Manufacturing technology for preparing high-strength bamboo-plastic composite material through MAPE pretreatment

A composite material and preparation technology, which is applied in the field of preparation of MAPE compatibilizer pretreatment to enhance the degree of bonding, can solve problems such as interface compatibility and coupling agent dosage, and achieve equipment loss reduction, efficient utilization, and elimination of effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

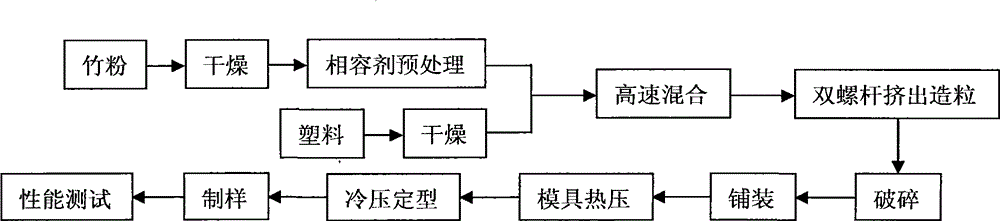

Method used

Image

Examples

Embodiment Construction

[0019] (1) Raw material pretreatment

[0020] Drying: Bamboo powder and plastic need to be dried before extruding and granulating. This is because during the granulation process, if the bamboo powder contains more water and extracts, water vapor and volatile gas will be generated on the surface of the bamboo powder, which will not only reduce the adhesion between the bamboo powder and the plastic interface, but also Pores will be created in the plastic matrix.

[0021] Put the bamboo powder in an electric blast drying box and dry it at 105°C for 8 hours to remove moisture and extracts, and adjust the moisture content to below 3%.

[0022] MAPE pretreatment bamboo powder: The weighed MAPE compatibilizer is directly blended with the dried bamboo powder in a high-speed mixer for 20 minutes to make the grafting reaction proceed fully.

[0023] (2) Mixing

[0024] The high-speed mixer is suitable for mixing solid-solid and solid-liquid materials, and is also commonly used for powder prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com