A kind of smoldering furnace and smoldering system

A smoldering furnace and furnace body technology, applied in the field of combustion equipment, can solve the problems of low durability, low gasification efficiency, complex structure, etc., and achieve the effects of increasing the contact area, improving the combustion efficiency, and simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

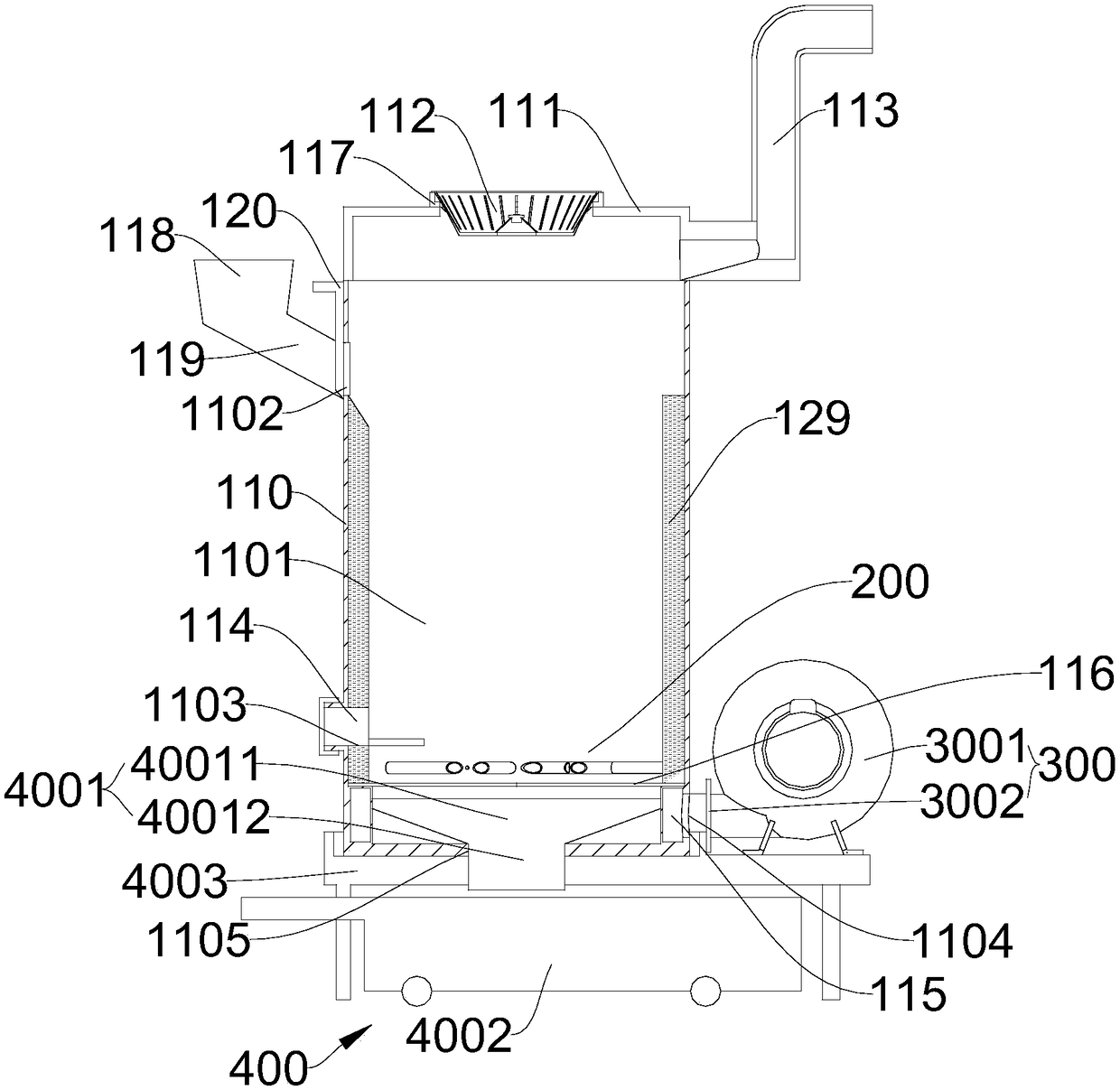

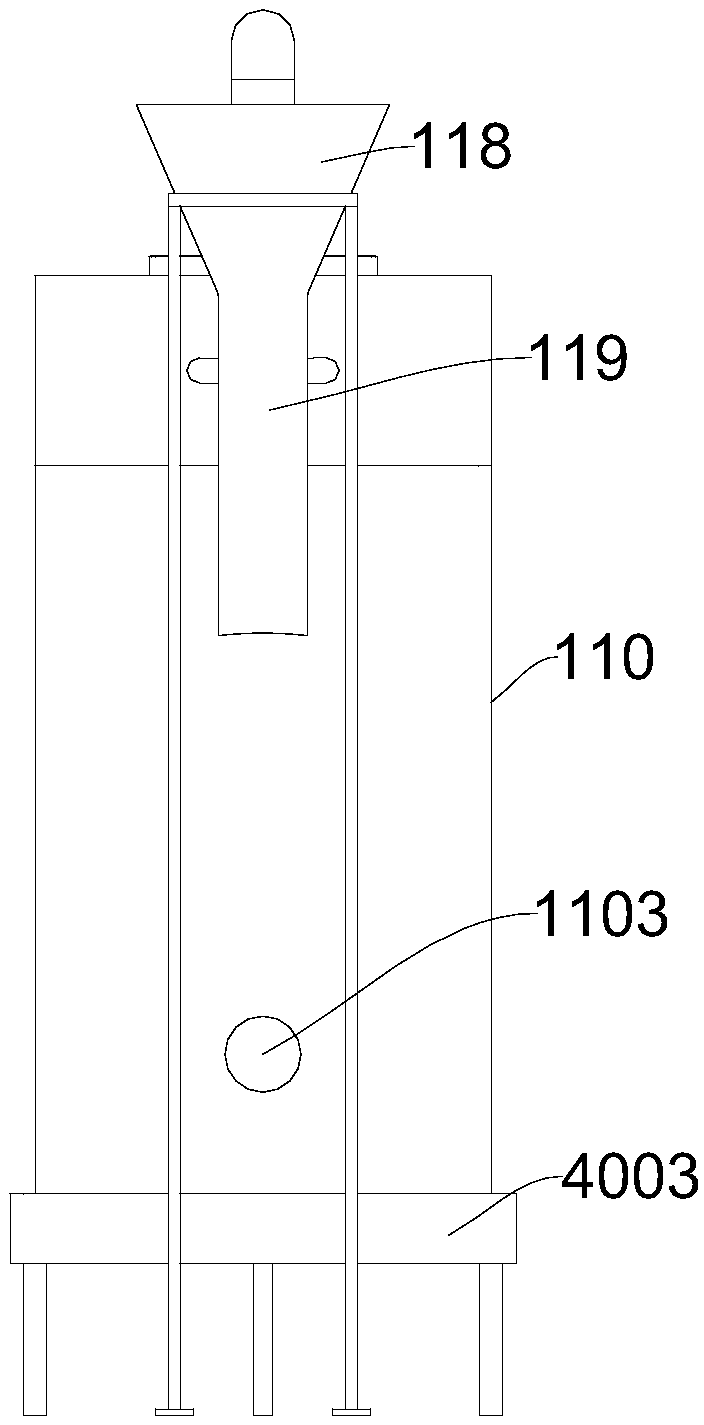

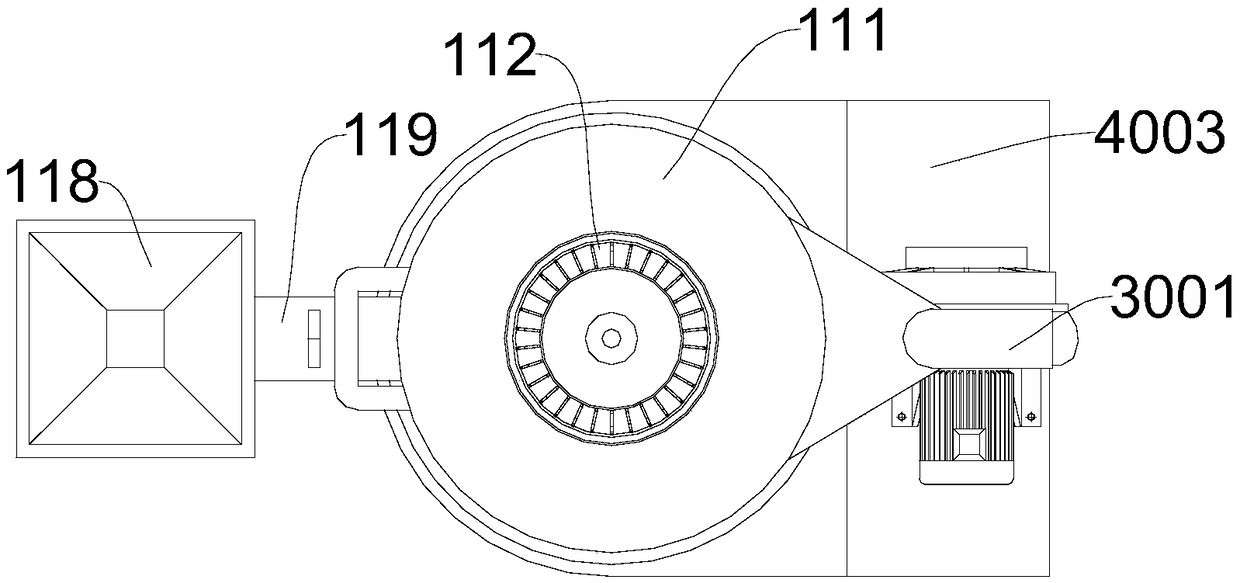

[0040] Embodiment 1, with reference to figure 1 , a smoldering furnace, comprising a furnace body 110 and an upper cover 111, the furnace body 110 is provided with a cavity 1101 with an open top, the upper cover 111 is detachably arranged on the top of the furnace body 110 and seals the cavity 1101, the upper cover 111 An installation port is provided with a stove head 112; the top of the side wall of the body of furnace 110 is provided with a feed port 1102 and a chimney 113, and the bottom end of the side wall of the body of furnace 110 is provided with an ignition port 1103 and an air inlet 1104. The bottom wall of 110 is provided with ash outlet 1105; ignition port 1103 is provided with igniter 114, and igniter 114 comprises kerosene nozzle and electronic igniter 114, and air inlet 1104 is provided with air inlet pipe 115; Cavity 1101 is provided with grate 116 and The air supply mechanism 200 , the air supply mechanism 200 is provided with a plurality of air supply openin...

Embodiment 2

[0063] Embodiment 2, a smoldering system, including a feeding device and a smoldering furnace, the feeding device includes a storage bin and a delivery pipeline, one end of the delivery pipeline communicates with the storage bin, and the other end of the delivery pipeline communicates with the feed port 1102 . The smoldering system only needs to store the fuel in the storage bin in advance, and then it can automatically complete the transportation and combustion, and the operation is convenient and quick.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com