Elastomer toughening wood-plastic composite material and preparation method thereof

A technology of wood-plastic composite materials and elastomers, applied in the field of wood-plastic composite materials, can solve the problems of limited impact strength improvement, material processing performance decline, and cost increase, and achieve excellent processing performance, good compatibility, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Taking the wood-plastic composite material as 100 parts, the specific preparation method is as follows:

[0028] (1) Mix the raw materials uniformly in a high-speed mixer at room temperature; the reinforcing filler can be activated by combining silane coupling agent, titanate coupling agent or aluminate coupling agent with the reinforcing filler Stir the filler together in a high-speed mixer for 5-10 minutes at high speed;

[0029] (2) Mix and extrude the mixture obtained in (1) in a co-rotating parallel twin-screw extruder to obtain a composite material compound;

[0030] (3) Add the compounded material into a conical twin-screw extruder for extrusion molding to obtain a composite material product.

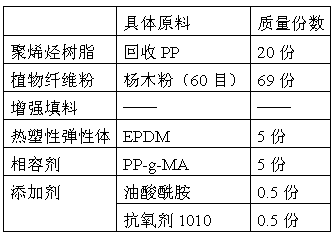

[0031] The raw materials used in Example 1 and the mass parts of each raw material are shown in Table 1.

[0032] Table 1

[0033]

[0034] The Charpy unnotched impact strength of the material obtained in Example 1 is 24kJ / m2, the tensile strength is 41MPa, the bendi...

Embodiment 2

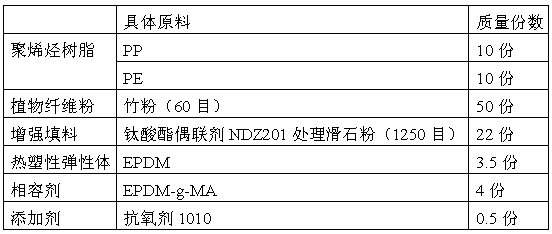

[0036] The raw materials used in Example 2 and the mass parts of each raw material are shown in Table 2, and the preparation method is the same as that of Example 1.

[0037] Table 2

[0038]

Embodiment 3

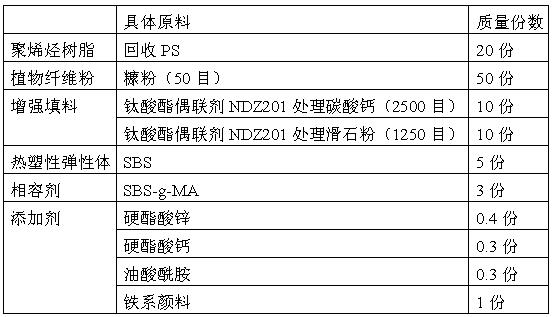

[0040] The raw materials used in Example 3 and the mass parts of each raw material are shown in Table 3, and the preparation method is the same as that of Example 1.

[0041] table 3

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com