Laser transfer paper, and production technology thereof

A laser transfer paper and laser transfer technology, applied in the field of packaging materials, can solve the problems of single laser effect, reduce the quality and production efficiency of the laser transfer paper, light leakage, etc., and achieve the effect of reducing the hydrophilic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

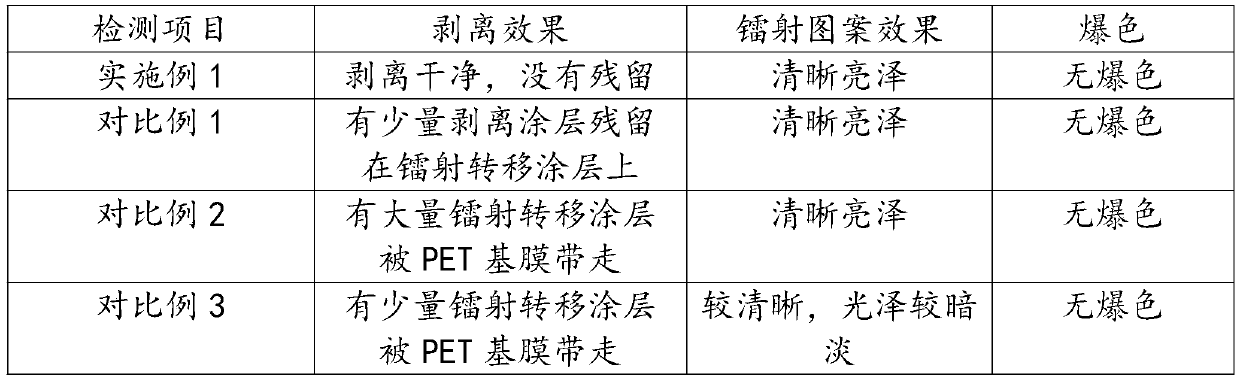

Examples

Embodiment 1

[0043] A laser transfer paper, comprising a laser transfer coating, a laser pattern printed on the laser transfer coating, an aluminum layer coated on the laser transfer coating printed with a laser pattern, coated on the aluminum layer Protective adhesive layer to protect part of the aluminum plating layer, zinc sulfide dielectric layer coated on the protective adhesive layer, and the zinc sulfide dielectric layer is bonded to the paper base through transfer glue;

[0044] The transfer adhesive is an acrylic adhesive;

[0045] The protective adhesive layer is water-based acrylic resin;

[0046] The production process of the laser transfer paper is:

[0047] Step 1. Apply a layer of adhesion-promoting primer on the base film by gravure printing. After drying and drying, apply the release coating on the adhesion-promoting primer, cure and dry to form a peel-off coating, and then transfer the coating by laser Coated on the release coating, and formed a layer of laser transfer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com