Multi-station integrated environment glass fiber reinforced plastic bending creep test apparatus and method

A technology of bending creep and testing equipment, which is applied in the direction of applying stable bending force to test the strength of materials, measuring equipment, instruments, etc., can solve the problems of poor batch test feasibility and uncontrollable test environment, and save time, cost, and equipment The effect of simple structure and low economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

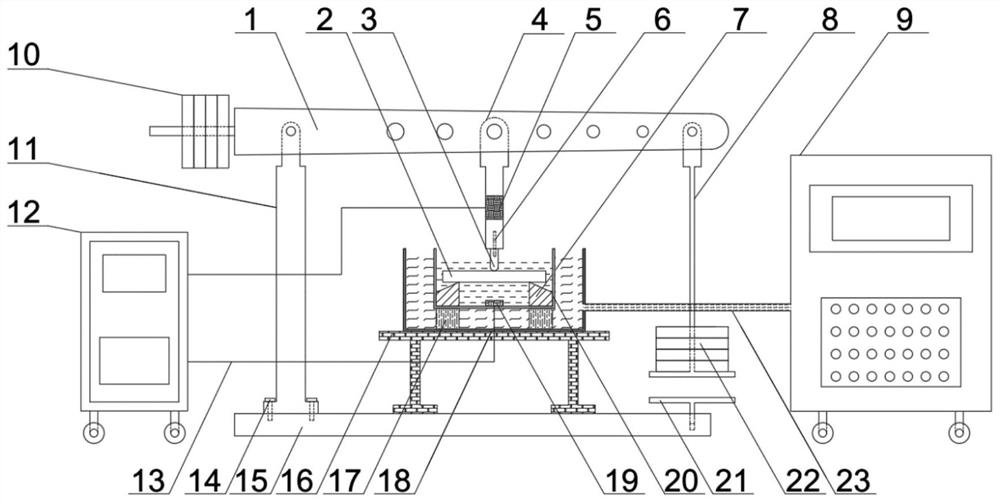

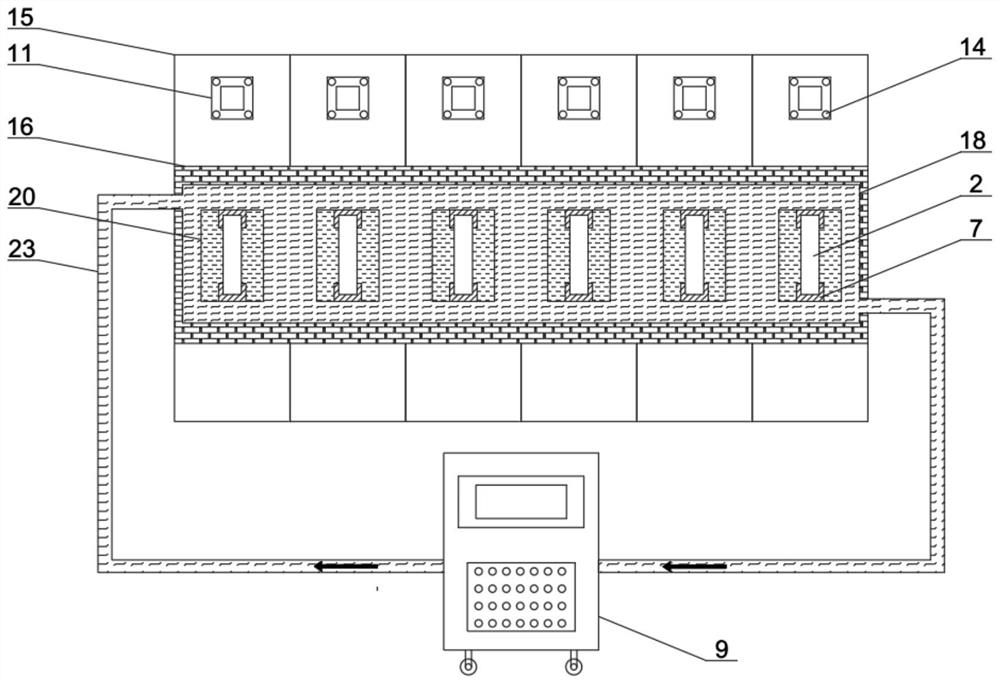

[0031] Such as figure 1 with figure 2 As shown, a multi-station integrated environmental FRP bending creep test device includes a lever loading device, a temperature control device and a data acquisition device.

[0032] The lever device is made up of support platform 16, base 15, pillar 11, beam 1, pressure bar 4, pressure head 3, weight plate 8, adjustable weight support plate 21, balance weight 10 and loading weight 22, base 15 Set on the support platform 16, the base 15 is provided with a vertical pillar 11, and the base 1 and the pillar 11 are fastened and connected by bolts 14, the top of the pillar 11 is provided with a horizontal beam 1, and the beam 1 is provided with a pressure bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com