Curing agent with latency for quick thermal curing of acrylic resin

A latent curing agent, acrylic resin technology, used in the field of curing agents, can solve the problems of high curing temperature, no latent, long time, etc., to achieve improved thermal curing efficiency, good latent, curing cross-linking speed and cross-linking speed. The effect of increasing the connection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

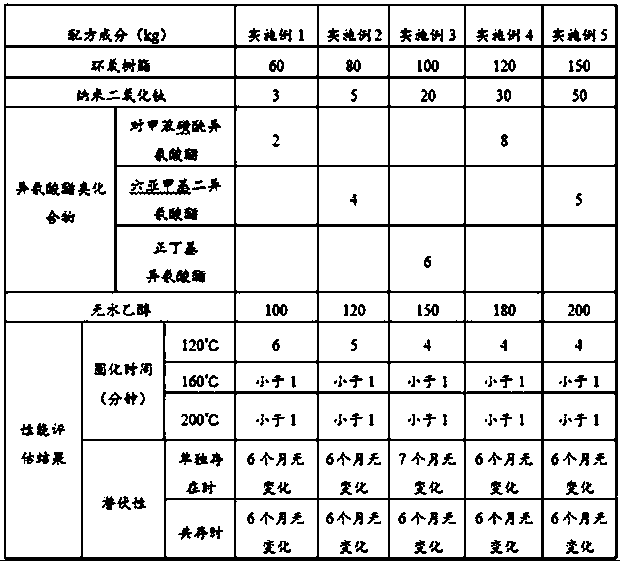

Examples

Embodiment 1

[0032] Embodiment 1: the latent curing agent of rapid thermal curing acrylic resin of the present embodiment, by weight, is made up of following material: epoxy resin 60kg, nano titanium dioxide 3kg, p-toluenesulfonyl isocyanate 2kg, dehydrated alcohol 100 kg.

[0033] Prepare as follows:

[0034] (1) Mix 30kg of epoxy resin with 3kg of nano-titanium dioxide and 50kg of absolute ethanol evenly, and set aside;

[0035] (2) Add 30kg of epoxy resin and 50kg of absolute ethanol to the reaction kettle, adjust the rotation speed to 300 rpm, and mix well;

[0036] (3) Add 2kg p-toluenesulfonyl isocyanate into the reaction kettle, adjust the rotation speed to 500 rpm, and mix and stir for 15-20 minutes;

[0037] (4) Slowly drop the mixture of step (1) into the reactor, and continue to stir for 15-20 minutes after the drop is completed;

[0038] (5) Turn on the condensing device of the reactor, and perform condensing and reflux treatment for 120 minutes;

[0039] (6) Turn on the hig...

Embodiment 2

[0040] Embodiment 2: the rapid thermal curing acrylic resin latent curing agent of the present embodiment, by weight, is made up of following material: epoxy resin 80kg, nano-titanium dioxide 5kg, hexamethylene diisocyanate 4kg, dehydrated alcohol 120 kg .

[0041] Prepare as follows:

[0042] (1) Mix 40kg of epoxy resin with 5kg of nano-titanium dioxide and 50kg of absolute ethanol evenly, and set aside;

[0043] (2) Add 40kg epoxy resin and 60kg absolute ethanol to the reaction kettle, adjust the rotation speed to 300 rpm, and mix well;

[0044] Steps (3)-(6) are carried out with reference to steps (3)-(6) in Example 1.

Embodiment 3

[0046] The rapid heat-curing acrylic resin latent curing agent of the present embodiment is composed of the following materials in parts by weight: epoxy resin 100kg, nano-titanium dioxide 20kg, n-butyl isocyanate 6kg, and dehydrated alcohol 150 kg.

[0047] Prepare as follows:

[0048] (1) Mix 50kg of epoxy resin with 20kg of nano-titanium dioxide and 75kg of absolute ethanol, and set aside;

[0049] (2) Add 50kg of epoxy resin and 75kg of absolute ethanol to the reaction kettle, adjust the rotation speed to 300 rpm, and mix well;

[0050] Steps (3)-(6) are carried out with reference to steps (3)-(6) in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com