Special plastic expansion agent for cement-based grouting material and preparation method of same

A plastic expansion agent and plastic expansion technology, which is applied in the field of cement modifiers and special plastic expansion agents for cement-based grouting materials, can solve the problems of uneven gas generation, fast reaction speed, and large gas generation, and achieve simple preparation process, Prevent shrinkage cracks and evenly generate gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

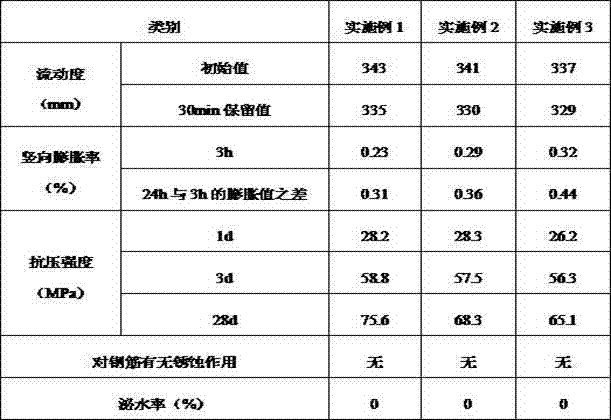

Embodiment 1

[0022] The dedicated plastic expansion agent of the cement grouting material of this embodiment, the weight group is divided into: plastic expansion sources A: 3.0%; hard fatty acid ester B: 0.10%; catalyst C: 6.0%; lime D: 35.0%; water retention agent E E;: 55.9%; accurately weigh the above -mentioned components according to the weight percentage, and systematically systematically produce the present invention.

Embodiment 2

[0024] The dedicated plastic expansion agent of the cement grouting material of this embodiment, the weight group is divided into: plastic expansion sources A: 4.0%; hard fatty acid ester B: 0.12%; catalyst C: 7.0%; lime D: 46.0%; water retention agent E E;: 42.88%; accurately weigh the above -mentioned components according to the weight percentage, and systematically systematically produce the invention according to the process 9.

Embodiment 3

[0026] The dedicated plastic expansion agent of the cement grouting material of this embodiment, the weight group is divided into: plastic expansion sources A: 5.0%; hard ester B: 0.15%; catalyst C: 8.0%; lime D: 45.0%; water preservation agent e: 41.85%; accurately weigh the above -mentioned components according to the weight percentage, and systematically systematically produce the invention according to the process 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com