Water seepage and crack regional overall treatment method for open excavation tunnel of high speed railway

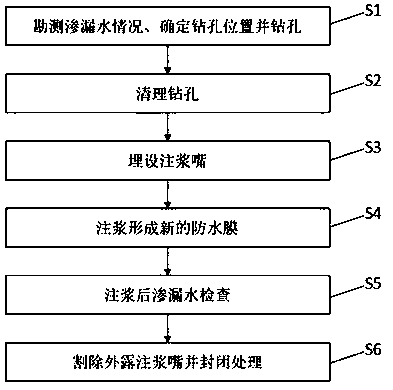

A technology for open-cut tunnels and high-speed railways, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve the problems of consuming manpower, material and financial resources, difficulty in forming a complete structural waterproof system, and repeated water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

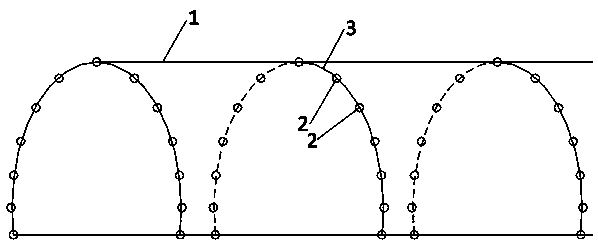

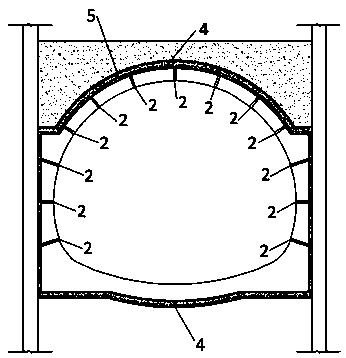

Examples

Embodiment 1

[0056] A newly built high-speed railway tunnel has a starting and ending mileage of DK286+250~DK293+550 (excluding DK288+400~DK290+250), and the total length of the interval tunnel is 5450 m. The tunnel entrance section of a tender section in front of the railway station has a mileage of DK286+250~DK288+400 and a length of 2150 m. It is designed to be constructed by open-cut method. Surface water such as a tributary of a river is distributed in the tunnel area. Although the river has stopped flowing, there is still a small amount of water locally, with a water depth of 0.5-1.5 m. It is corrosive to concrete structures with chloride salts, and the environmental action level is L1. The groundwater in the tunnel area is mainly Quaternary pore water and bedrock fissure water. During the survey period, the groundwater level was buried at a depth of 0.9-3.5 m (elevation 4.05-12.9 m). The groundwater level was relatively high, and it infiltrated along the joints and fissures, forming...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com