Environment-friendly bio-oil starch adhesive and preparation method thereof

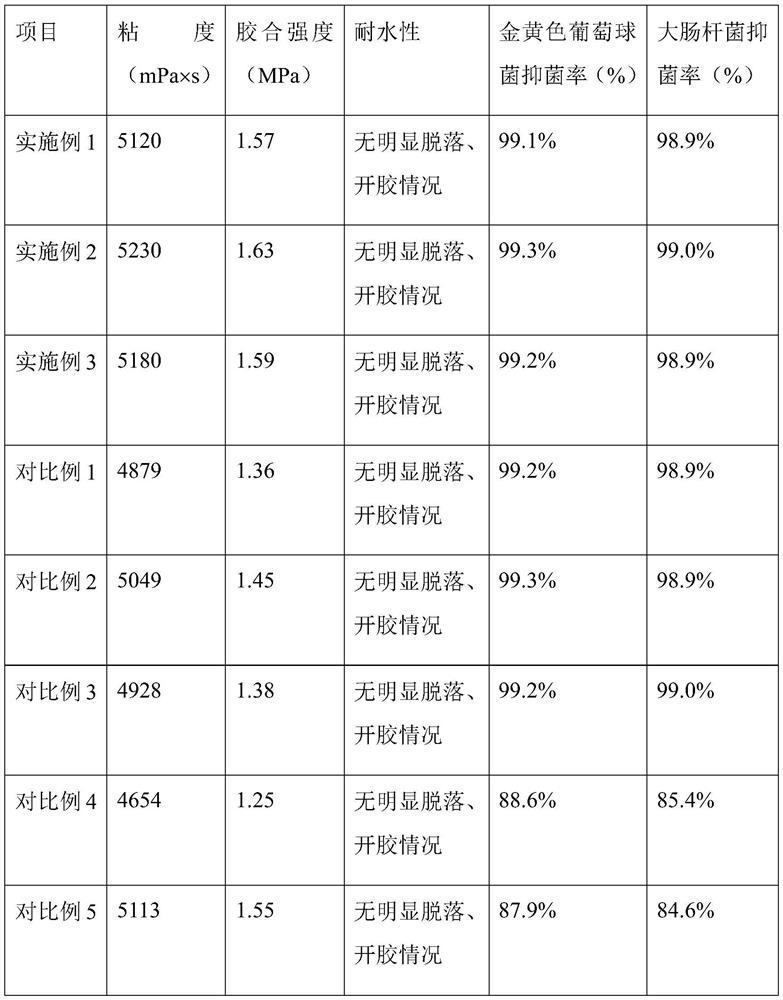

A starch adhesive, bio-oil technology, applied in starch adhesives, cellulose derivative adhesives, adhesives, etc., can solve the problems of poor antibacterial properties, poor water resistance, easy to mold, etc., and achieve excellent water resistance and excellent antibacterial properties. , the effect of improving antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of environment-friendly bio-oil starch adhesive, comprising the following steps:

[0040] (1) Prepare materials:

[0041](2) Take cellulose nanocrystals and deionized water, ultrasonically disperse for 15 minutes, adjust the pH to 4, heat up to 70°C, add 3-aminopropyltriethoxysilane, reflux for 3 hours, cool, and wash with deionized water , collected by centrifugation and dried at 55°C for 10 hours to obtain material A;

[0042] Take formaldehyde and adenosine triphosphate disodium salt solution, mix and stir for 10 minutes, heat up to 110°C, stir and react for 15 minutes, then add material A, continue stirring and reacting for 2 hours, then add silver nitrate solution and ethylene glycol, react for 3 hours, cool to room temperature, Washing with deionized water to obtain modified cellulose;

[0043] (3) Take tartaric acid and deionized water, mix and stir for 10 minutes, add absolute ethanol, treat at a constant temperature at 25°C for 30in, add ...

Embodiment 2

[0050] A preparation method of environment-friendly bio-oil starch adhesive, comprising the following steps:

[0051] (1) Prepare materials:

[0052] (2) Take cellulose nanocrystals and deionized water, ultrasonically disperse for 18 minutes, adjust the pH to 4, heat up to 75°C, add 3-aminopropyltriethoxysilane, reflux for 3.5 hours, cool, and deionized water Wash, collect by centrifugation, and dry at 58°C for 12 hours to obtain material A;

[0053] Take formaldehyde and adenosine triphosphate disodium salt solution, mix and stir for 15 minutes, heat up to 115°C, stir and react for 18 minutes, then add material A, continue stirring and reacting for 2.5 hours, then add silver nitrate solution and ethylene glycol, react for 3.5 hours, and cool to Room temperature, washed with deionized water to obtain modified cellulose;

[0054] (3) Take tartaric acid and deionized water, mix and stir for 15 minutes, add absolute ethanol, treat at a constant temperature of 26°C for 25in, add...

Embodiment 3

[0061] A preparation method of environment-friendly bio-oil starch adhesive, comprising the following steps:

[0062] (1) Prepare materials:

[0063] (2) Take cellulose nanocrystals and deionized water, ultrasonically disperse for 20 minutes, adjust the pH to 4, heat up to 80°C, add 3-aminopropyltriethoxysilane, reflux for 4 hours, cool, and wash with deionized water , collected by centrifugation and dried at 60°C for 14 hours to obtain material A;

[0064] Take formaldehyde and adenosine triphosphate disodium salt solution, mix and stir for 20 minutes, heat up to 120°C, stir and react for 20 minutes, then add material A, continue stirring and reacting for 3 hours, then add silver nitrate solution and ethylene glycol, react for 4 hours, cool to room temperature, Washing with deionized water to obtain modified cellulose;

[0065] (3) Take tartaric acid and deionized water, mix and stir for 20 minutes, add absolute ethanol, treat at a constant temperature at 28°C for 20in, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com