Method for preparing functional wood by resin impregnation pretreatment of wood

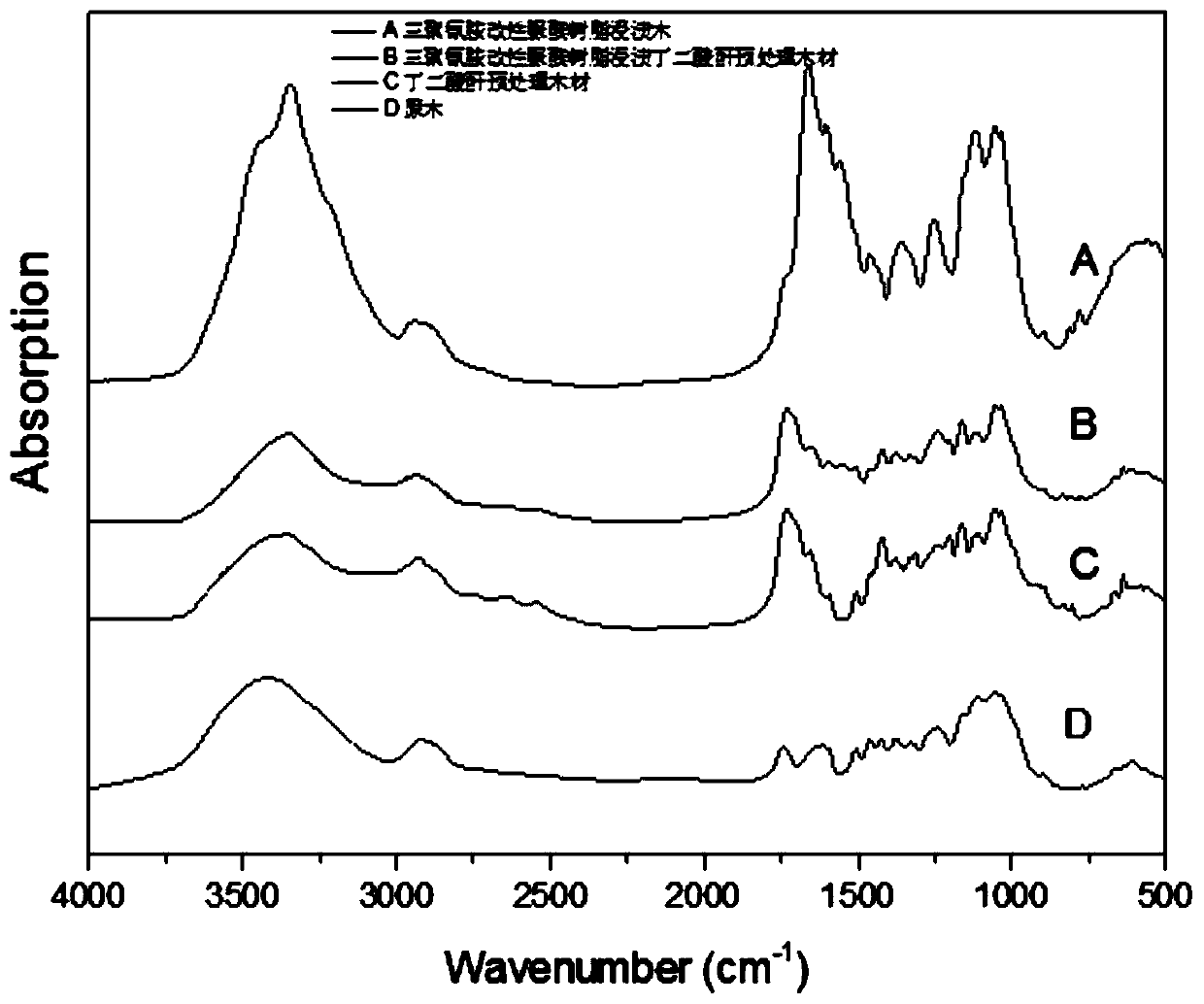

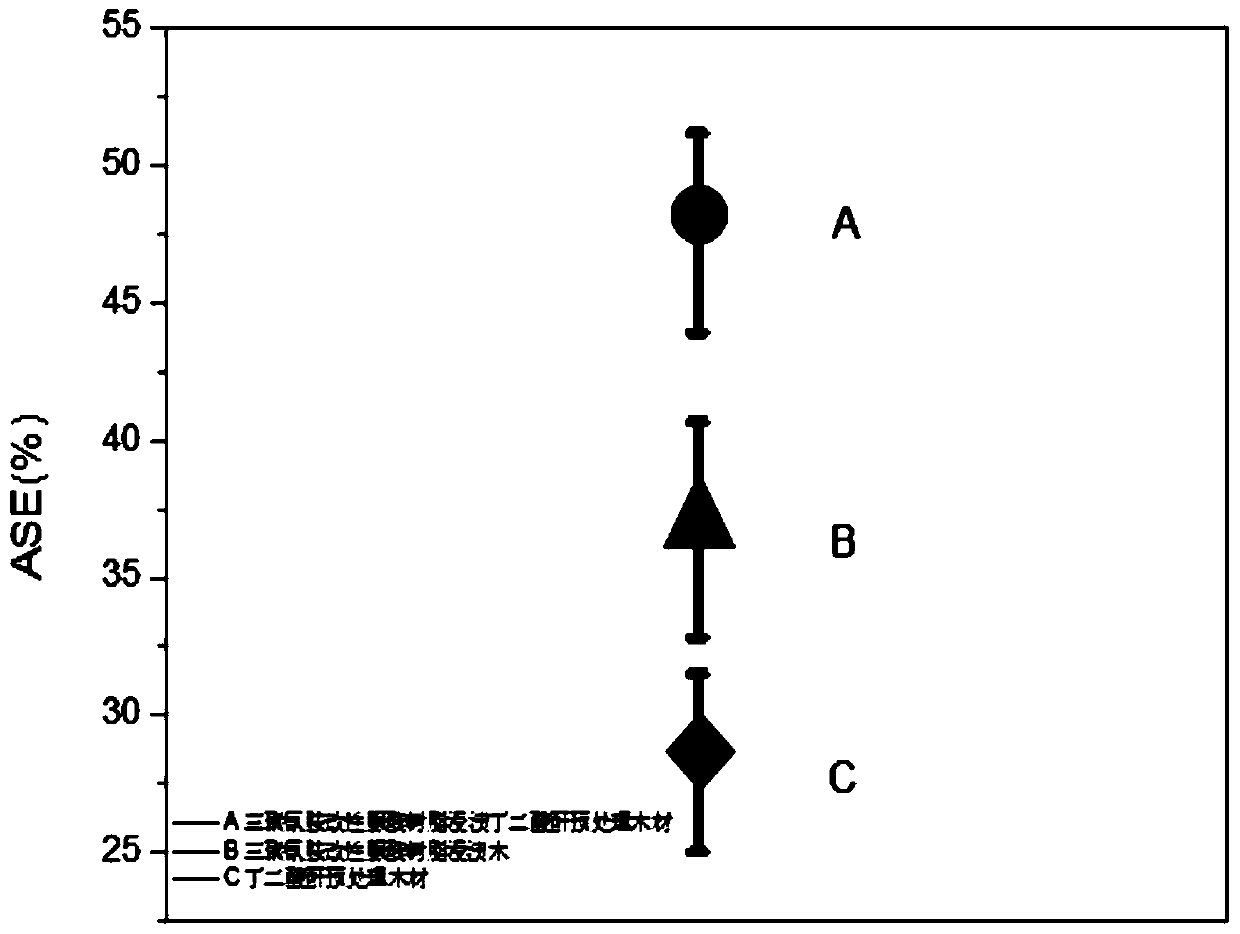

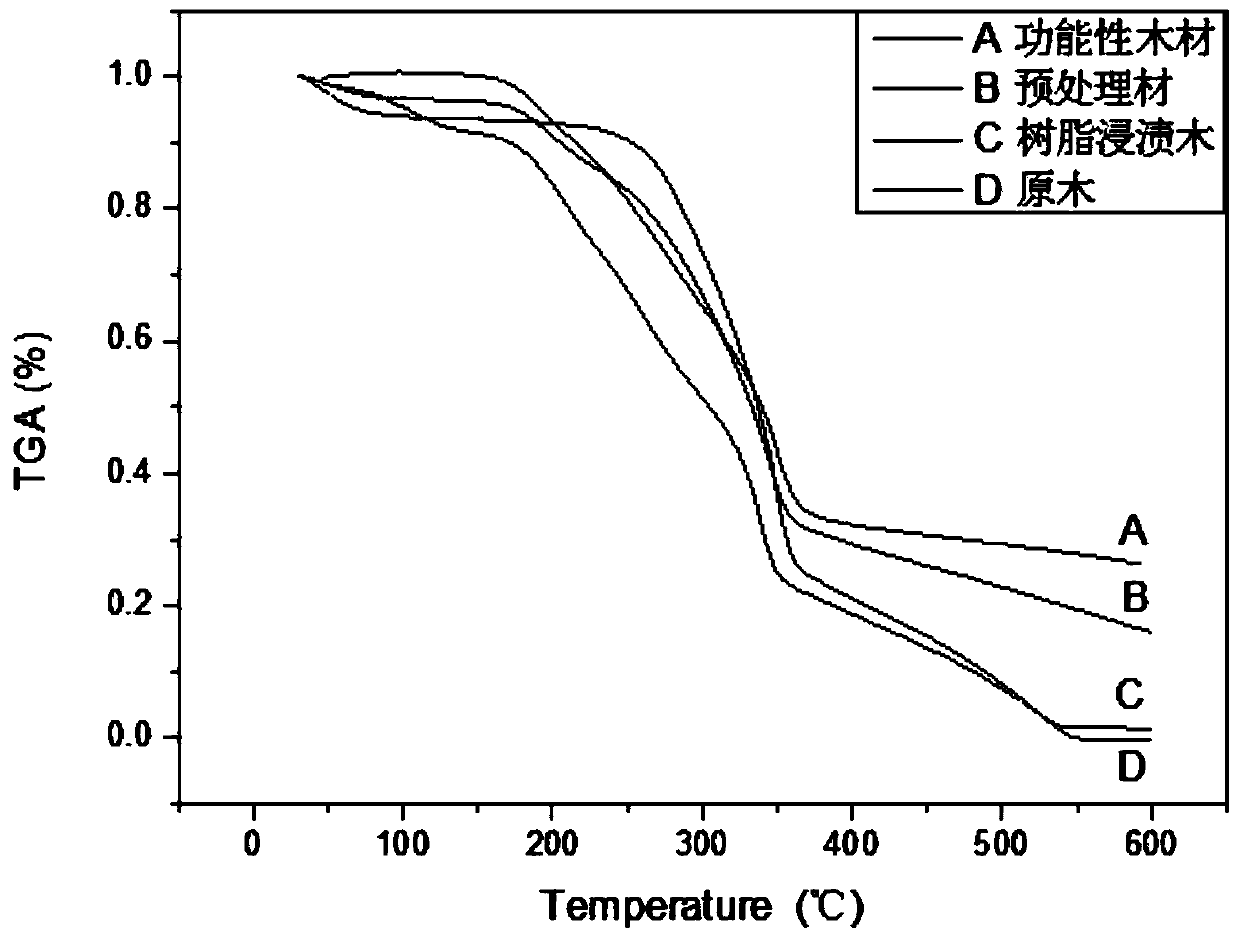

A technology of resin impregnation and pretreatment, which is used in impregnating wood, pretreatment equipment, wood treatment, etc., can solve the problems of single product function, poor durability, complicated preparation process, etc., and achieve simple production process, reduce production cost, and reduce hydroxyl groups. effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Wood pretreatment: Prepare succinic anhydride and N,N-dimethylformamide according to the mass ratio of 1:4 to prepare a pretreatment modifier; first, add succinic anhydride to N,N-dimethylformamide In the amide organic solvent, stir with a magnetic stirrer at a speed of 200rpm for 20min, and heat to 50°C to completely dissolve succinic anhydride. Subsequently, sized pieces of wood were added to the solution and the wood was treated at 70°C for 3 hours.

[0024] (2) Drying treatment: Take the treated wood out of the reaction solution, and after cooling to room temperature, wash the treated wood with ethanol to remove unreacted succinic anhydride and residual N,-N dimethylformamide. Finally, place the wood block in an oven at 70° C. to dry until the moisture content reaches 15%.

[0025] (3) Resin impregnated wood: place the dried pretreated wood in an impregnation tank, vacuumize the inside of the tank to a negative pressure of 0.08-0.1 MPa, and keep it for 40 minut...

Embodiment 2

[0028](1) Wood pretreatment: Prepare succinic anhydride and N,N-dimethylformamide according to the mass ratio of 2:5 to prepare a pretreatment modifier; first, add succinic anhydride to N,N-dimethylformamide In the amide organic solvent, stir with a magnetic stirrer at a speed of 300rpm for 20min, and heat to 50°C to completely dissolve succinic anhydride. Subsequently, sized pieces of wood were added to the solution and the wood was treated at 80°C for 4 hours.

[0029] (2) Drying treatment: Take the treated wood out of the reaction solution, and after cooling to room temperature, wash the treated wood with ethanol to remove unreacted succinic anhydride and residual N,-N dimethylformamide. Finally, place the wood block in an oven at 70° C. to dry until the moisture content reaches 14%.

[0030] (3) Resin-impregnated wood: place the dried pretreated wood in an impregnation tank, vacuumize the inside of the tank to a negative pressure of 0.08-0.1 MPa, and keep it for 40 minute...

Embodiment 3

[0033] (1) Wood pretreatment: Prepare succinic anhydride and N,N-dimethylformamide according to the mass ratio of 1:2 to prepare a pretreatment modifier; first, add succinic anhydride to N,N-dimethylformamide In the amide organic solvent, stir with a magnetic stirrer at a speed of 300rpm for 20min, and heat to 50°C to completely dissolve succinic anhydride. Subsequently, sized pieces of wood were added to the solution and the wood was treated at 90°C for 6 hours.

[0034] (2) Drying treatment: the treated wood was taken out from the reaction solution, cooled to room temperature, and the treated wood was washed with ethanol to remove unreacted succinic anhydride and residual N,N-dimethylformamide. Finally, place the wood block in an oven at 70° C. to dry until the moisture content reaches 13%.

[0035] (3) Resin-impregnated wood: place the dried pretreated wood in an impregnation tank, vacuumize the inside of the tank to a negative pressure of 0.08-0.1 MPa, and keep it for 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com