Self-balancing type true three-dimensional loading model testing bench frame with sliding wall

A self-balancing, three-dimensional loading technology, applied in the direction of instruments, measuring forces, measuring devices, etc., can solve the problems of not reducing the friction force very much, the model depth is large, and the friction coefficient is high, so as to avoid adverse effects and impact resistance Good toughness and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

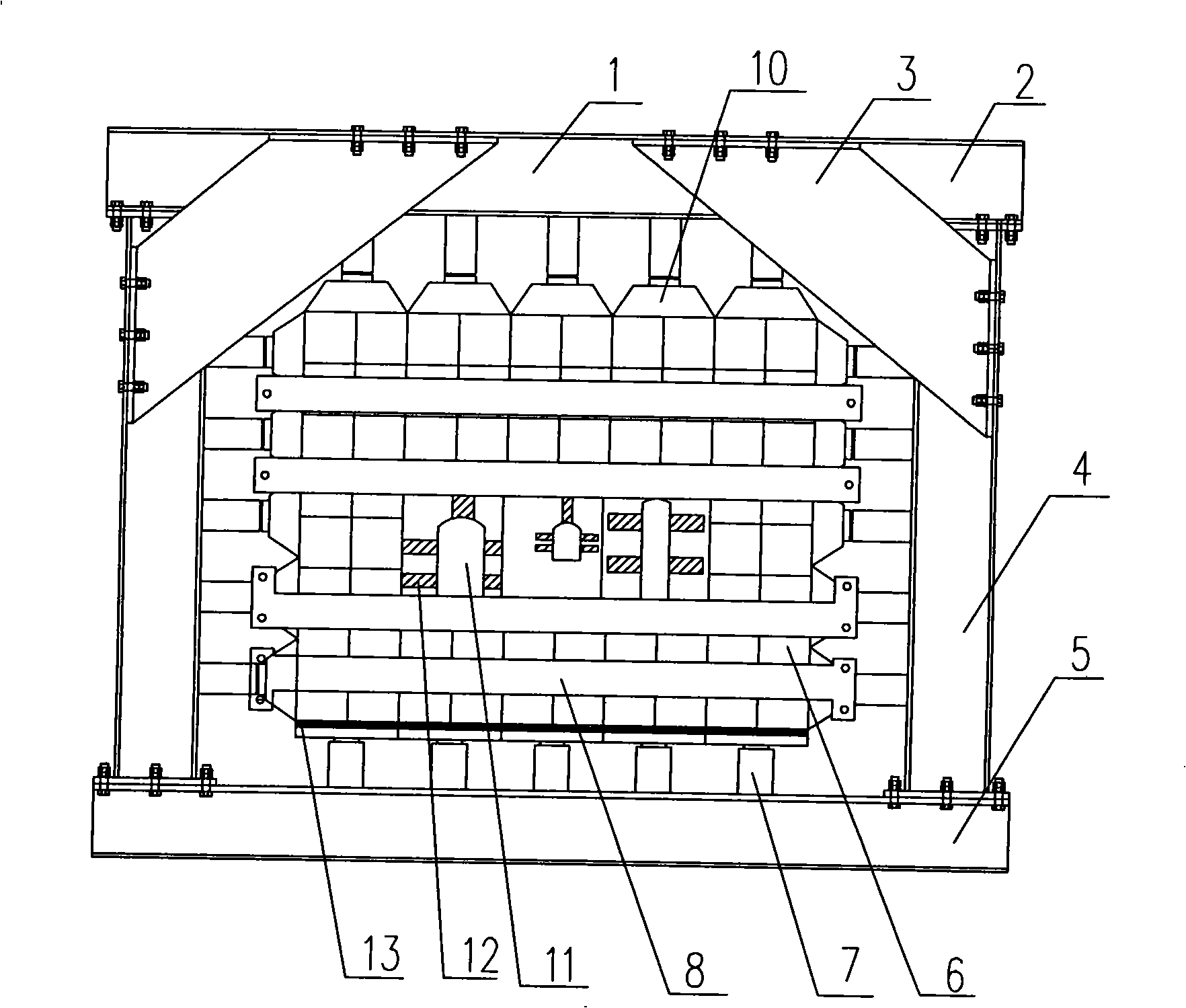

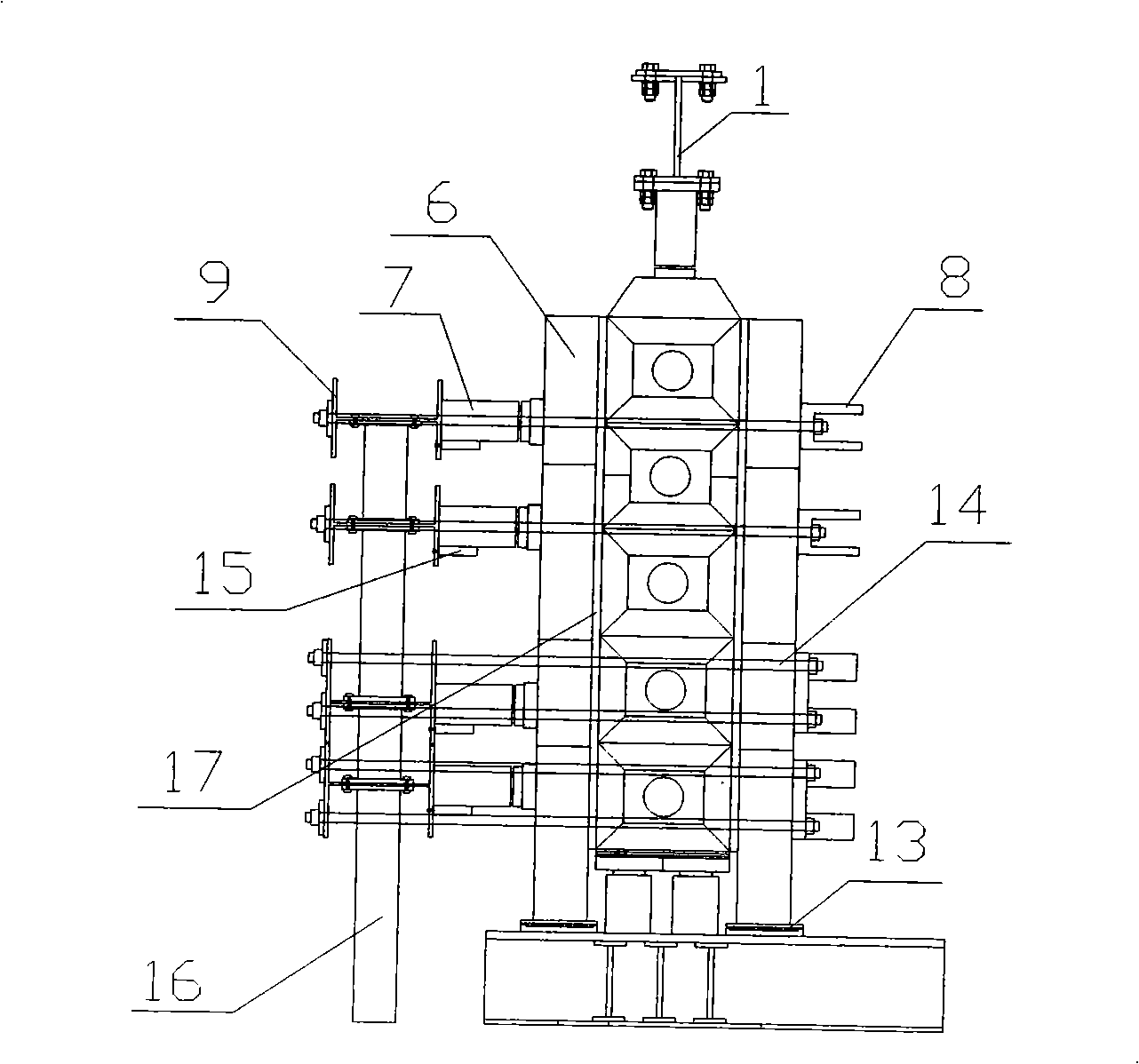

[0057] Figure 1-Figure 5 Among them, the sliding wall 17 is arranged on the outside of the model body, wherein, the upper, lower, left, and right sides of the sliding wall 17 are respectively provided with pressure-bearing plates 10, the front and rear sides of the sliding wall 17 are respectively provided with structural walls 6, and the outside of the pressure-bearing plate 10 and The outside of the structural wall 6 behind the sliding wall 17 is equipped with a hydraulic loading device, and the other end of the hydraulic loading device outside the pressure plate 10 is fixed on the door-type reaction frame 1; A front beam 8 and a rear beam 9 are respectively provided, and the front beam 8 and the rear beam 9 are connected by a tie rod 14, and the rear beam 9 is arranged on a support frame 16 on the ground; around the position of the cavern 11 on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com