Modification method of lowering amount of hydroxyl groups on surface of white carbon black for silicone rubber

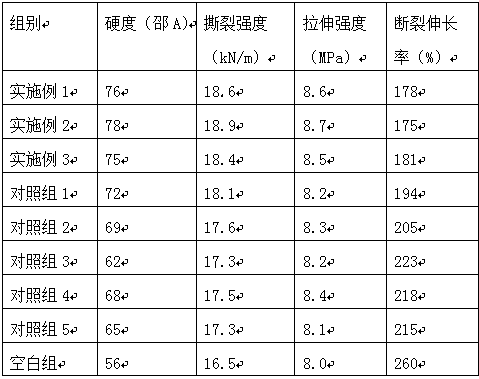

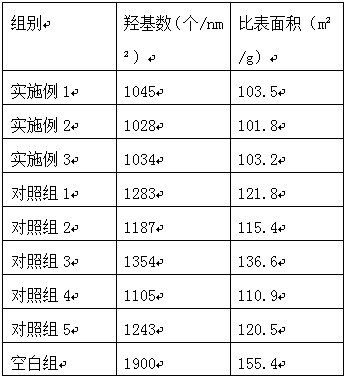

A technology of silica and hydroxyl number, which is applied in the field of modification to reduce the surface hydroxyl number of silica for silicone rubber. It can solve the problems of affecting the interaction of silicone rubber, large specific surface area, and poor dispersion, so as to reduce the number of hydroxyl groups. Number and specific surface area, strengthen the interaction, improve the effect of tear strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A modification method for reducing the number of hydroxyl groups on the surface of white carbon black for silicone rubber, comprising the following steps:

[0018] (1) Immerse white carbon black in a hydrochloric acid solution with a mass concentration of 2.5%, take it out after soaking for 2.5 hours, and mix it with 4% of its weight of phenolic compounds, 2.2% of sodium hexametaphosphate, and 0.4% of bisperoxide 2,4-Dichlorobenzoyl was stirred for 1.5 hours at a temperature of 70° C., filtered with suction after completion, washed until neutral, and dried with hot air to obtain a dried material;

[0019] (2) Mix the dried material with onion essential oil equivalent to 4% of its weight, 15% absolute ethanol, 2% glacial acetic acid, and 1% nitrogen-containing organic base, seal it in a ball mill jar, and ball mill it for 4 hours to obtain a ball mill material;

[0020] (3) Put the ball abrasive into a muffle furnace, raise the temperature to 550° C., and keep it warm f...

Embodiment 2

[0028] A modification method for reducing the number of hydroxyl groups on the surface of white carbon black for silicone rubber, comprising the following steps:

[0029] (1) Immerse white carbon black in a hydrochloric acid solution with a mass concentration of 2%, take it out after soaking for 3 hours, and mix it with 4.5% of its weight of phenolic compounds, 2.6% of sodium hexametaphosphate, and 0.3% of bisperoxide 2, 4-dichlorobenzoyl, stirred at 75°C for 1 hour, suction filtered after completion, washed until neutral, and dried with hot air to obtain a dried material;

[0030] (2) Mix the dry material with onion essential oil equivalent to 6% of its weight, 12% absolute ethanol, 3% glacial acetic acid, and 1.2% nitrogen-containing organic base, seal it in a ball mill jar, and ball mill it for 5 hours to obtain a ball mill material;

[0031] (3) Put the ball abrasive into a muffle furnace, raise the temperature to 500° C., and keep it warm for 40 minutes to obtain white c...

Embodiment 3

[0039] A modification method for reducing the number of hydroxyl groups on the surface of white carbon black for silicone rubber, comprising the following steps:

[0040] (1) Immerse white carbon black in a hydrochloric acid solution with a mass concentration of 3%, take it out after soaking for 2 hours, and mix it with 3.5% of its weight of phenolic compounds, 1.8% of sodium hexametaphosphate, and 0.5% of bisperoxide 2,4-dichlorobenzoyl, stirred at 65°C for 2 hours, suction filtered after completion, washed until neutral, and dried with hot air to obtain a dried material;

[0041] (2) Mix the dry material with onion essential oil equivalent to 2% of its weight, 18% absolute ethanol, 1% glacial acetic acid, and 0.8% nitrogen-containing organic base, seal it in a ball mill jar, and ball mill it for 3 hours to obtain a ball mill material;

[0042] (3) Put the ball abrasive into a muffle furnace, raise the temperature to 600°C, and keep it warm for 30 minutes to obtain white car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com