Forming device and method through uneven stretching and in-plane bending of aluminum alloy plate

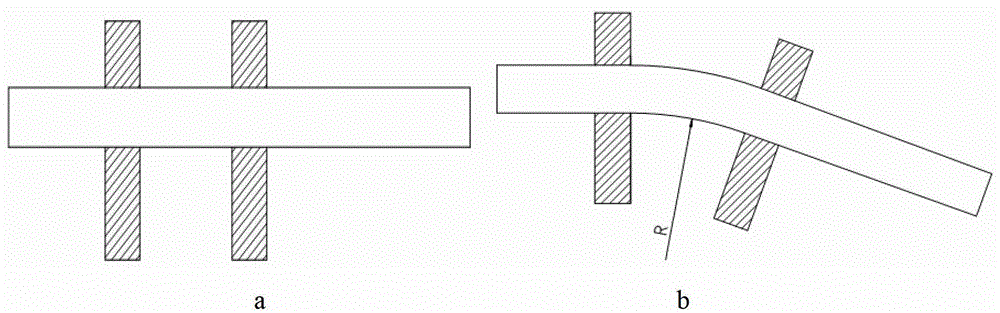

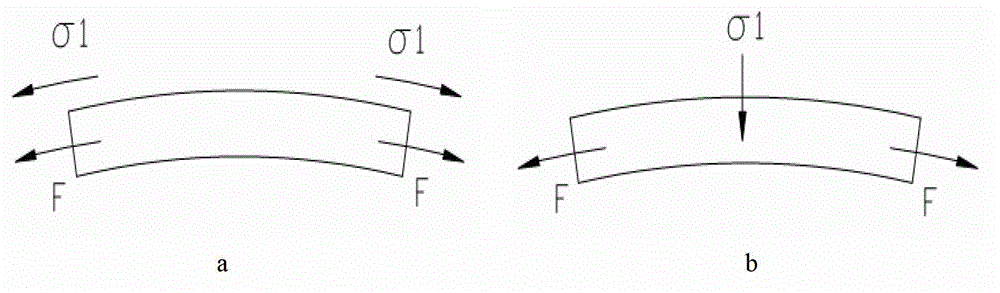

An aluminum alloy plate, bending forming technology, applied in the direction of metal rolling, etc., can solve the problems of outer edge wrinkling, poor fluidity, space distortion and inner edge wrinkling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

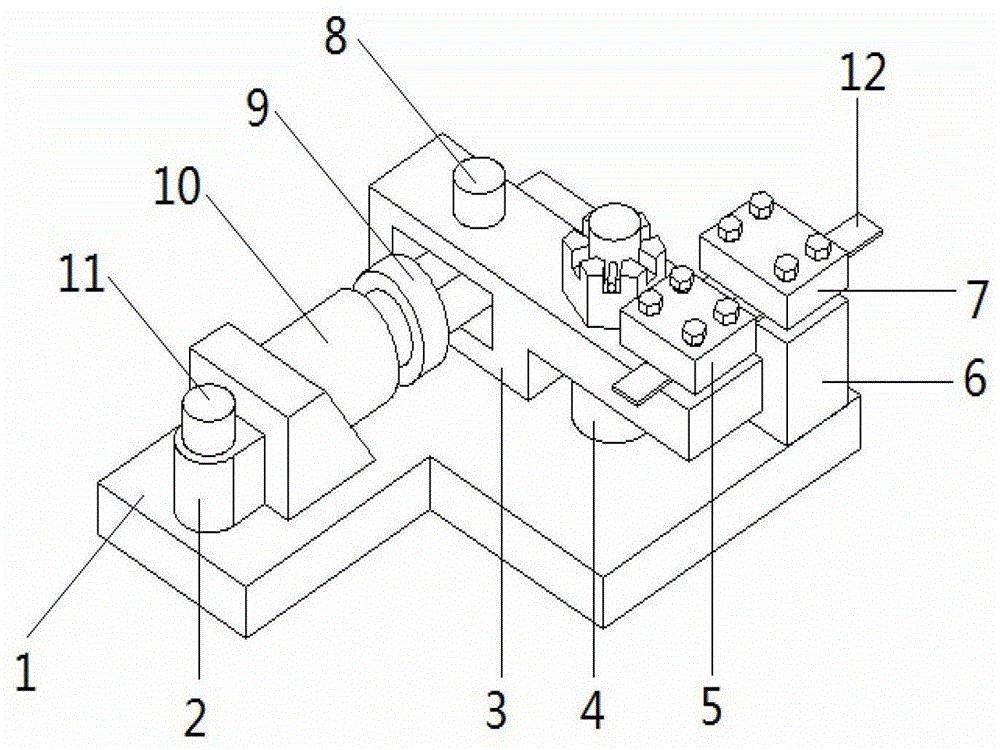

[0038] This embodiment is a device for in-plane bending forming of an aluminum alloy sheet with a length of 400 mm, a width of 20 mm, and a thickness of 2 mm, including a base 1 of the forming device, a pump frame 2, a rotating arm 3, a rotating shaft 4, and a first clamping block 5. Moving block 6, second clamping block 7, hydraulic cylinder 9 and hydraulic pump 10.

[0039] The hydraulic pump 10 is installed on the upper surface of the base 1, and the output shaft of the hydraulic pump 10 is fitted with a hydraulic cylinder 9. The other end of the hydraulic cylinder 9 is located in the square through hole of the rotating arm 3, and is rotated The arm pin 8 is fixed. The bottom end of the hydraulic pump 10 is fixed on the base 1 through the pump frame 2 . The rotating shaft 4 is fixed on the upper surface of the base 1 . The rotating arm 3 is installed on the rotating shaft 4, and the lower surface of the rotating arm 3 and the positioning surface of the rotating shaft are ...

Embodiment 2

[0049] This embodiment uses the in-plane bending forming device for the aluminum alloy sheet described in Embodiment 1 to bend the aluminum alloy sheet.

[0050] The aluminum alloy sheet has a length of 400mm, a width of 20mm, and a thickness of 2mm, and the bending angle is 60°. From the perspective of forming effect, the angle of each bending should not be too large. The maximum angle of one bending of the in-plane bending forming device of the aluminum alloy sheet described in this embodiment is 30°, so two bending formings are required. The specific process is:

[0051] In the first step, the aluminum alloy sheet to be formed is clamped on the first clamping block 5 and the second clamping block 7 and fastened.

[0052] The second step is to start the hydraulic pump for the first bending and stretching. Under the thrust of the hydraulic pump, the rotating arm is rotated to stretch the sheet. The rotation angle of the rotation arm is set according to the bending angle θ o...

Embodiment 3

[0062] This embodiment uses the in-plane bending forming device for the aluminum alloy sheet described in Embodiment 1 to bend the aluminum alloy sheet.

[0063] The aluminum alloy sheet has a length of 400mm, a width of 20mm, and a thickness of 2mm, and the bending angle is 50°. From the perspective of forming effect, the angle of each bending should not be too large. The maximum angle of one bending of the in-plane bending forming device for the aluminum alloy sheet described in this embodiment is 30°, so it is necessary to divide the bending into two times, wherein the first The first bending angle is 30°, and the second bending angle is 20°. The specific process is:

[0064] In the first step, the aluminum alloy sheet to be formed is clamped on the first clamping block 5 and the second clamping block 7 and fastened.

[0065] The second step is to start the hydraulic pump for the first bending and stretching. Under the thrust of the hydraulic pump, the rotating arm is ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com