A Method for Fusion Siliconization of Small-sized Circular Section Ceramic Matrix Composite Components

A technology of composite material components and circular cross-sections, applied in furnaces, lighting and heating equipment, crucible furnaces, etc., can solve the problems of uniform density of components, liquid silicon at the bottom of easy deformation, and difference in internal and external density gradients, and achieve low cost and penetration Simple tooling, prevent easy accumulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053]The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0054] The ceramic-matrix composite material member with a small circular cross-section in the present invention generally refers to a ceramic-matrix composite material member whose maximum circular cross-section diameter is less than or equal to 500 mm and whose height is less than or equal to 500 mm.

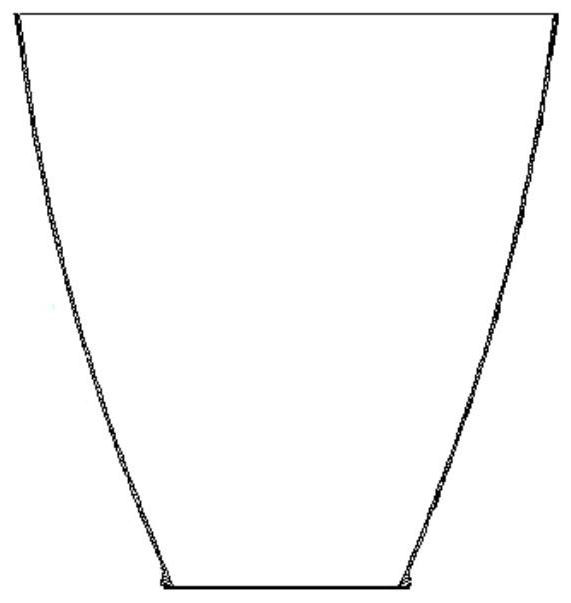

[0055] In this embodiment, the shape of the small-sized circular cross-section ceramic matrix composite member is as follows figure 1 The tapered nozzle shown has a diameter of 500 mm in the radial section at the large end, a diameter of 200 mm in the radial section at the small end, a height of 450 mm, and a wall thickness of 15 mm.

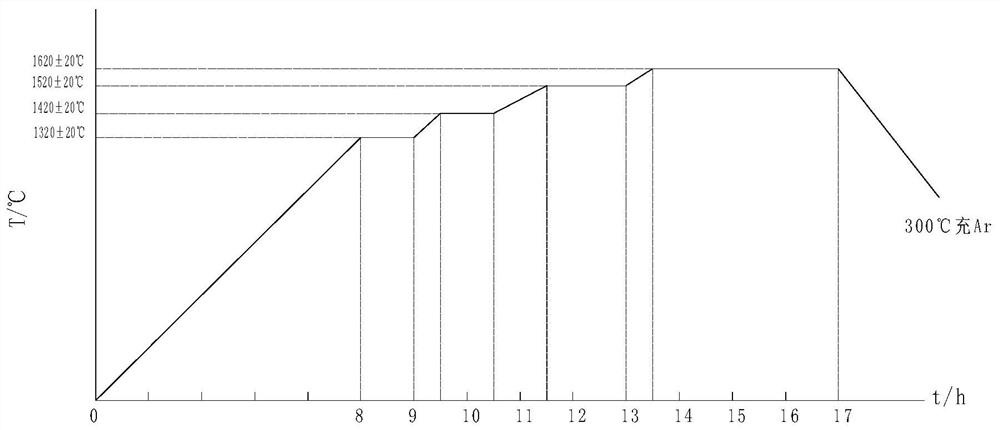

[0056] against figure 1 The components shown in this embodiment adopt the following process to realize fused siliconization:

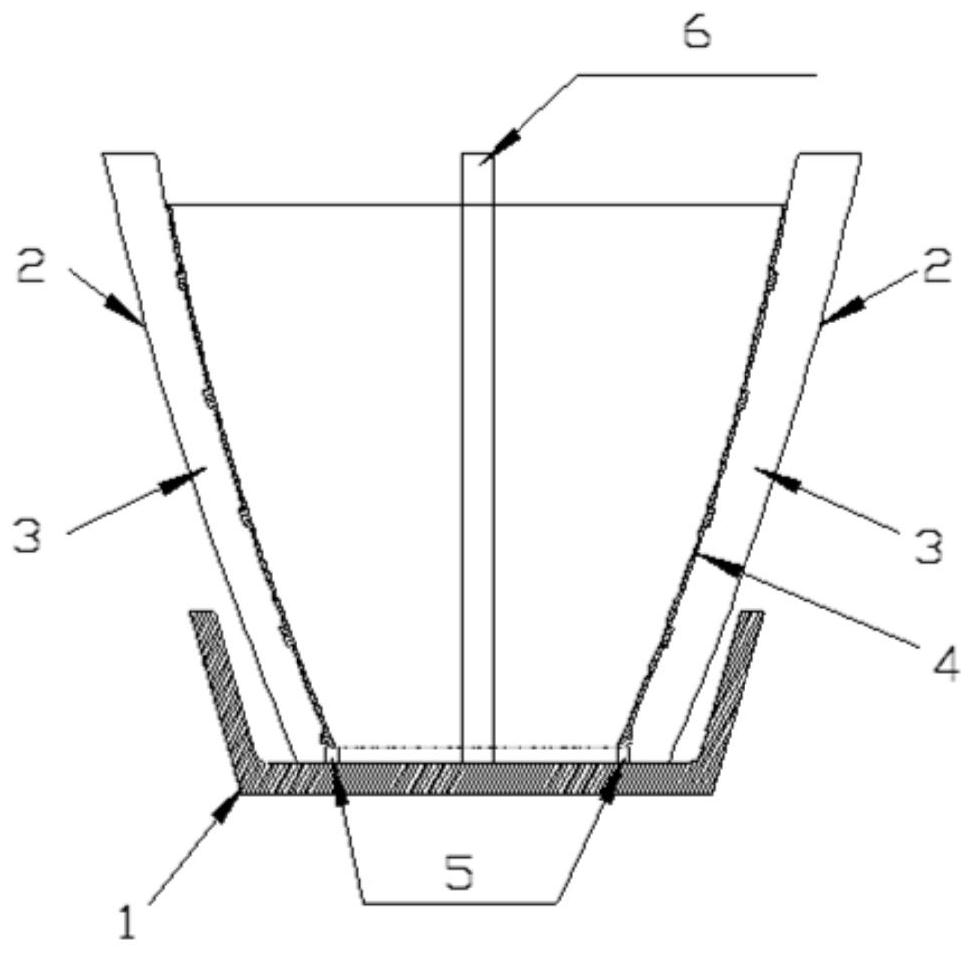

[0057] Step 1, preparing fused silicon infiltration tooling;

[0058] Step 1.1. Win...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com