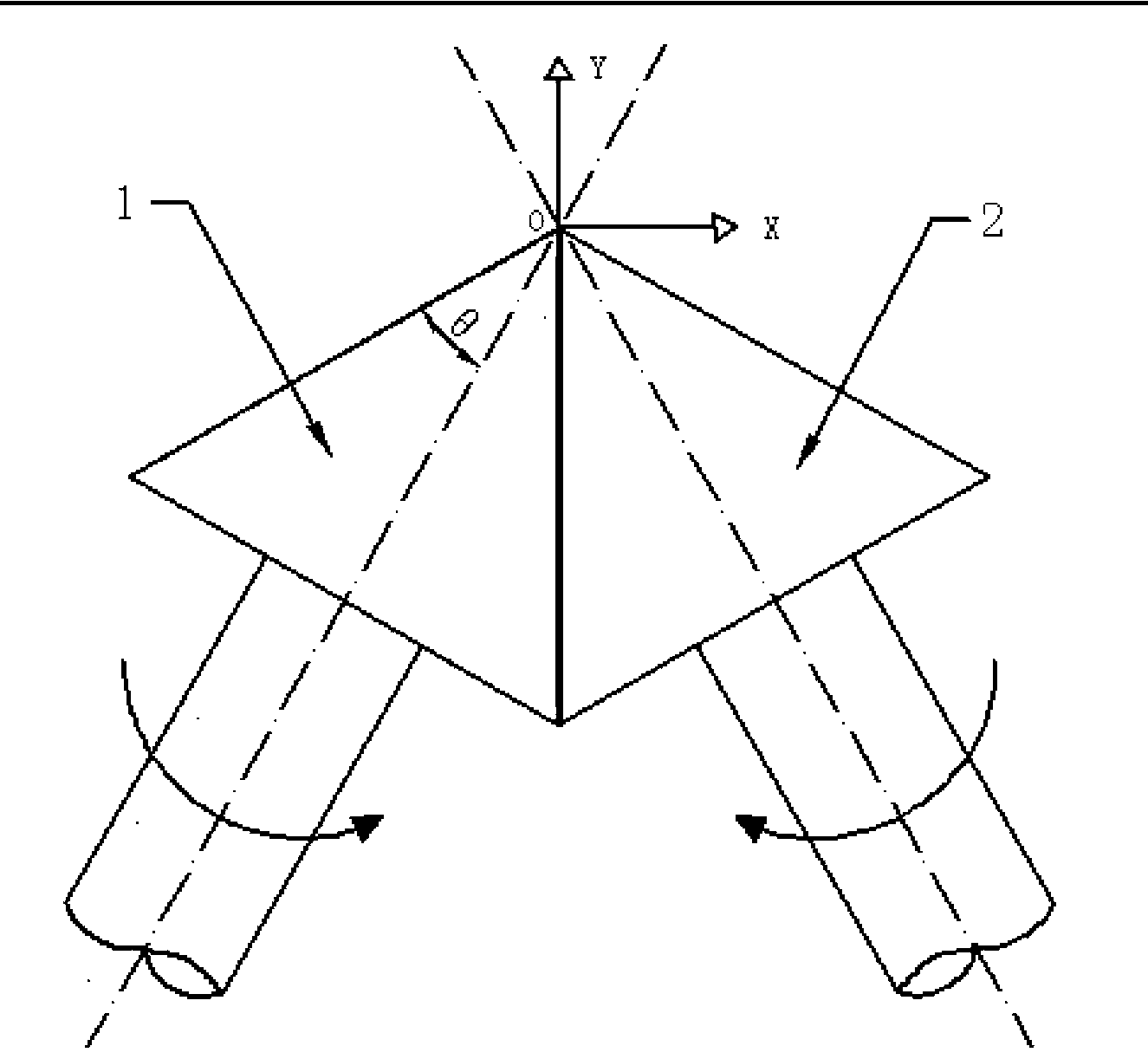

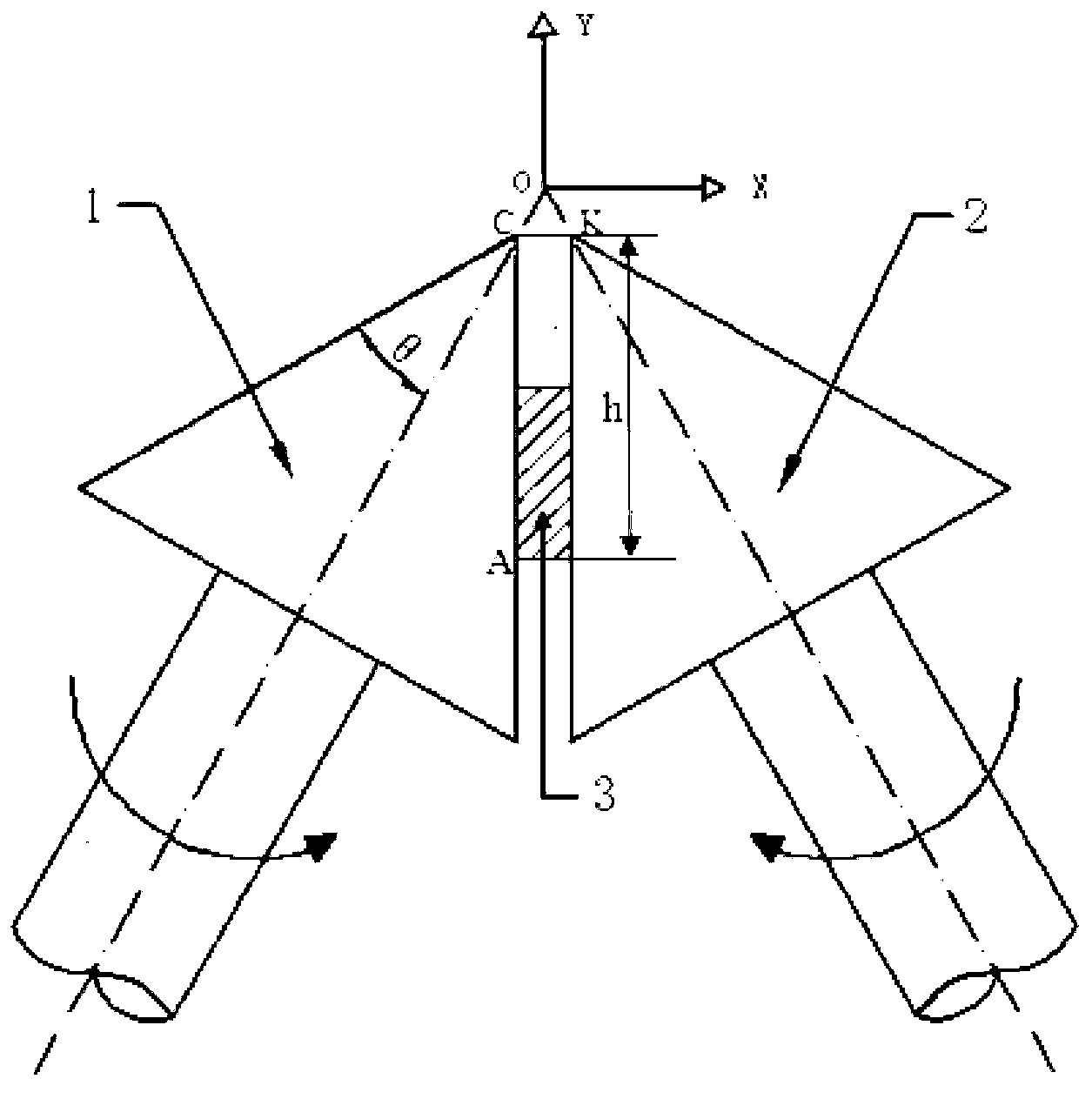

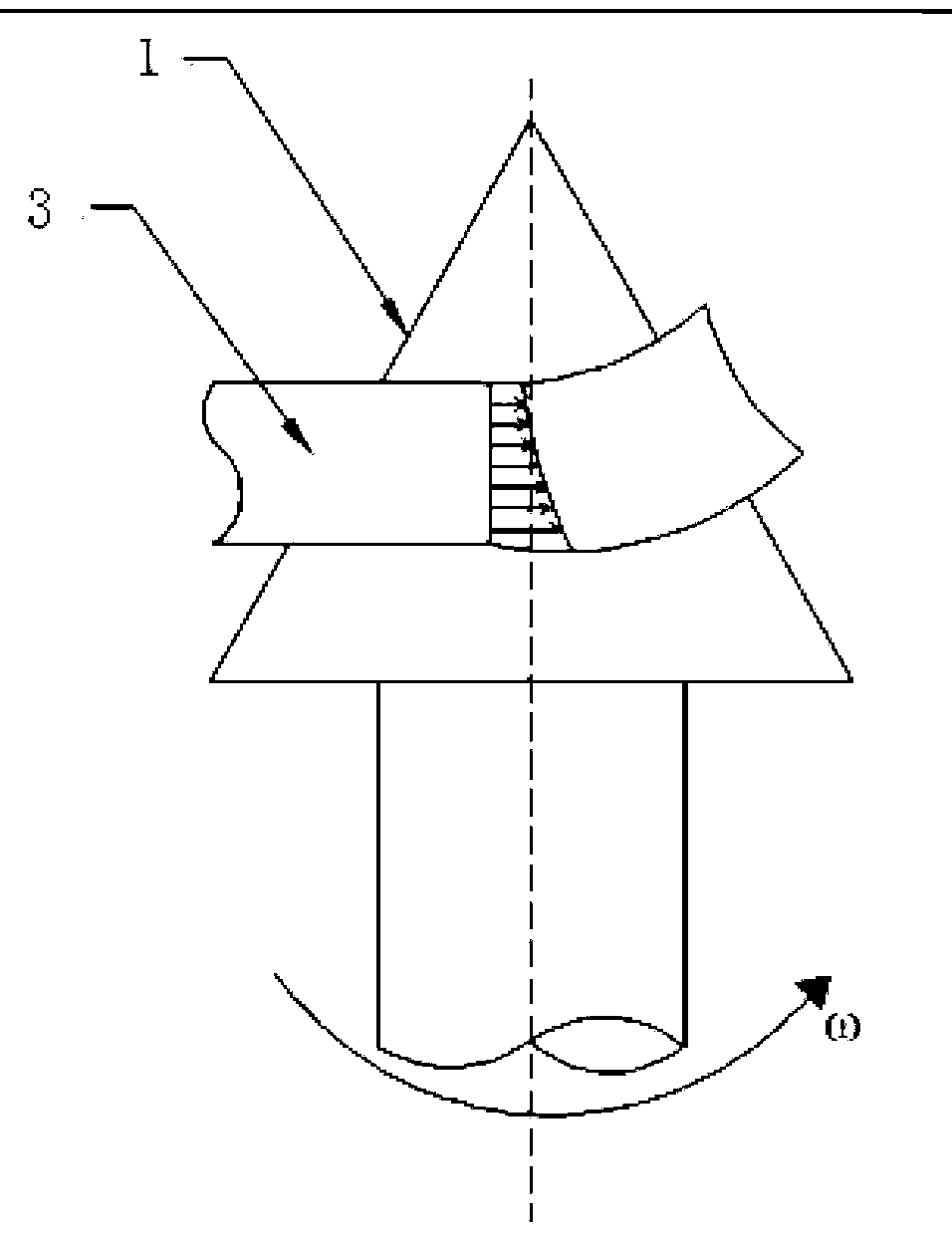

[0034] This embodiment is a method for continuously forming an in-plane bending ring piece with a thickness of the plate and strip realized on the roll adjustment mechanism of the in-plane bending forming device for the strip. The technical solution of the roll adjustment mechanism of the in-plane bending forming device for the strip is disclosed in the invention patent No. 200810231900.1. In this embodiment, the strip in-plane bending forming device includes a first roller and a second roller, and the two rollers are tapered rollers. The cone angles of the first roller and the second roller are α=60°, each Length of bus bar of roll l 0 =110mm. The first roll and the second roll are arranged symmetrically, and the angle between the axes of the two rolls is 60°. The thickness of the in-plane curved ring to be formed is t=1mm. The specific forming process is as follows:

[0035] Step 1. Prepare the sheet

[0036] According to the shape and size of the roll of the strip in-plane b...

Embodiment 2

[0055] This embodiment is a method for continuously forming an in-plane bending ring piece with a thickness of the plate and strip realized on the roll adjustment mechanism of the in-plane bending forming device for the strip. The technical solution of the roll adjustment mechanism of the in-plane bending forming device for the strip is disclosed in the invention patent No. 200810231900.1. In this embodiment, the strip in-plane bending forming device includes a first roller and a second roller, and the two rollers are tapered rollers. The cone angles of the first roller and the second roller are α=60°, each Length of bus bar of roll l 0 =110mm. The first roll and the second roll are arranged symmetrically, and the angle between the axes of the two rolls is 60°. The thickness of the in-plane curved ring piece to be formed is t=1.2mm. The specific forming process is as follows:

[0056] Step 1. Prepare the sheet

[0057] According to the shape and size of the roll of the strip in...

Embodiment 3

[0076] This embodiment is a method for continuously forming an in-plane bending ring piece with a thickness of the plate and strip realized on the roll adjustment mechanism of the in-plane bending forming device for the strip. The technical solution of the roll adjustment mechanism of the in-plane bending forming device for the strip is disclosed in the invention patent No. 200810231900.1. In this embodiment, the strip in-plane bending forming device includes a first roller and a second roller, and the two rollers are tapered rollers. The cone angles of the first roller and the second roller are α=60°, each Length of bus bar of roll l 0 =110mm. The first roll and the second roll are arranged symmetrically, and the angle between the axes of the two rolls is 60°. The thickness of the in-plane curved ring piece to be formed is t=1.4mm. The specific forming process is as follows:

[0077] Step 1. Prepare the sheet

[0078] According to the shape and size of the rolls of the strip i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com