Patents

Literature

32results about How to "Ensure safe service" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

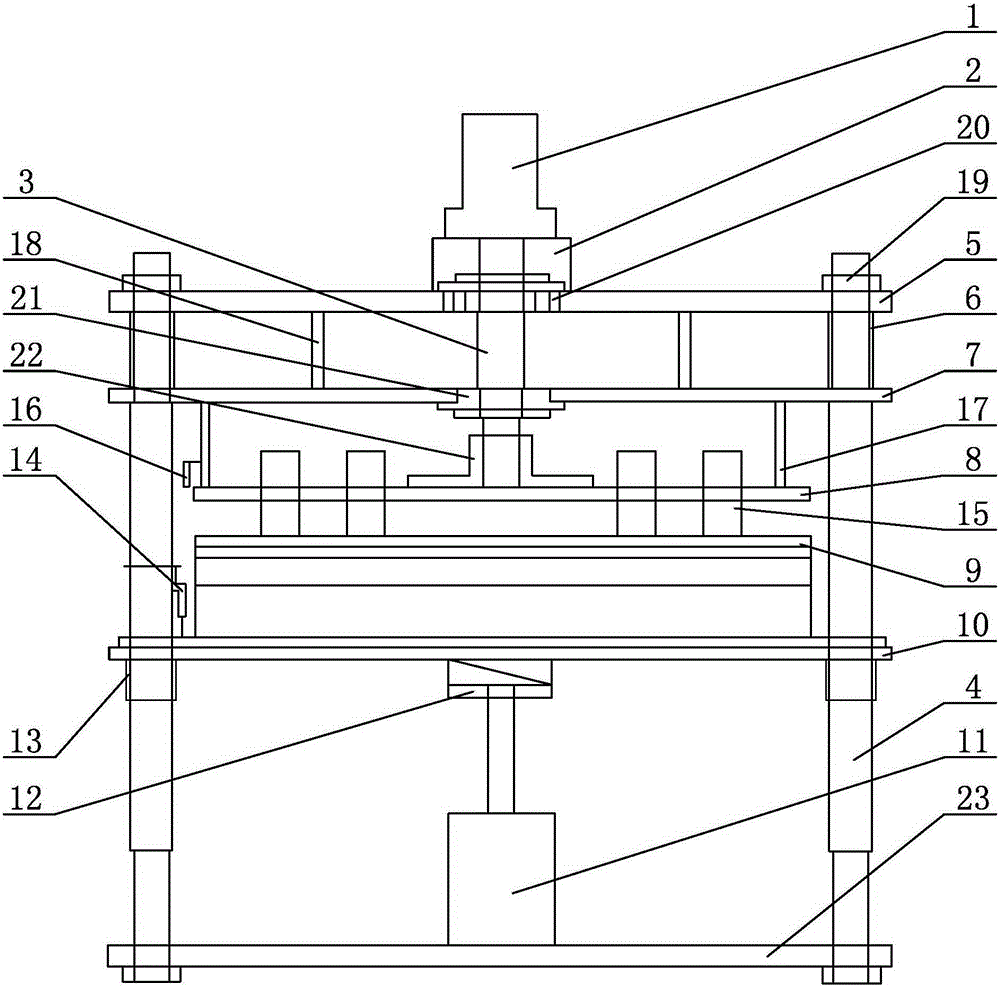

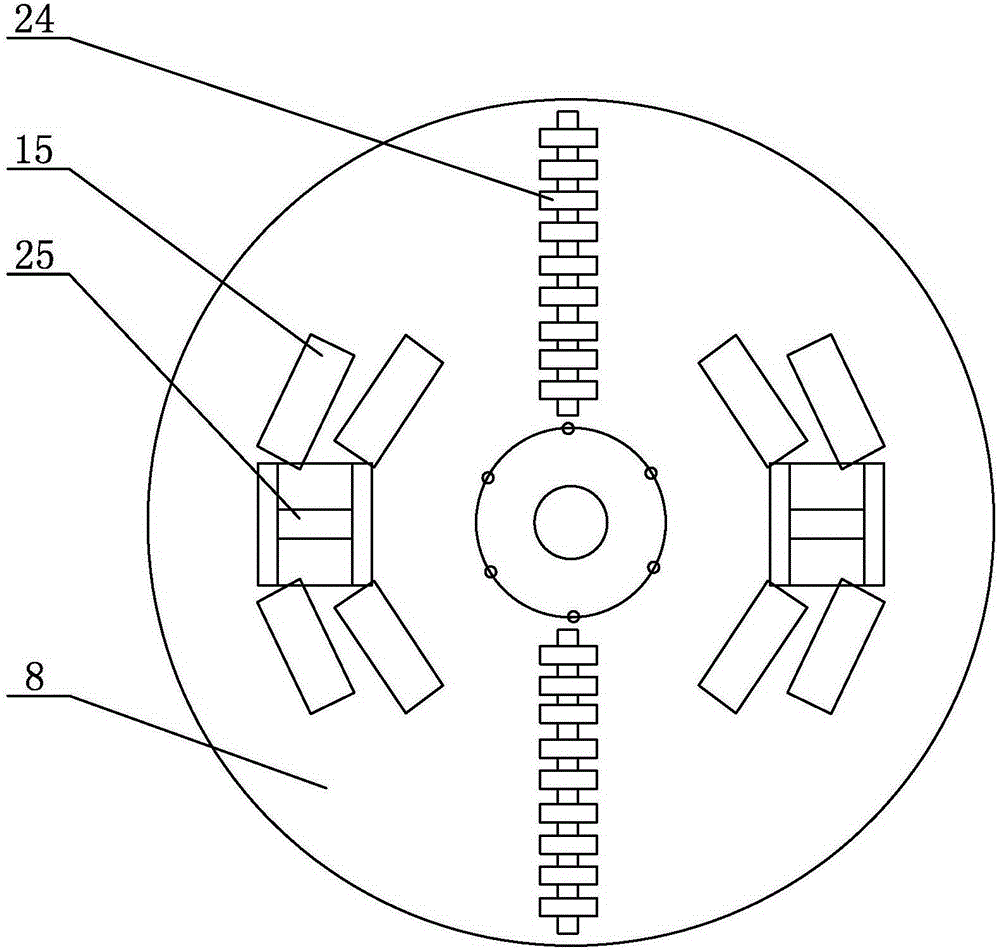

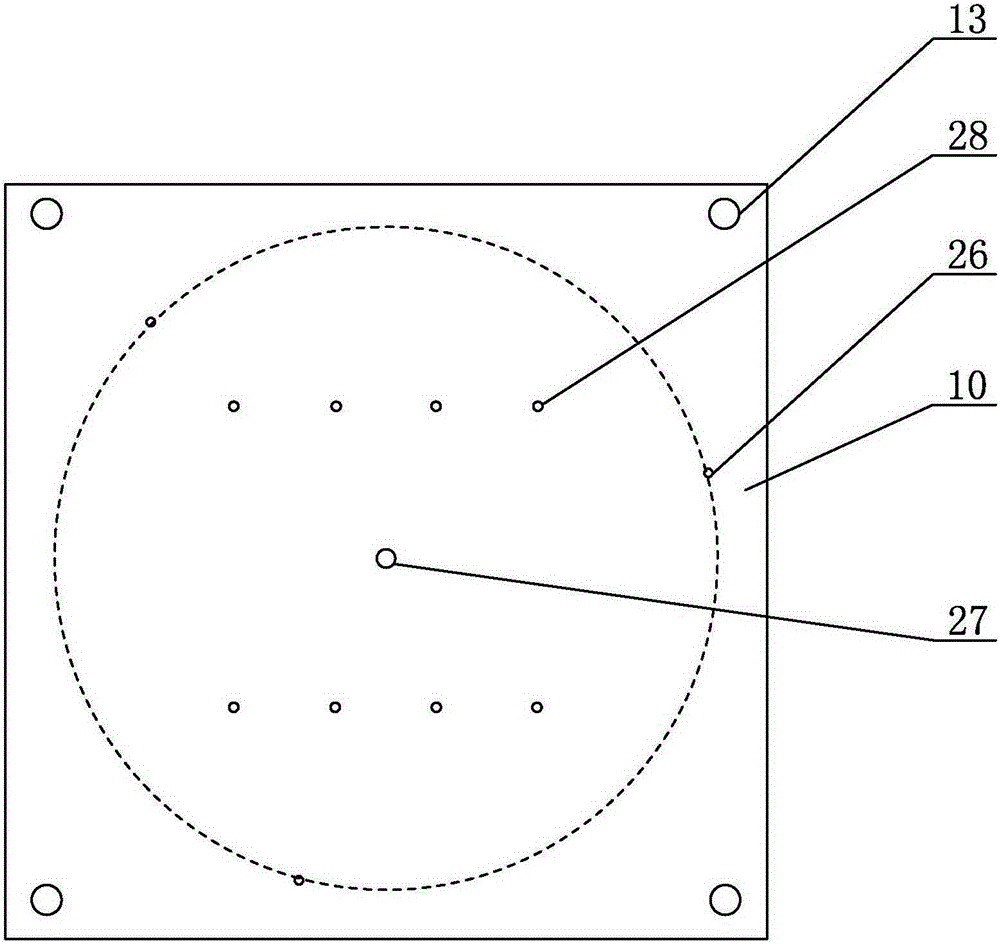

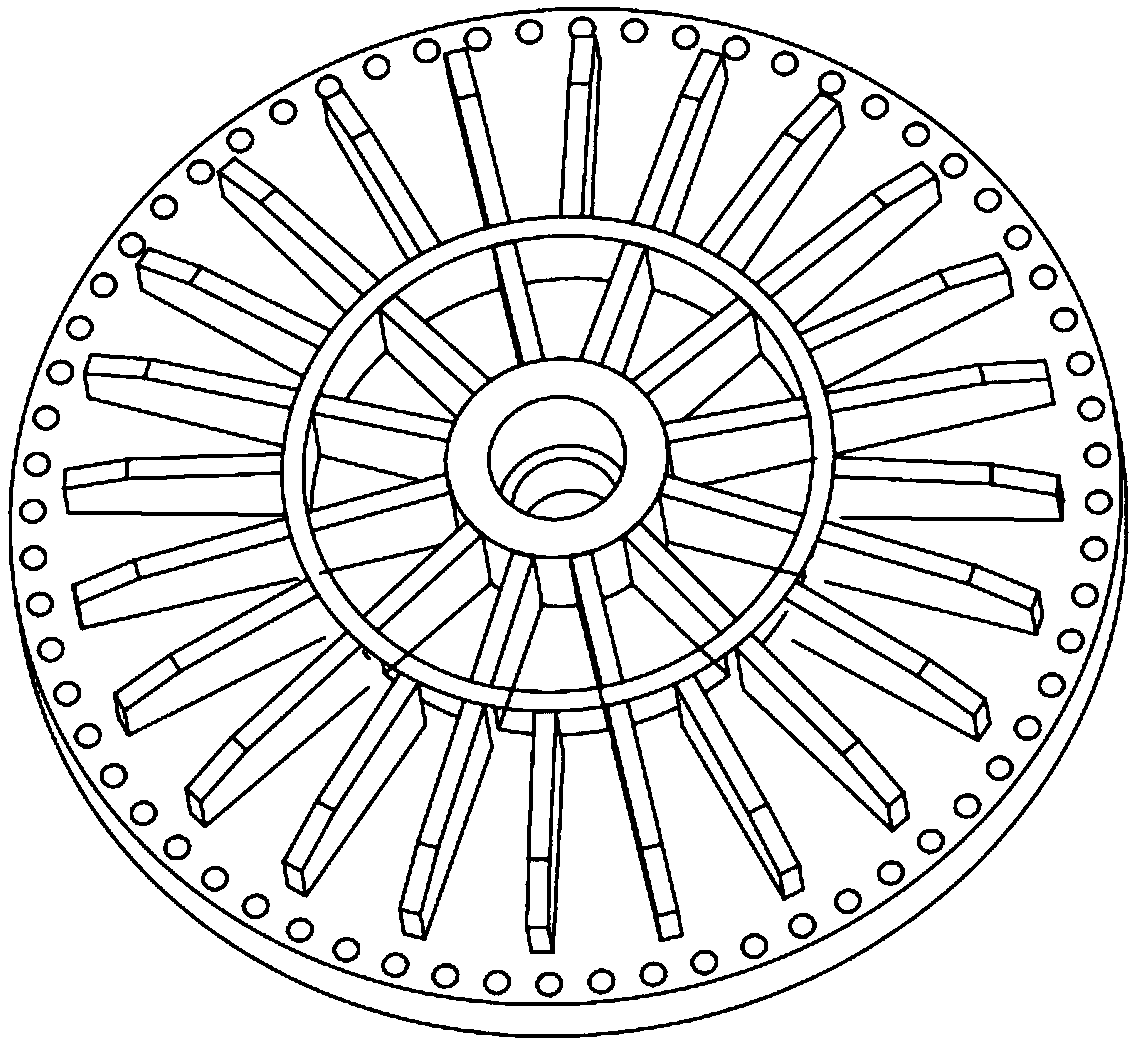

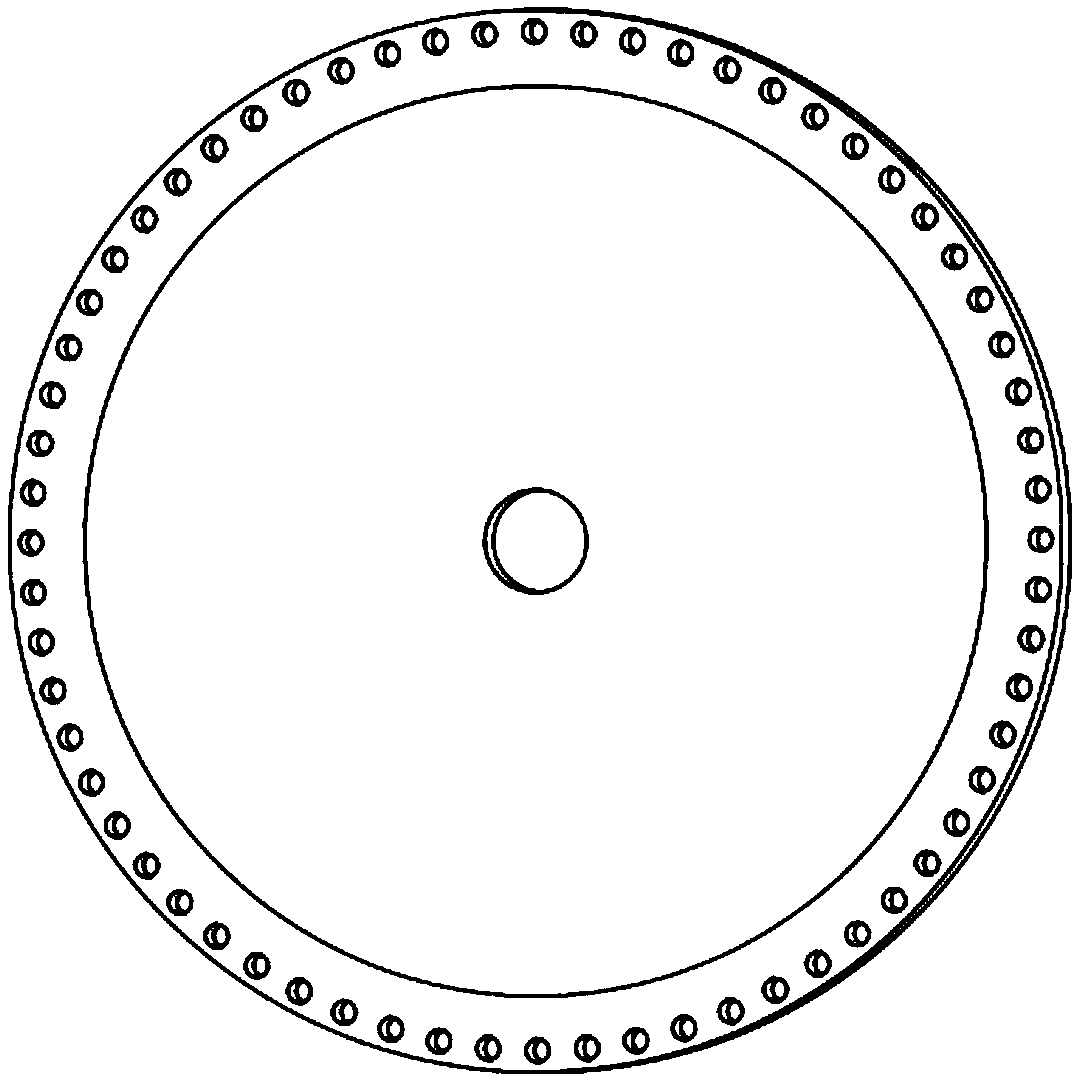

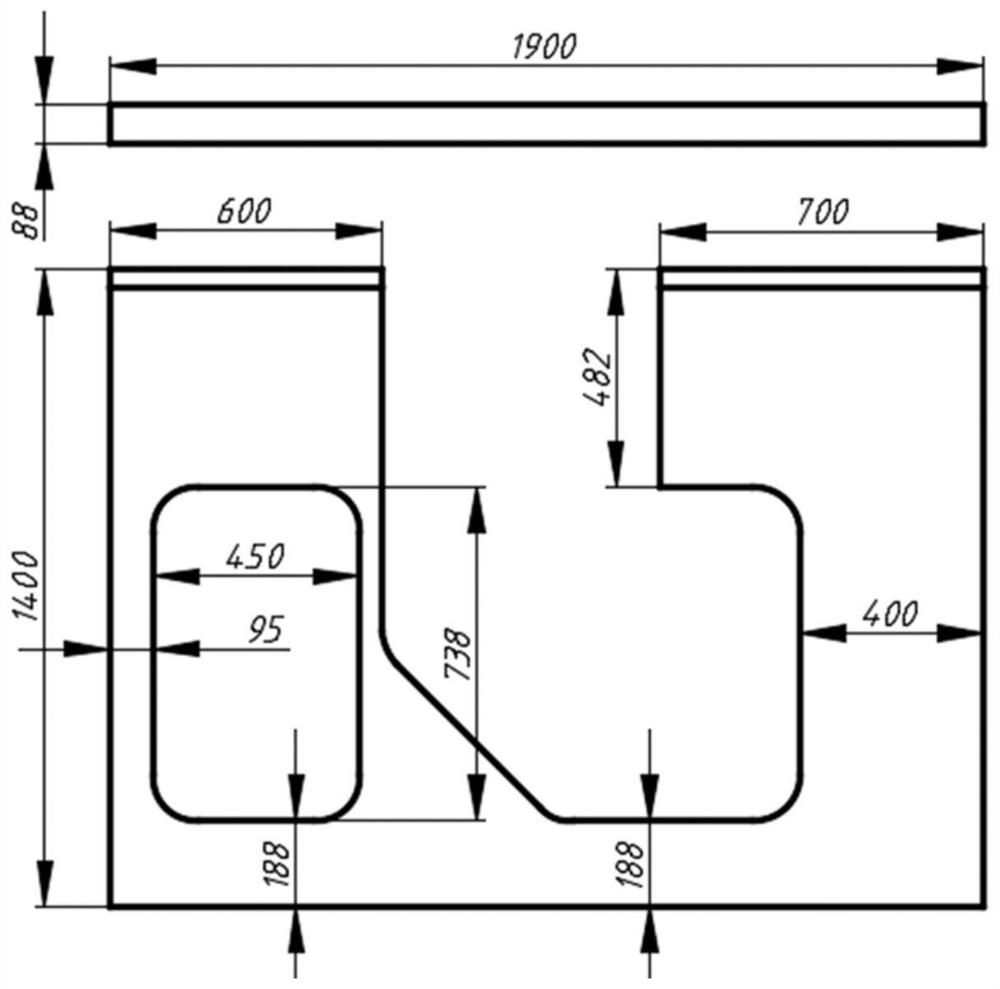

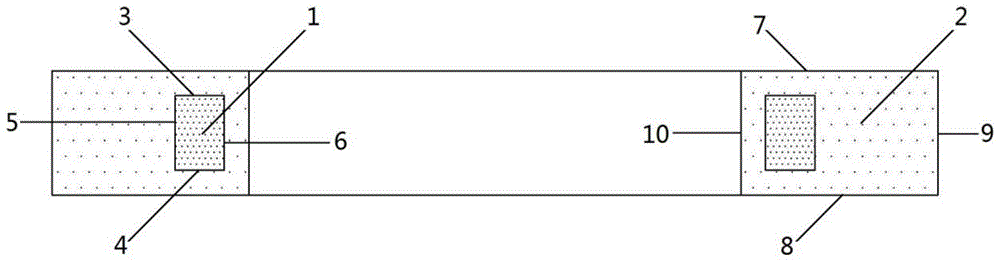

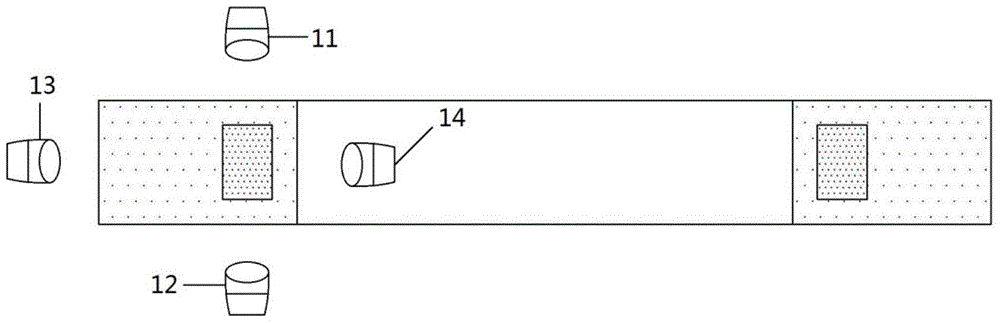

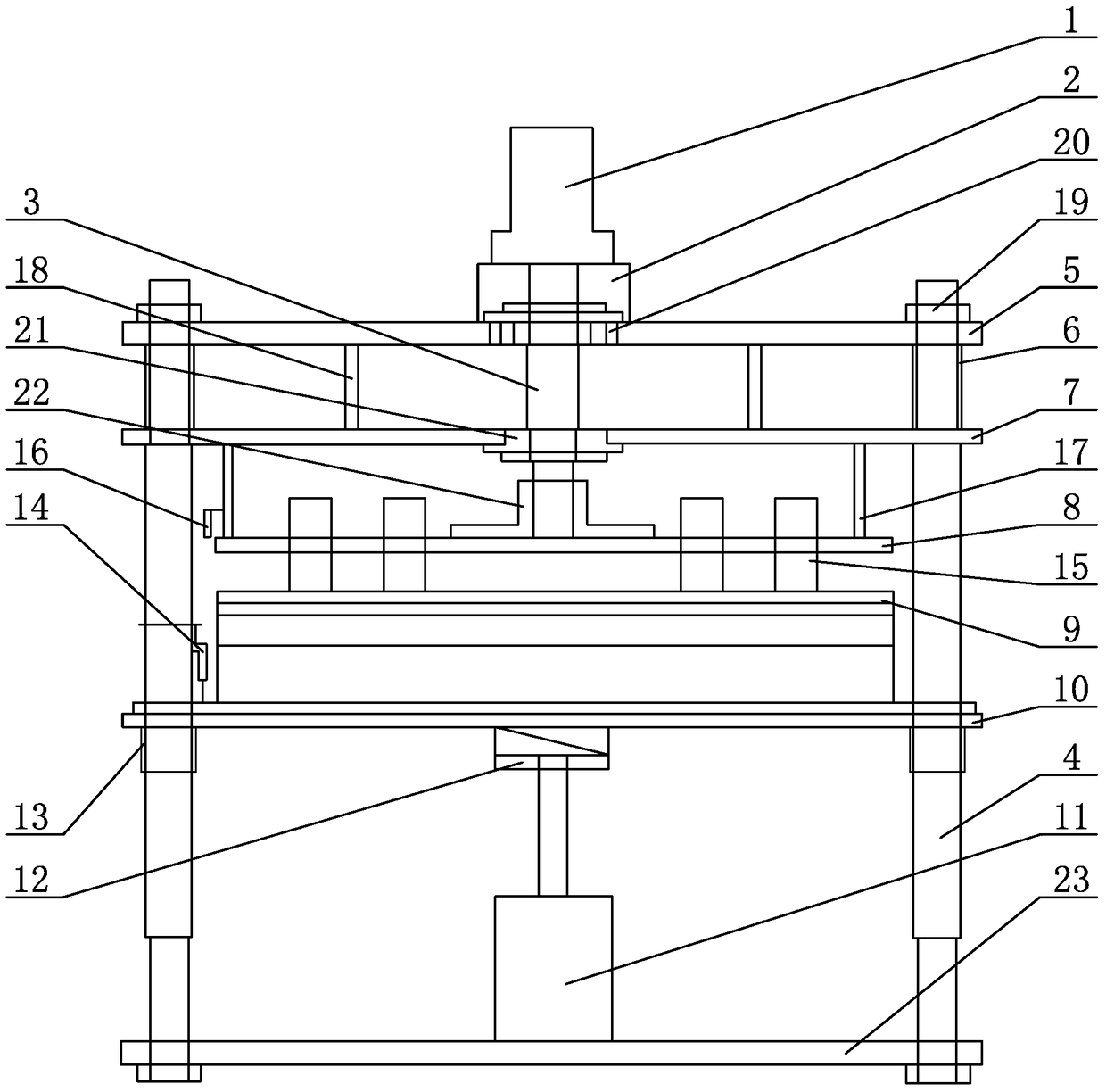

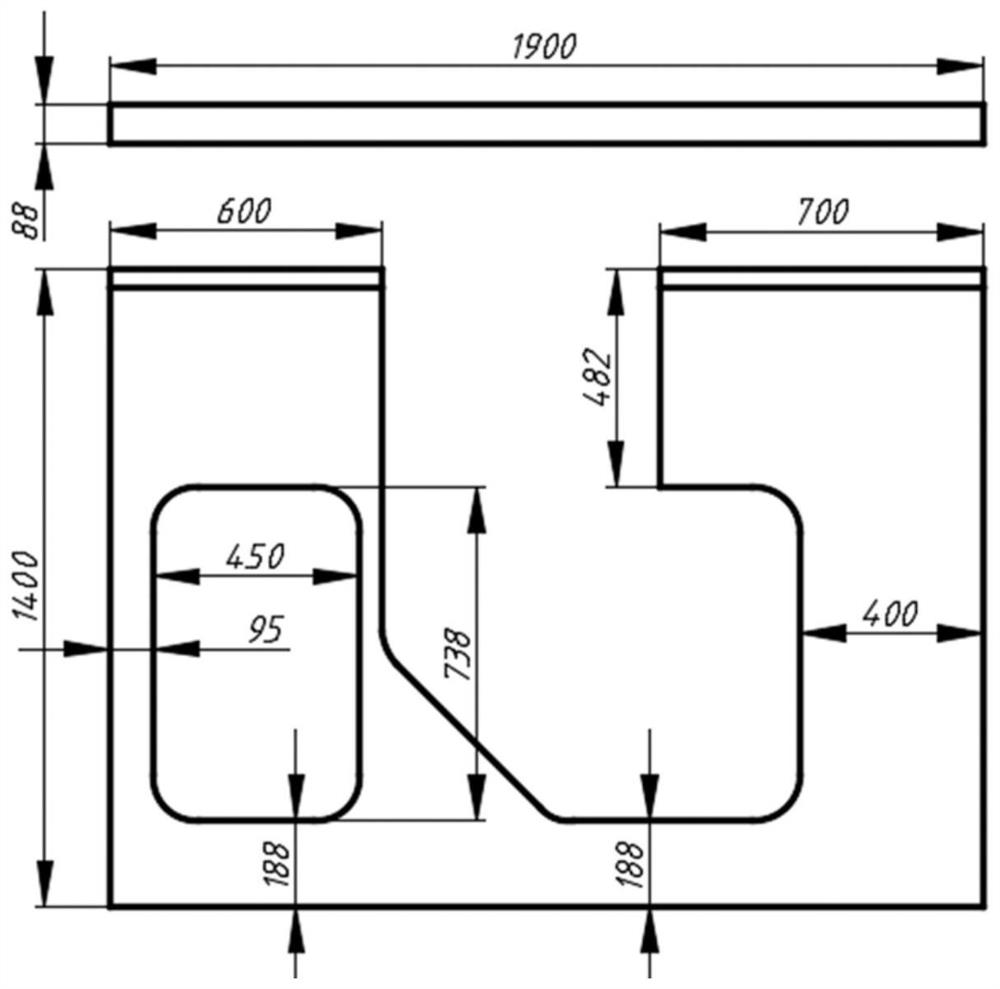

Testing system and testing method applied to testing of high temperature deformation resistance of asphalt airport pavement

ActiveCN105181478AAccurate evaluation of high temperature permanent deformation resistanceEnsure safe serviceMaterial strength using tensile/compressive forcesMaterial strength using steady torsional forcesHydraulic cylinderMaterials testing

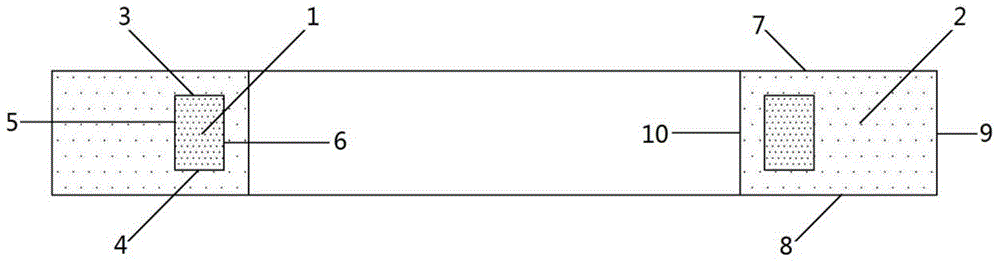

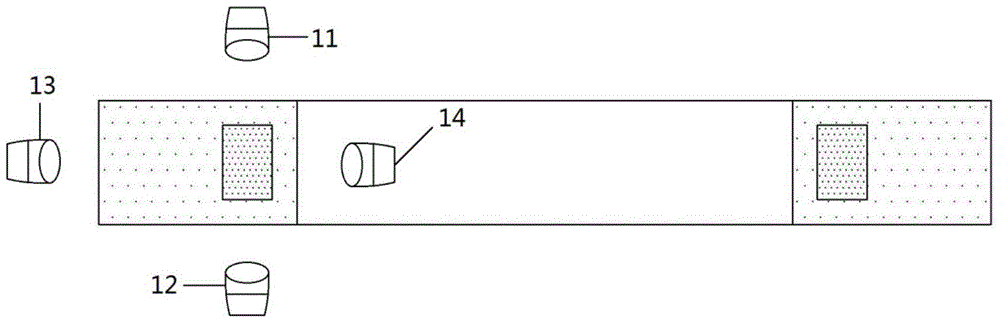

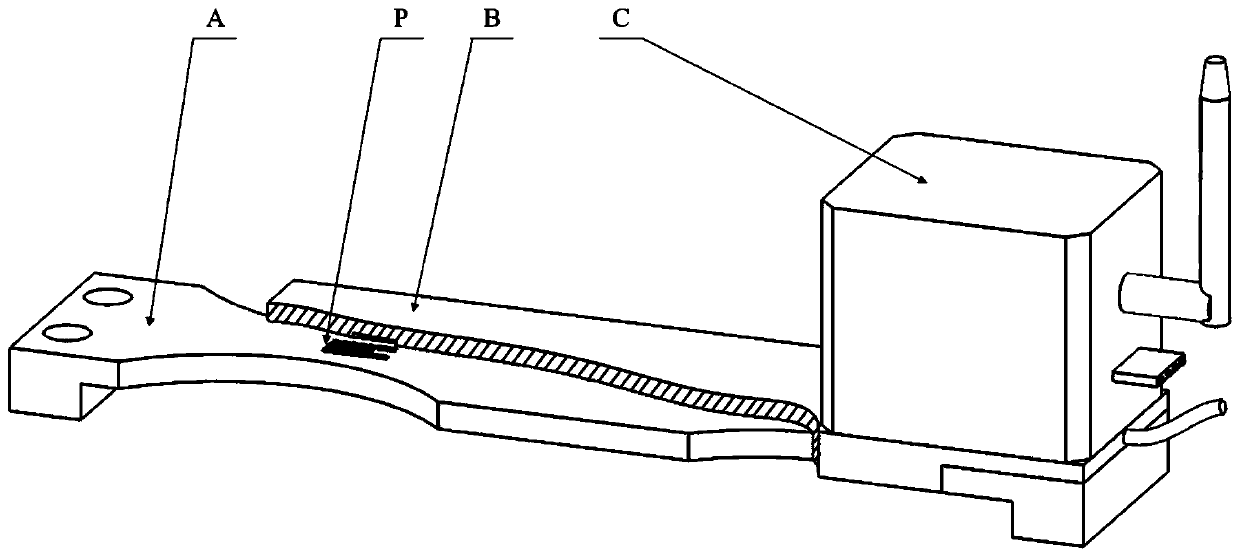

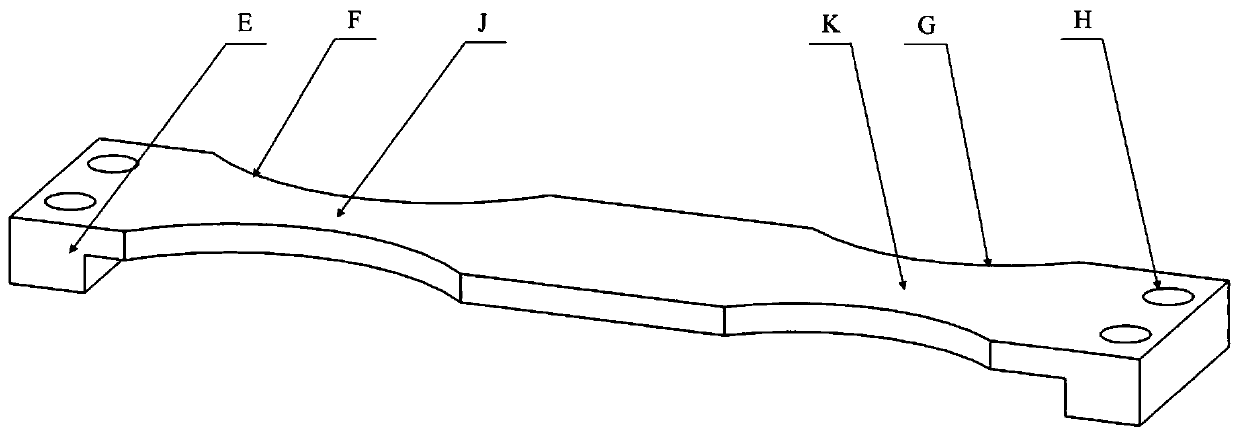

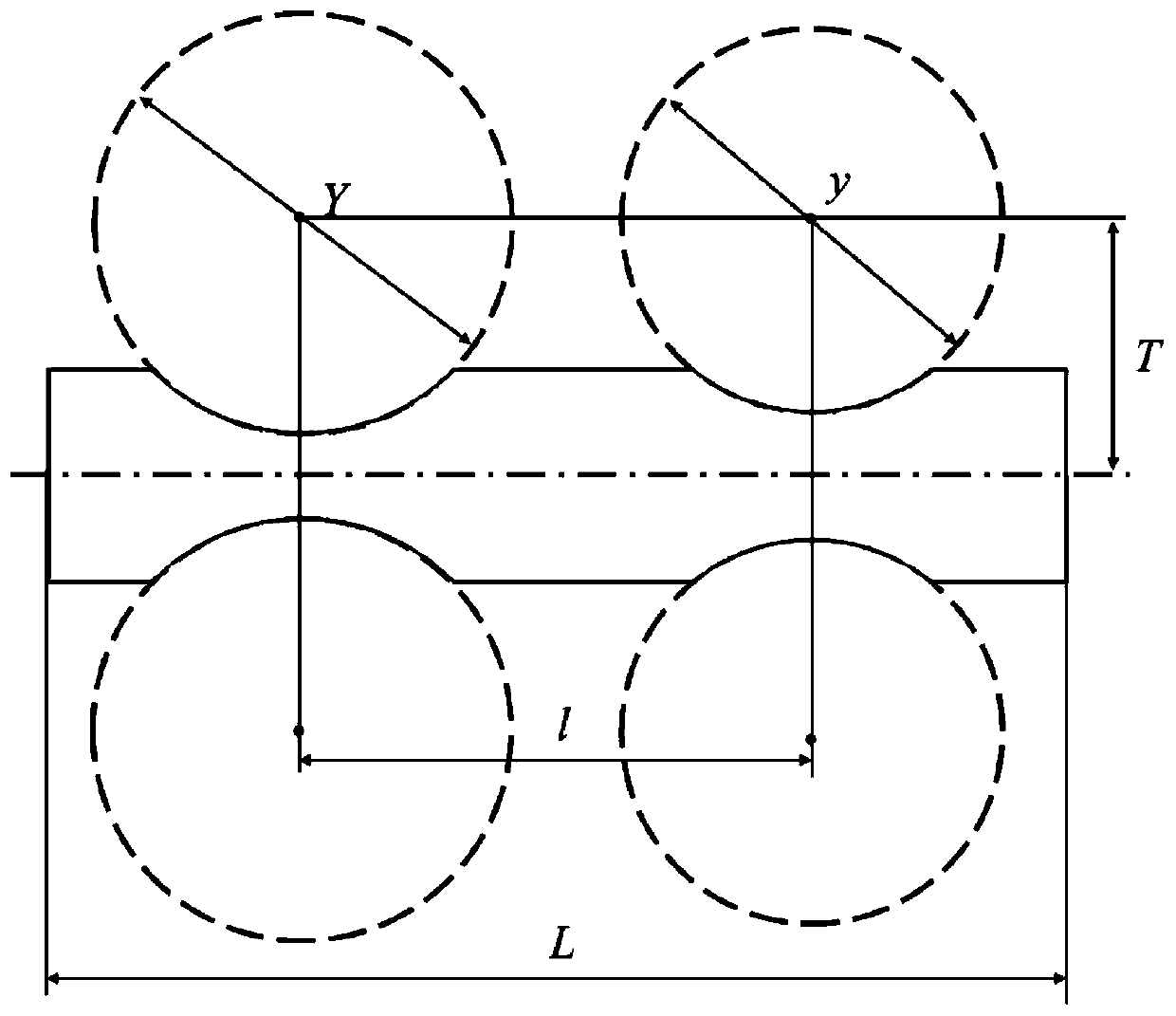

The invention relates to a testing system and a testing method, in particular to a testing system and a testing method applied to a testing of the high temperature deformation resistance of an asphalt airport pavement; the invention aims at solving the problem that an asphalt airport pavement material testing is conducted under the conditions of low load and single-wheel load and the condition that a load action form does not meet the practical situation due to the fact that an existing method of evaluating the high temperature permanent deformation resistance of the asphalt airport pavement depends on a method of evaluating the rutting resistance of a highway engineering bituminous mixture. The testing system disclosed by the invention comprises a motor, a motor supporting seat, a main shaft, a plurality of guide pillars, a top fixed plate, a bottom fixed plate, a rubber wheel supporting disk, a charging tray, a supporting plate, a hydraulic cylinder, a pressure sensor, rubber wheels, a plurality of supporting wheels, an upper bearing block, a lower bearing block, a rubber wheel disk connecting sleeve and a bottom plate; the top fixed plate, the bottom fixed plate, the supporting plate and the bottom plate are arranged in parallel from top to bottom in sequence; the guide pillars are evenly distributed. The testing system and the testing method disclosed by the invention are used for the field of road and bridge construction.

Owner:HARBIN INST OF TECH +2

Method for rapidly repairing cement emulsified asphalt mortar interface connection damage of unit slab ballastless track

ActiveCN104480815AGuaranteed smoothnessEasy constructionRailway track constructionPressure groutingComing out

The invention relates to a method for rapidly repairing cement emulsified asphalt mortar interface connection damage of a unit slab ballastless track; the method mainly comprises the steps of cleaning, sealing, setting of grouting openings, interface connection damage grouting and edging treatment; the specific steps are as follows: firstly, cleaning dust and impurities around a mortar interface connection damage; secondly sealing the interface connection damage area, setting the grouting openings and placing a dial indicator at four corners of a track slab in a to-be-repaired area; thirdly, connecting a dual-component self-mixing grouting machine with a pressure grouting hose, and injecting a dual-component grouting material to the grouting openings in sequence; after the mortar comes out of a grouting opening having the spacing of more than the width of the track slab with the next grouting openings, turning to the next grouting opening to grout continuously till the whole cement emulsified asphalt mortar seam area is fully grouted; and finally, cutting the grouting hose, polishing sealed materials to finish the repairing. The method has the characteristics of simple and rapid process, high repairing efficiency and capability of realizing rapid repairing within skylight time and is applicable to repairing the cement emulsified asphalt mortar seams of the unit slab ballastless track.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

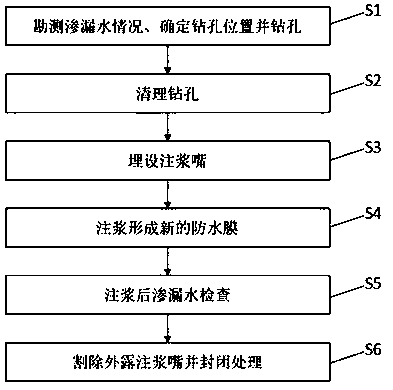

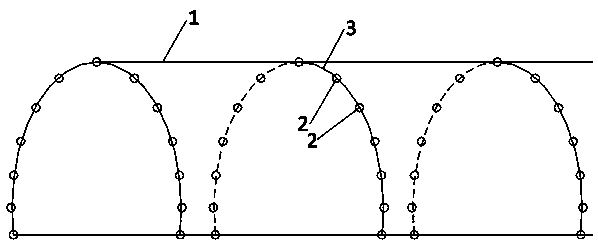

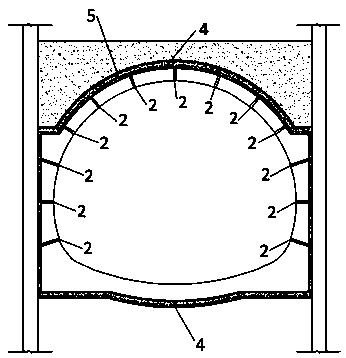

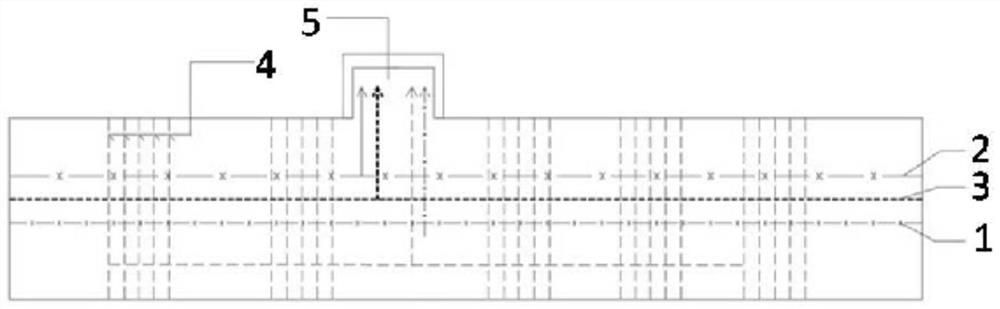

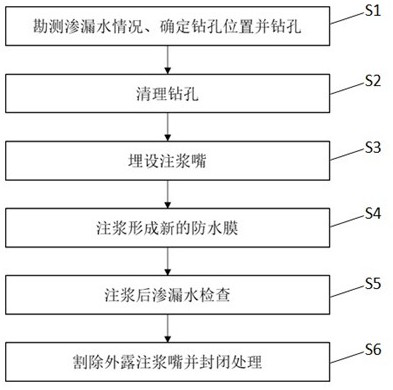

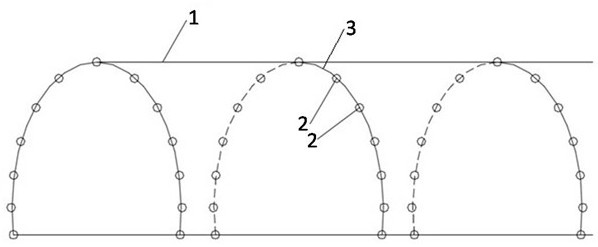

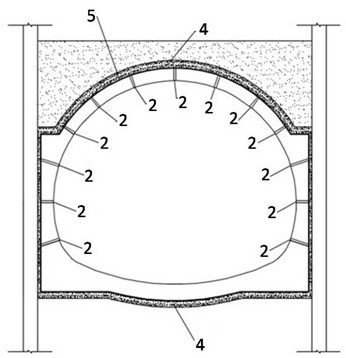

Water seepage and crack regional overall treatment method for open excavation tunnel of high speed railway

ActiveCN109653777AEven groutingEnsure safe serviceUnderground chambersTunnel liningWater leakageUltimate tensile strength

The invention discloses a water seepage and crack regional overall treatment method for an open excavation tunnel of a high speed railway. The method comprises the following steps: surveying a water leakage situation, determining a drilling position and drilling; cleaning the drilled hole; embedding a grouting nozzle; grouting to form a new waterproof membrane; performing water leakage inspectionafter grouting is performed; and cutting and removing the exposed grouting nozzle and performing sealing treatment. The invention provides the water seepage and crack regional overall treatment methodfor the open excavation tunnel of the high speed railway which forms integrated structural strength by lining aiming at the characteristics of the open excavation tunnel of the high speed railway, particularly at the complex tunnel situations of large number of water leakage cracks, wide distribution range and the leakage of unplugged cracks in the periphery caused by plugging one crack; integrated grouting in rings in the overall cross section is adopted, and grouting holes are uniformly distributed in each ring, so that uniform grouting at the positions, such as an arch top, a hance and a side wall, can be realized; and regional overall treatment is performed to form a new waterproof system, so that guarantee is provided for safety service of a tunnel structure.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

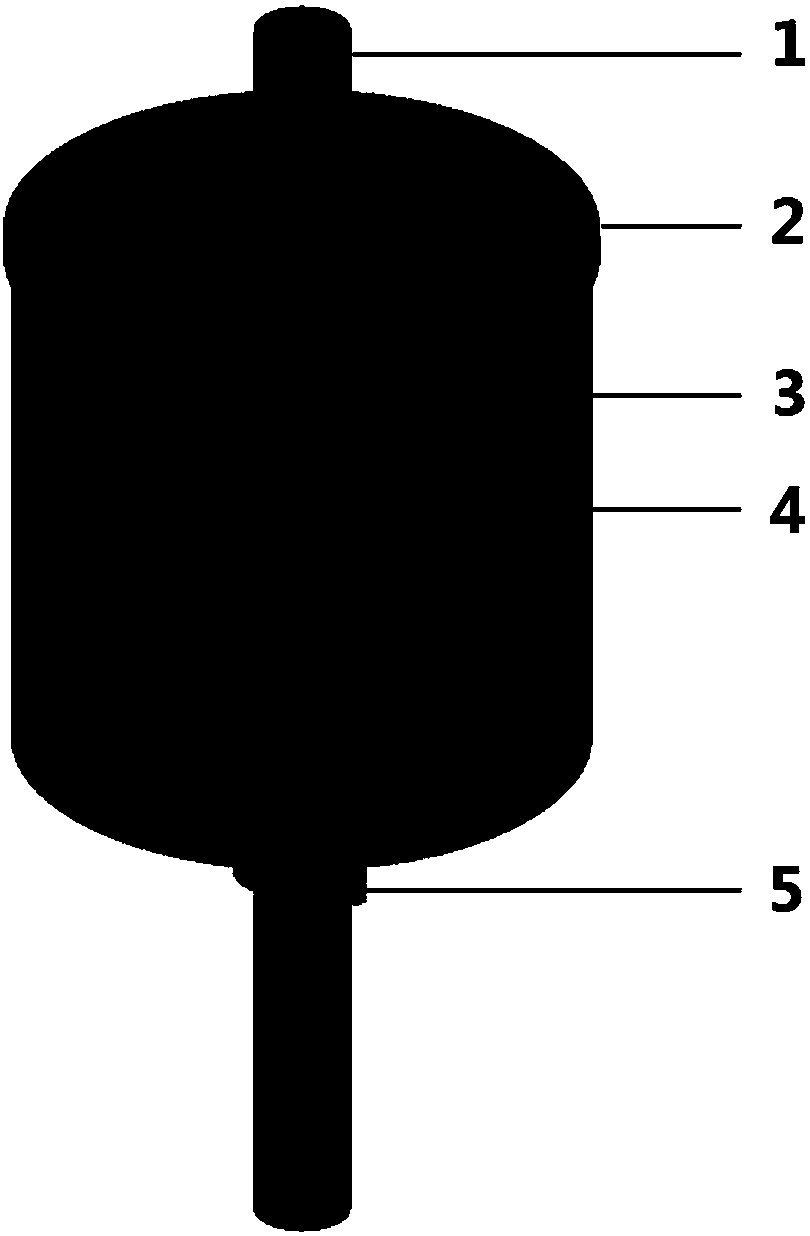

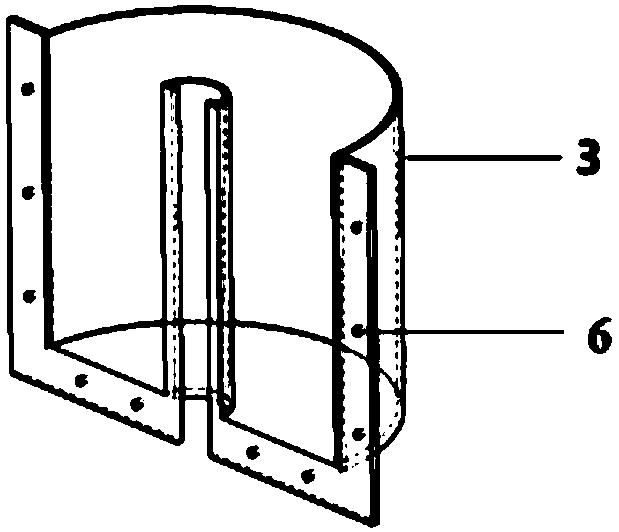

Annular cylindrical tuned liquid damper for controlling vibration of long boom of long-span bridge, and design method

PendingCN107657126AReduce vibration response amplitudeImprove fatigue resistanceGeometric CADBridge structural detailsVibration controlEngineering

The invention discloses an annular cylindrical tuned liquid damper for controlling vibration of a long boom of a long-span bridge, and a design method, and belongs to the technical field of engineering structure vibration control. A box body bracket is mounted in a central point of a to-be-controlled boom, and then two split box bodies are spliced and mounted on the box body bracket; and accordingto a set height, a damping liquid is added into a damper box body, and a top cover on the upper side is closed to prevent the liquid from being splashed or volatilized. The liquid in the box body shakes for consuming energy and applying a lateral force to a barrel wall, thereby realizing control on a power response of the boom. A calculation method for specific parameters of the annular cylindrical tuned liquid damper is given in the patent; and the damper has the advantages of good shock absorption effect, low mounting and repair costs, convenient repair, easy tuning and the like, and is ofpositive significance for prolonging the service life of the boom and guaranteeing safe service of the boom.

Owner:DALIAN UNIV OF TECH

Progressive control method of railway open trench tunnel lining deformation joint leakage water

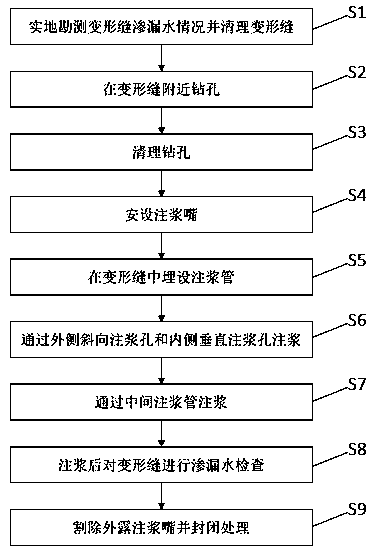

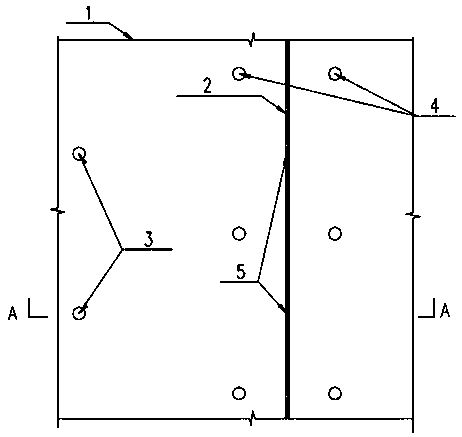

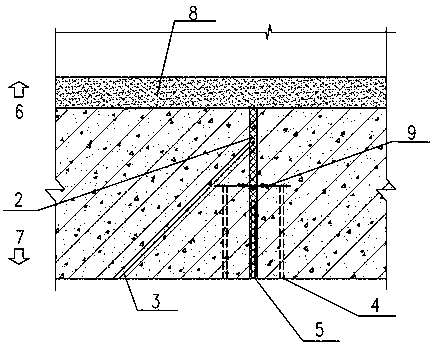

The invention discloses a progressive control method of railway open trench tunnel lining deformation joint leakage water. The method comprises the following steps of performing field investigation onthe deformation joint leakage water condition; cleaning a deformation joint; drilling a hole near the deformation joint; cleaning the drill hole; installing a grouting nozzle; burying a grouting pipeinto the deformation joint; performing grouting through an outer side inclined grouting hole and an inner side vertical grouting hole; performing grouting through a middle grouting pipe; after the grouting, performing seepage water inspection onto the deformation joint; cutting away the externally exposed grouting nozzle; and performing sealing treatment. By aiming at the characteristics of a railway open trench tunnel, the invention provides the progressive control method of railway open trench tunnel lining deformation joint leakage water for implementing the complete sealing and blockage on a leakage water passage; the progressive grouting sealing and blockage on the deformation joint is realized through sequentially performing grouting on the outer side inclined grouting hole, the inner side vertical grouting hole and the middle grouting pipe; the leakage water passage is completely cut; and the guarantee is provided for the safe service of a tunnel structure.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

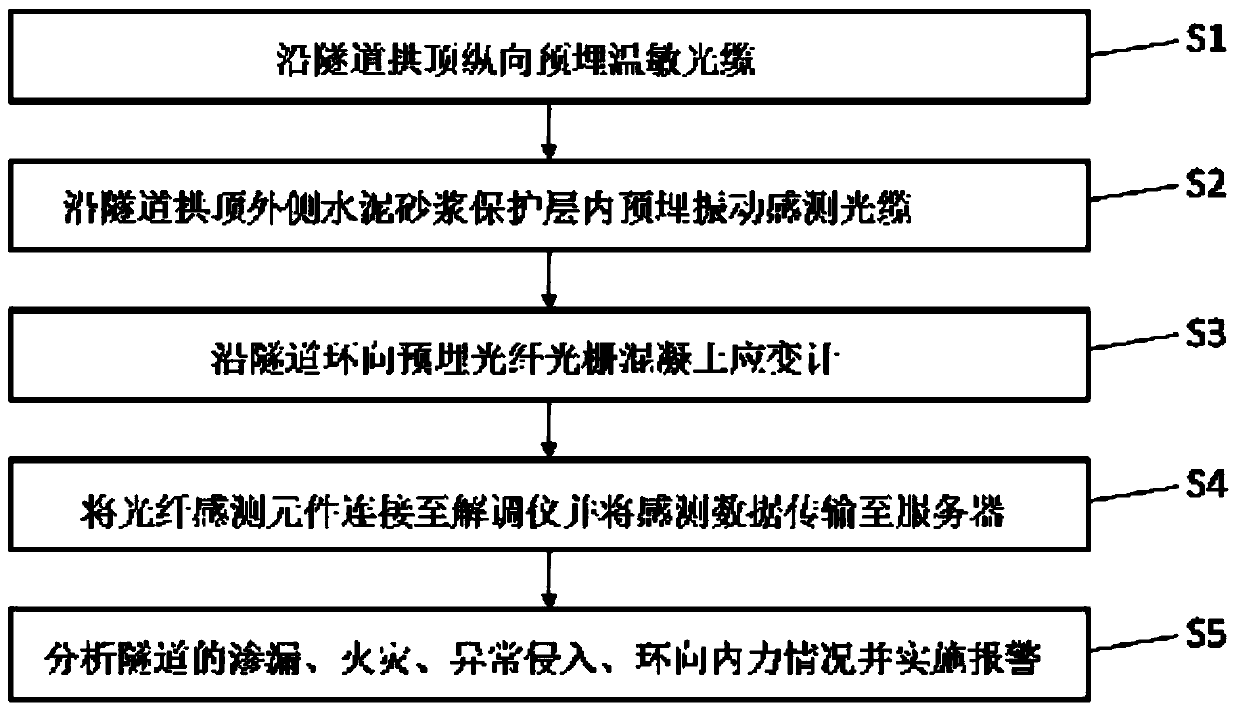

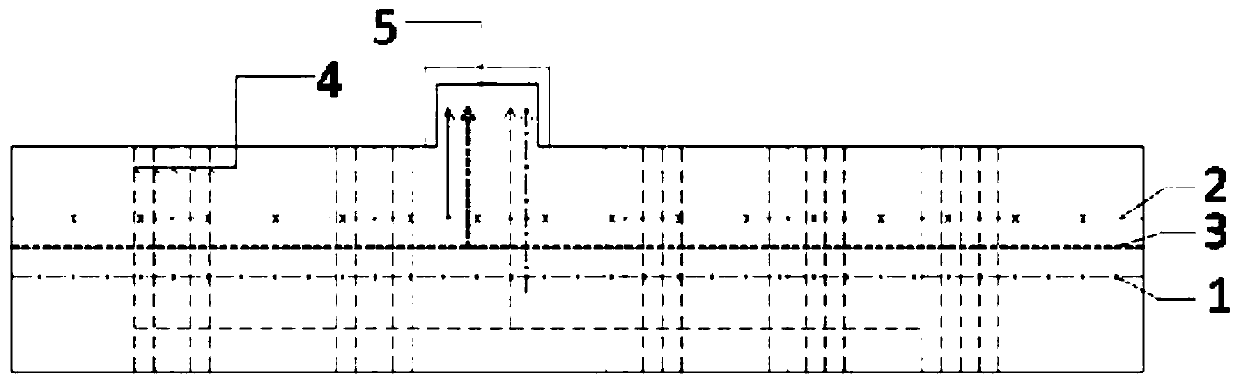

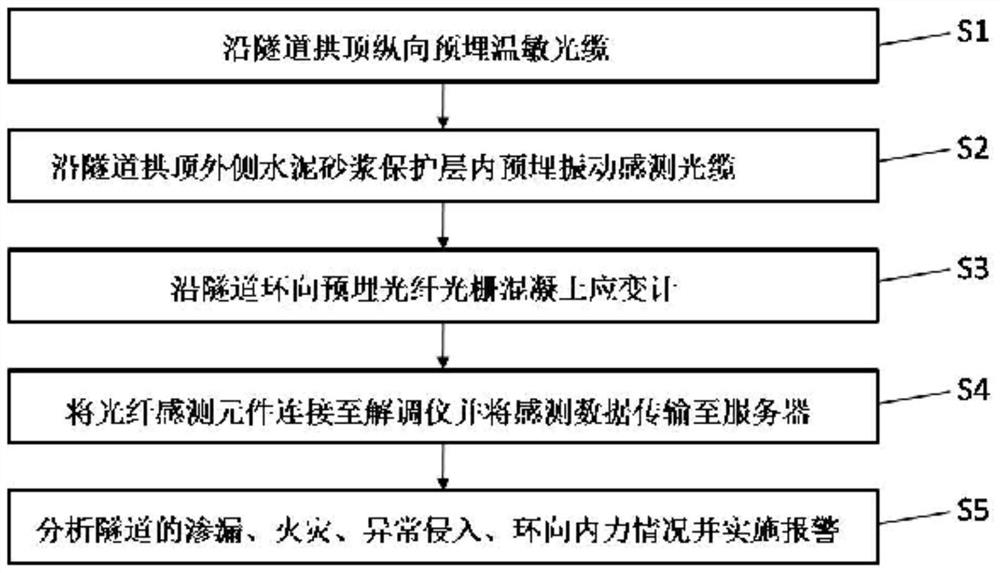

High-speed railway tunnel shape and position sensing method based on buried optical fibers

ActiveCN110455210ADoes not affect normal operationEnsure safe serviceSubsonic/sonic/ultrasonic wave measurementThermometers using physical/chemical changesRailway tunnelHysteresis

The present invention discloses a high-speed railway tunnel shape and position sensing method based on buried optical fibers. The method comprises the following steps: pre-burying a temperature-sensitive optical cable along a longitudinal direction of a tunnel arch; pre-burying a vibration-sensing optical cable along the inner side of a cement mortar protective layer outside the tunnel arch; pre-burying a fiber grating concrete strain gauge along the circumferential direction of the tunnel arch; connecting a fiber sensing component to a demodulator and transmitting sensing data to a server; and analyzing seepage, fire, abnormal intrusion, and a circumferential inner force in the tunnel, and issuing an alarm. According to the method provided by the present invention, the occurrence time andposition of seepage, fire, abnormal intrusion, and other accidents in the tunnel can be accurately sensed and identified in real time, and the whole life cycle of the circumferential inner force in the tunnel can be sensed, so that the problems that the existing tunnel hazard monitoring method relies on the manpower and has hysteresis are solved, and the problems of poor reliability and low dataaccuracy of the existing tunnel internal force monitoring system are solved.

Owner:CHINA RAILWAYS CORPORATION +2

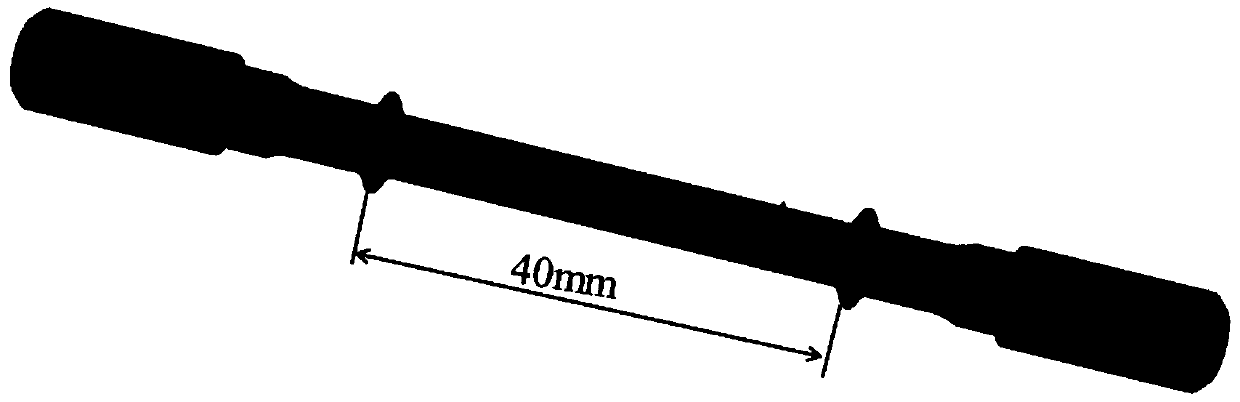

Electron beam welding technology improving aluminum-lithium alloy weld formation and improving joint quality

InactiveCN110653477AEasy to shapeImprove liquidityElectron beam welding apparatusButt jointBeam scanning

The invention discloses an electron beam welding technology improving aluminum-lithium alloy weld formation and improving joint quality. The electron beam welding technology includes the steps that firstly, an aluminum-lithium alloy plate is machined into a welding sample, and the sample is cleaned; secondly, the sample is fixed in a vacuum chamber of an electron beam welding machine, primary welding is conducted, a butt joint manner is adopted, and quasi-circular electron beam scanning wave forms are applied in the welding process; and thirdly, a defocusing electron beam is adopted for conducting modification welding on the surface of an aluminum-lithium alloy electron weld completed in the second step. The electron beam welding technology has the beneficial effects that the technology process is simple, joint weld formation is good, and the joint quality is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

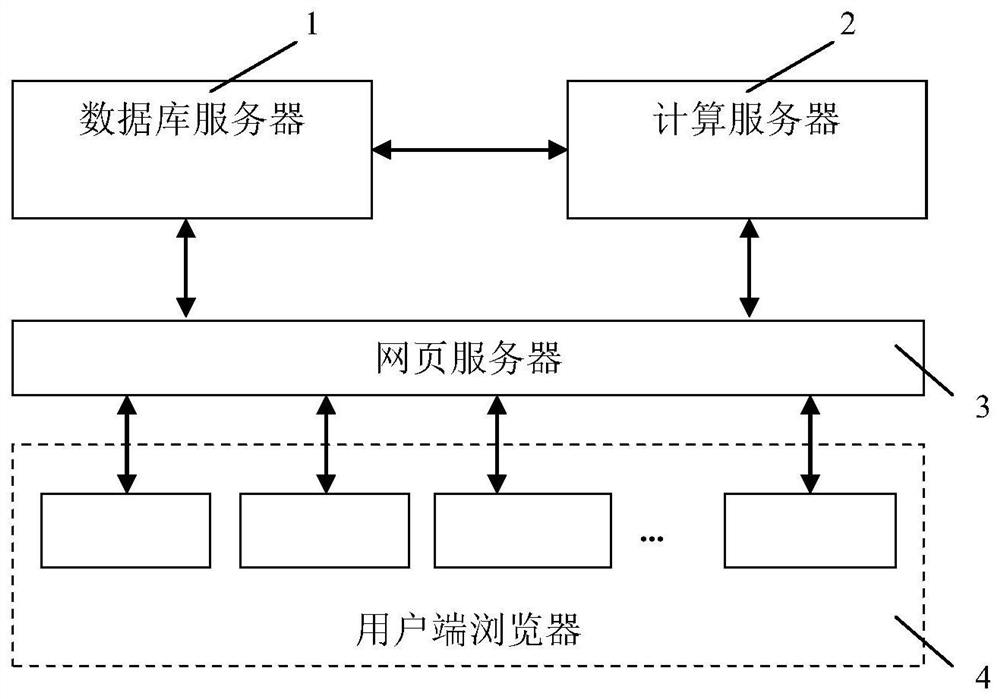

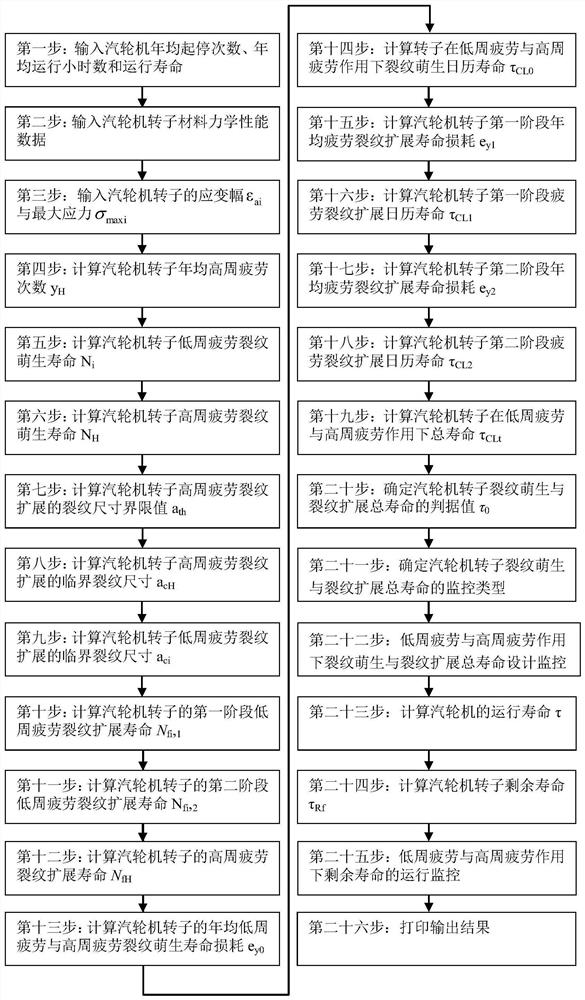

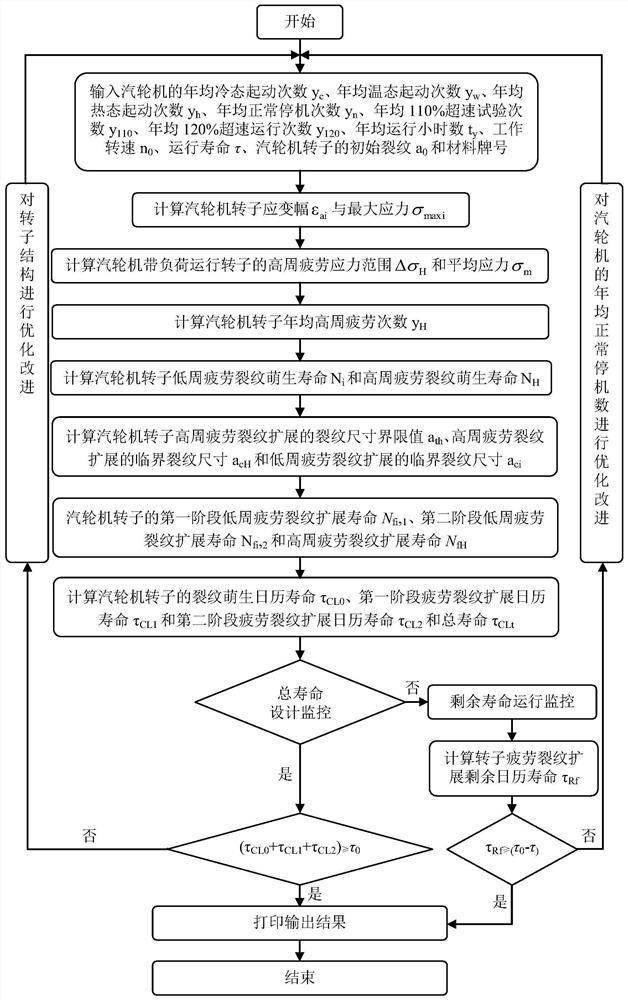

Method for designing and monitoring service life of steam turbine rotor under action low-cycle and high-cycle fatigue

ActiveCN112668111AMonitor Total LifeGuaranteed lifeGeometric CADDesign optimisation/simulationProcess engineeringEngineering

Owner:SHANGHAI POWER EQUIP RES INST

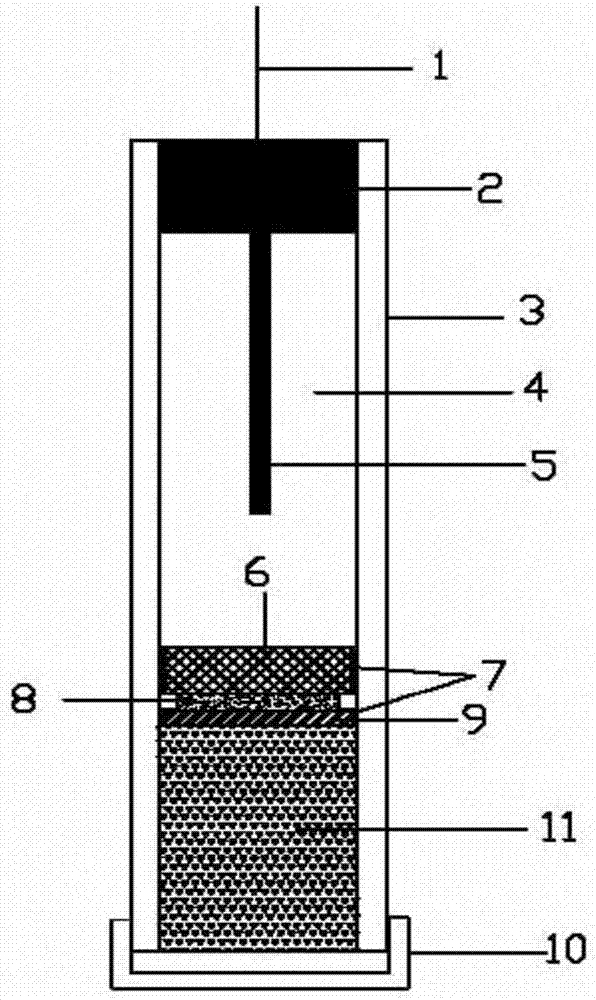

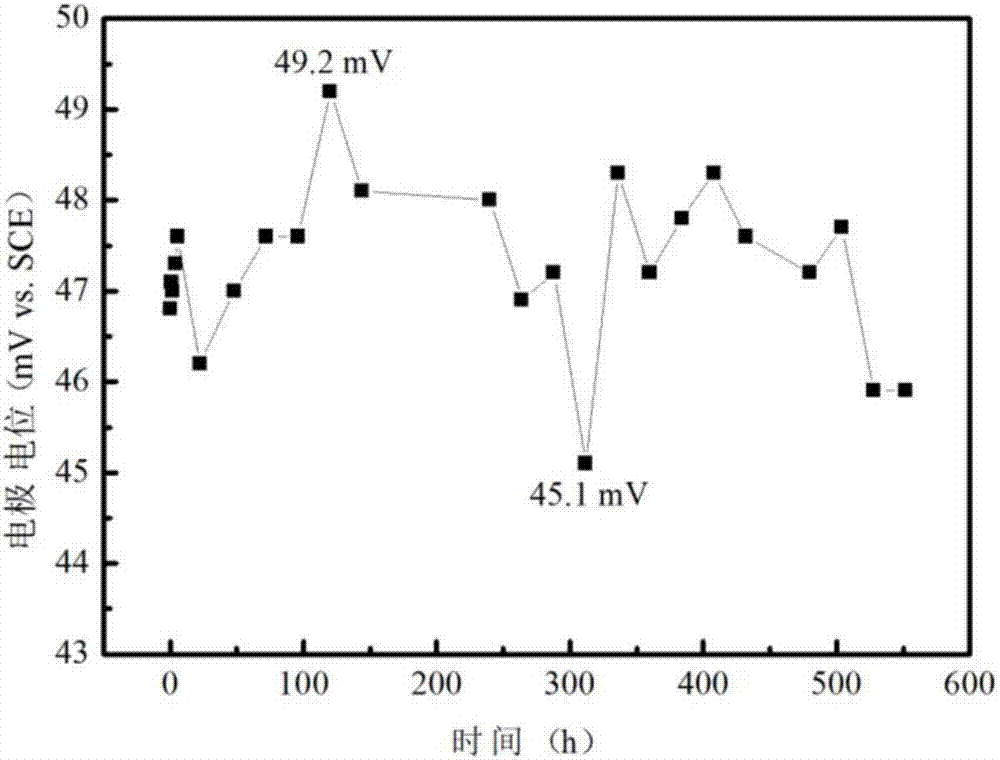

Pre-embedded reference electrode for monitoring corrosion of reinforced concrete, and manufacturing method

ActiveCN106885835AGuaranteed normal transmissionReal-time monitoring of corrosion statusWater resource assessmentMaterial electrochemical variablesRebarElectric cables

The invention discloses a pre-embedded reference electrode for monitoring corrosion of reinforced concrete. The pre-embedded reference electrode comprises a copper cable, a sleeve, a gel electrolyte, an electrode body, a microporous ceramic block, a protective jacket, a post-activation sealing component, a water-absorbing expansion layer and a post-activation sealing component dissolution mortar; the post-activation sealing component is arranged outside a medium transmission end of the existing reference electrode to block the medium transmission between the internal electrolyte and concrete in the earlier period, the water-absorbing expansion layer is filled between the microporous ceramic of the medium transmission end of the reference electrode and the post-activation sealing component so as to fill up the gap after the post-activation sealing component is dissolved, so that the good transmission of medium can be guaranteed. The service life of the reference electrode is remarkably prolonged by adopting a later activation method, and the monitoring on the whole life cycle of the reinforced concrete corrosion state can be realized. The invention further discloses a manufacturing of the pre-embedded reference electrode for monitoring the corrosion of reinforced concrete.

Owner:JIANGSU UNIV OF SCI & TECH +1

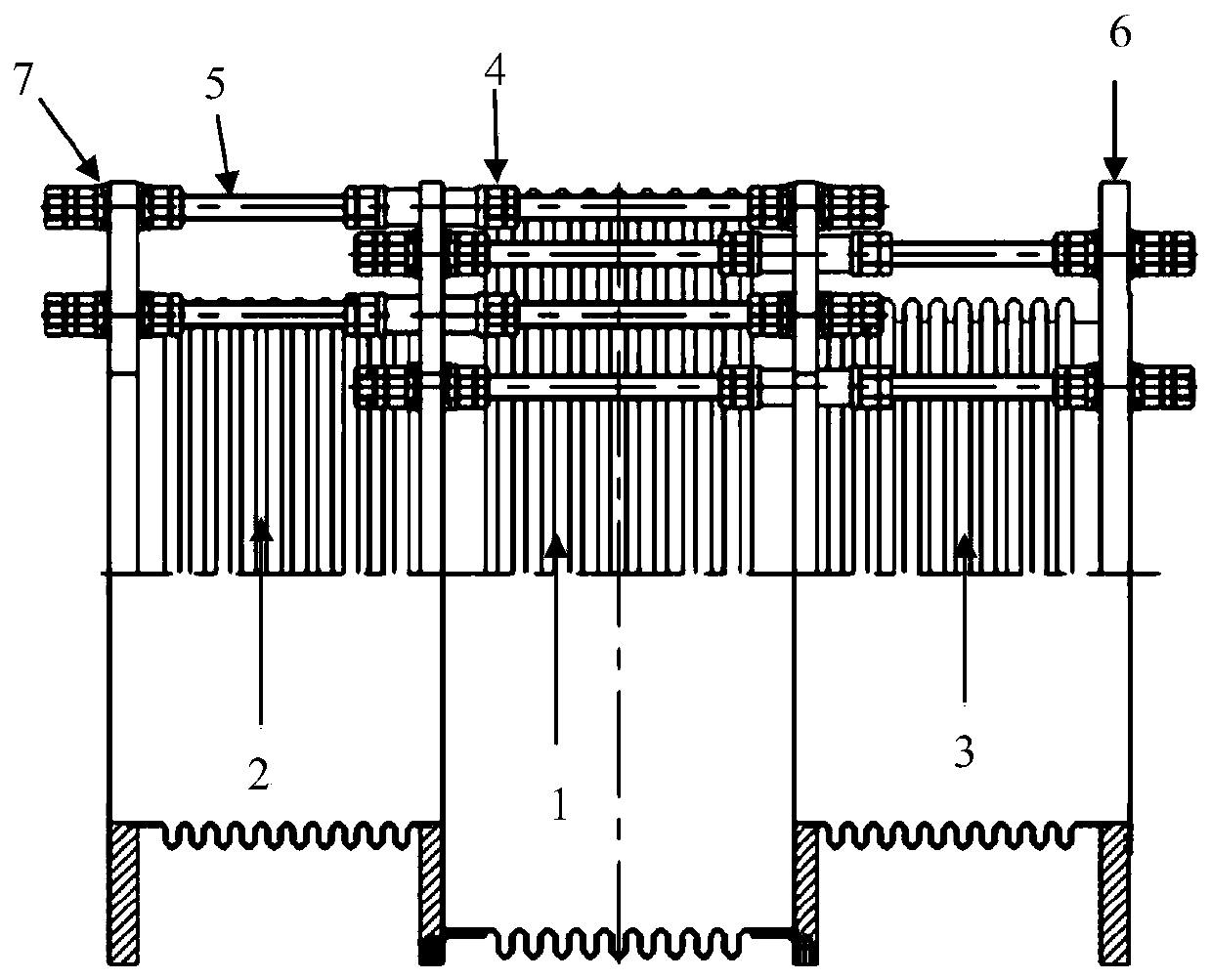

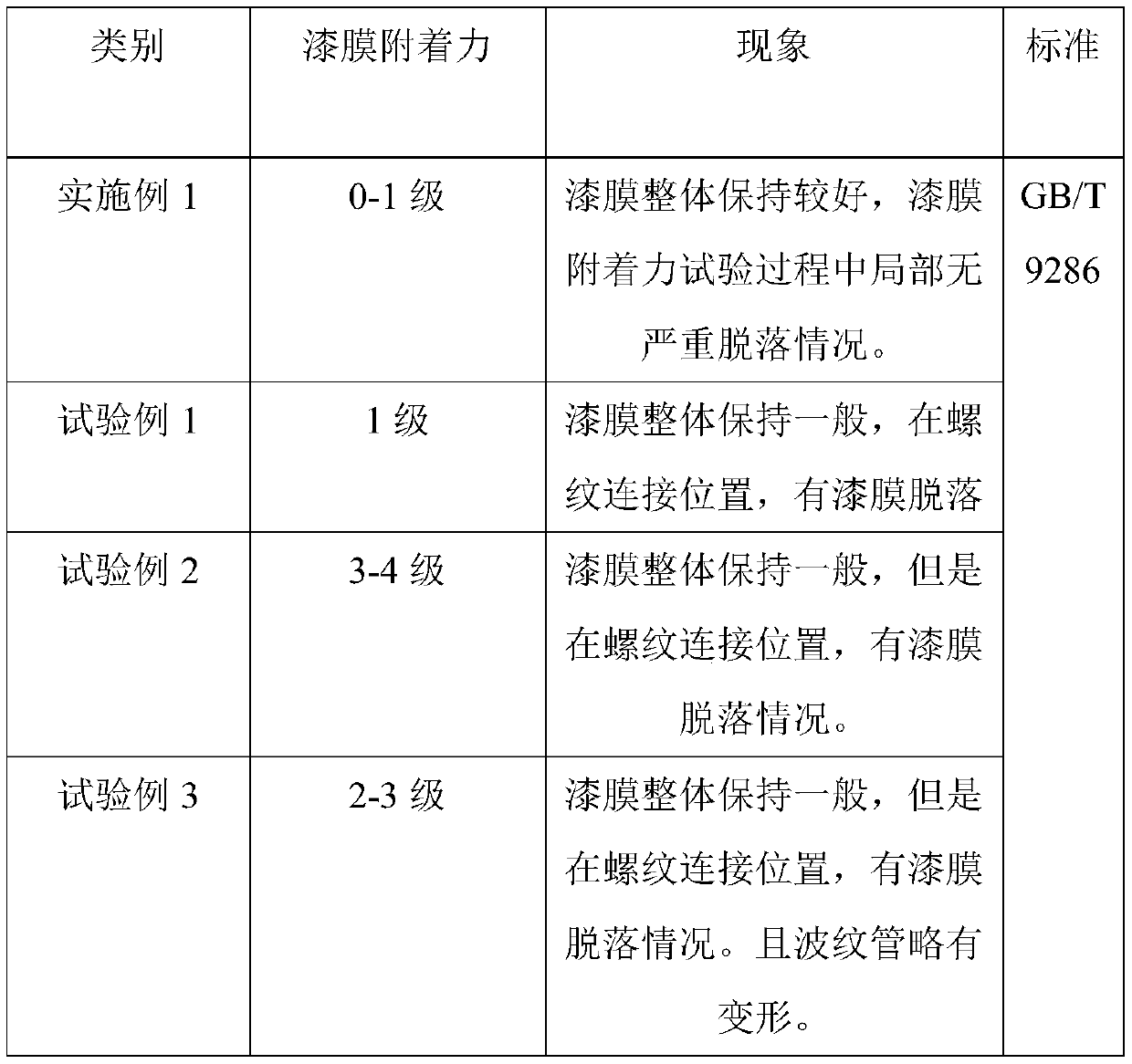

Coating method of corrugated pipe assembly for high-voltage switch

PendingCN110193455AImprove pass rateEnsure safe servicePretreated surfacesCoatingsBinding forcePower grid

The invention relates to a coating method of a corrugated pipe assembly for a high-voltage switch, and belongs to the technical field of coating. The method comprises the steps that gasoline is used for cleaning the corrugated pipe assembly, then, heating and baking are performed under the temperature of 45-55 DEG C, then, gasoline is used for performing key local cleaning and heating baking underthe temperature of 45-55 DEG C on the corrugated pipe assembly, oil stains at gaps of parts are thoroughly cleaned away, oil stains are volatilized or carbonized, the method can improve the cleaningefficiency and quality of the corrugated pipe assembly, binding force of a film is improved, according to the coating product obtained through the method, the yield is greatly increased, the coating adhesive force reaches level 0-1, and the safety service of the high-voltage switch and safety operation of a power grid are ensured.

Owner:PINGGAO GRP +2

Ultrasonic positioning method of SiC fiber reinforced Ti-base composite material ring piece core

ActiveCN104820020AImprove processing qualityEnsure safe serviceAnalysing solids using sonic/ultrasonic/infrasonic wavesAlloySic fiber

The invention discloses an ultrasonic positioning method of a SiC fiber reinforced Ti-base composite material ring piece core, and belongs to the technical field of preparation and detection of a composite material. A SiC fiber reinforced Ti-base composite material ring piece has a sandwiched structure and consists of a composite material ring core and a peripheral Ti alloy outer sleeve. By utilizing a water leaching focusing ultrasonic detection method, firstly the accurate sound speed of ultrasonic waves in the composite material ring core and the Ti alloy outer sleeve is acquired by virtue of a measurement-aided calculation method, and then a distance from the surface of the ring piece to the core and the contour size of the ring piece core are measured by utilizing the sound speed, so that the ring piece core can be accurately positioned. By adopting the method, important significance on improving the machining quality of the SiC fiber reinforced Ti-base composite material ring piece and guaranteeing the safety application can be achieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

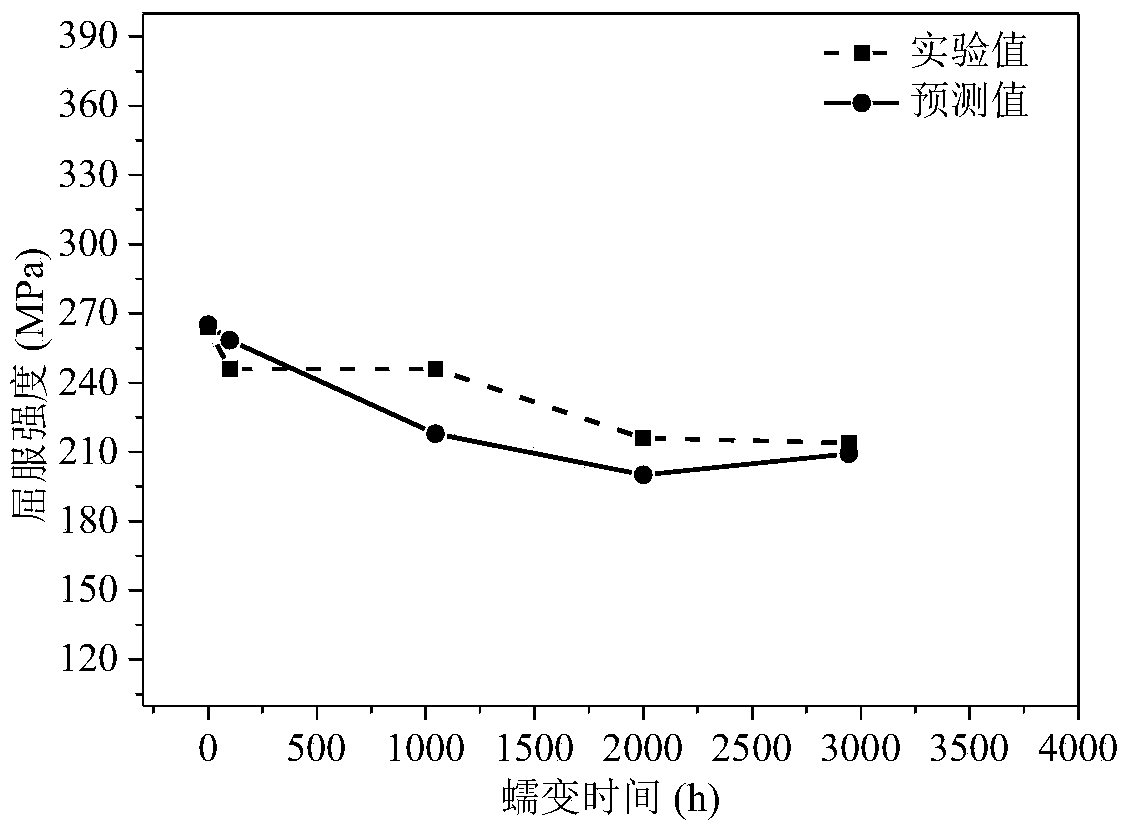

A high temperature strength prediction method for martensitic steel based on microstructure degradation

ActiveCN109002628AEnsure safe serviceDesign optimisation/simulationSpecial data processing applicationsUltimate tensile strengthService condition

The invention discloses a high-temperature strength prediction method of martensitic steel / ferrite steel based on microstructure degradation, namely a high-temperature strength prediction model basedon microstructure degradation under high-temperature service conditions. Based on the contribution of different strengthening mechanisms to the yield strength, the key microstructure parameters of thematerial under high temperature service condition are introduced to calculate the high temperature yield strength with high temperature service damage state. The high-temperature strength predictionmethod based on microstructure degradation established by the invention can accurately predict the high-temperature strength of the high-temperature structure in long-term high-temperature service. Byincorporating the degradation of high temperature strength caused by microstructure degradation into the life assessment of high temperature structure, the service safety of high temperature structure can be further ensured, and the loss of life and property can be reduced.

Owner:TIANJIN UNIV

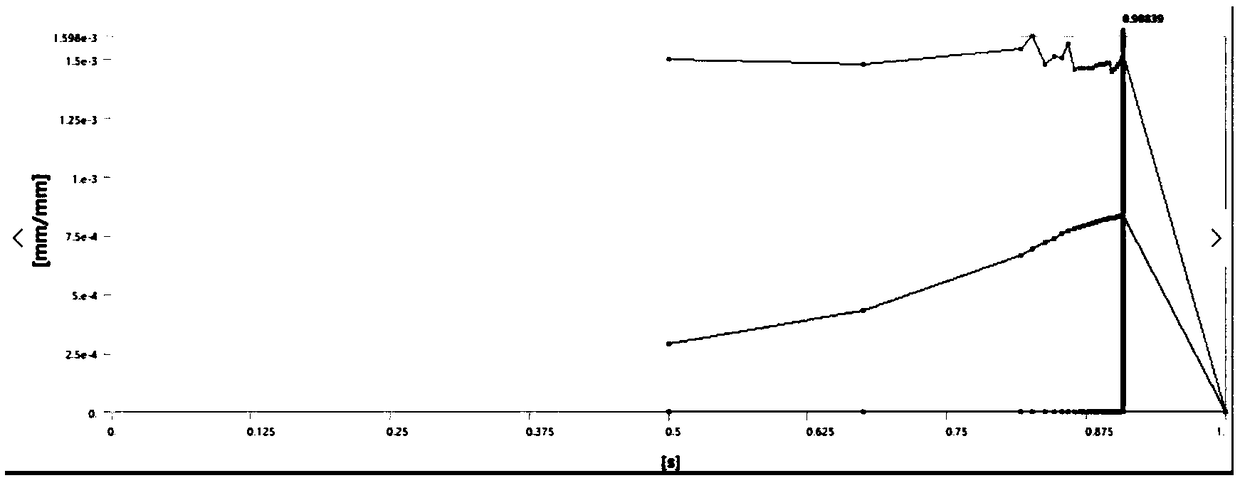

Monitoring sensor for accumulated fatigue damage of mechanical structure under normal load distribution rule, design method and monitoring method

ActiveCN111426460AEnsure safe serviceGeometric CADMachine part testingFatigue damageStructural fatigue

The invention provides a monitoring sensor for accumulated fatigue damage of mechanical structure under normal load distribution rule, a design method and a monitoring method, which belong to the technical field of structure fatigue monitoring. An installation pin of the fatigue damage monitoring sensor is used for bearing stress on the surface of the mechanical structure; two strain amplificationbridges are used for amplifying the average strain of the surface of the measured structure at the position covered by a stretching arm at different multiplying powers, so as to guarantee that the fatigue life foil works within the effective strain amplitude range; through a structure cumulative fatigue damage monitoring model, when the structure serves under the load effect complying with the normal distribution rule, the cumulative fatigue damage of the mechanical structure can be obtained according to the resistance cumulant of the double-fatigue-life foil. Safe service of mechanical partsis ensured, and accidents are prevented.

Owner:DALIAN UNIV OF TECH

Reinforced sealing flat cap intensity checking method

ActiveCN108763686ASolve the confusion of designing such componentsEnsure safe serviceGeometric CADDesign optimisation/simulationDesign standardEconomic benefits

The invention discloses a reinforced sealing flat cap intensity checking method, belongs to the technical field of pressure container flat cap intensity design, and aims at solving the problem that the flat cap design standard degree is bad, and reinforced sealing bottle caps designed by designers are short in service life as no reinforced sealing flat cap intensity check method exists in the prior art. The method comprises the following steps of: calculating a thickness of a non-reinforced flat cap according to a flange design method of a pressure container design standard specification; 2, determining a thickness, which is 0.55 time of the thickness of a reinforced flat cap, of the non-reinforced flat cap; and 3, checking structural intensity of dangerous sections of the flat caps. The reinforced sealing flat cap intensity checking method is capable of solving the confusion of designing such type of parts by engineering designers, can be feasibly applied into practical design activities, and has obvious economic benefit along with the increase of outer ring diameters of flat caps.

Owner:HARBIN ELECTRIC CO LTD

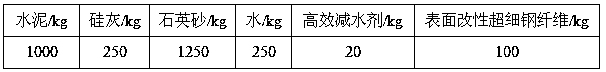

A surface-modified ultra-fine steel fiber reinforced high-impedance ultra-high performance concrete and its preparation method

The invention discloses surface-modified ultrafine steel fiber reinforced high-impedance ultrahigh-performance concrete and a preparation method thereof, and belongs to the technical field of buildingmaterials. The ultrahigh-performance concrete comprises the following components in parts by mass: 50-300 parts of surface-modified ultrafine steel fiber, 500-1500 parts of cement, 50-500 parts of amineral admixture, 1000-1800 parts of fine aggregate, 5-40 parts of a chemical admixture and 150-650 parts of water. The preparation method comprises the following steps: preparing a nanometer silicondioxide modifier; performing surface modification on ultrafine steel fiber; stirring and curing concrete. Through modification of growing SiO2 on the surface of the ultrafine steel fiber, morphologically, the surface roughness is improved and a friction coefficient between the fiber and a matrix is increased, and chemically, by virtue of high volcanic ash activity of nanometer SiO2, secondary hydration is performed on the nanometer SiO2 and a cement hydration product Ca(OH)2 to produce calcium silicate hydrate gel C-S-H so as to improve a weak interfacial region; the flexural strength of thesurface-modified ultrafine steel fiber reinforced high-impedance ultrahigh-performance concrete reaches 25MPa or above, and the electrical resistivity thereof reaches 20,000 ohm.cm or above.

Owner:HARBIN INST OF TECH

A high-speed rail tunnel shape and position sensing method based on buried optical fiber

ActiveCN110455210BDoes not affect normal operationEnsure safe serviceSubsonic/sonic/ultrasonic wave measurementThermometers using physical/chemical changesRailway tunnelDisease monitoring

The invention discloses a shape and position sensing method of a high-speed railway tunnel based on an embedded optical fiber, which comprises the following steps: pre-embed a temperature-sensitive optical cable along the longitudinal direction of the tunnel vault, and pre-embed a vibration sensor in the cement mortar protective layer outside the tunnel vault. Optical cables, pre-embedded fiber grating concrete strain gauges along the tunnel ring, connecting the optical fiber sensing elements to the demodulator and transmitting the sensing data to the server, analyzing the leakage, fire, abnormal intrusion, ring internal force of the tunnel and implementing Call the police. The present invention can sense and identify the occurrence time and location of events such as tunnel leakage, fire, and abnormal intrusion in real time and accurately, and can sense the inner force of the tunnel ring in the whole life cycle, which solves the problem that existing tunnel disease monitoring methods rely on It solves the problems of poor reliability and low data accuracy of the existing tunnel internal force monitoring system.

Owner:CHINA RAILWAYS CORPORATION +2

A rapid repair method of cement emulsified asphalt mortar for unit slab ballastless track

ActiveCN104480815BGuaranteed smoothnessGuaranteed operational safetyRailway track constructionComing outCement mortar

The invention relates to a method for rapidly repairing cement emulsified asphalt mortar interface connection damage of a unit slab ballastless track; the method mainly comprises the steps of cleaning, sealing, setting of grouting openings, interface connection damage grouting and edging treatment; the specific steps are as follows: firstly, cleaning dust and impurities around a mortar interface connection damage; secondly sealing the interface connection damage area, setting the grouting openings and placing a dial indicator at four corners of a track slab in a to-be-repaired area; thirdly, connecting a dual-component self-mixing grouting machine with a pressure grouting hose, and injecting a dual-component grouting material to the grouting openings in sequence; after the mortar comes out of a grouting opening having the spacing of more than the width of the track slab with the next grouting openings, turning to the next grouting opening to grout continuously till the whole cement emulsified asphalt mortar seam area is fully grouted; and finally, cutting the grouting hose, polishing sealed materials to finish the repairing. The method has the characteristics of simple and rapid process, high repairing efficiency and capability of realizing rapid repairing within skylight time and is applicable to repairing the cement emulsified asphalt mortar seams of the unit slab ballastless track.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

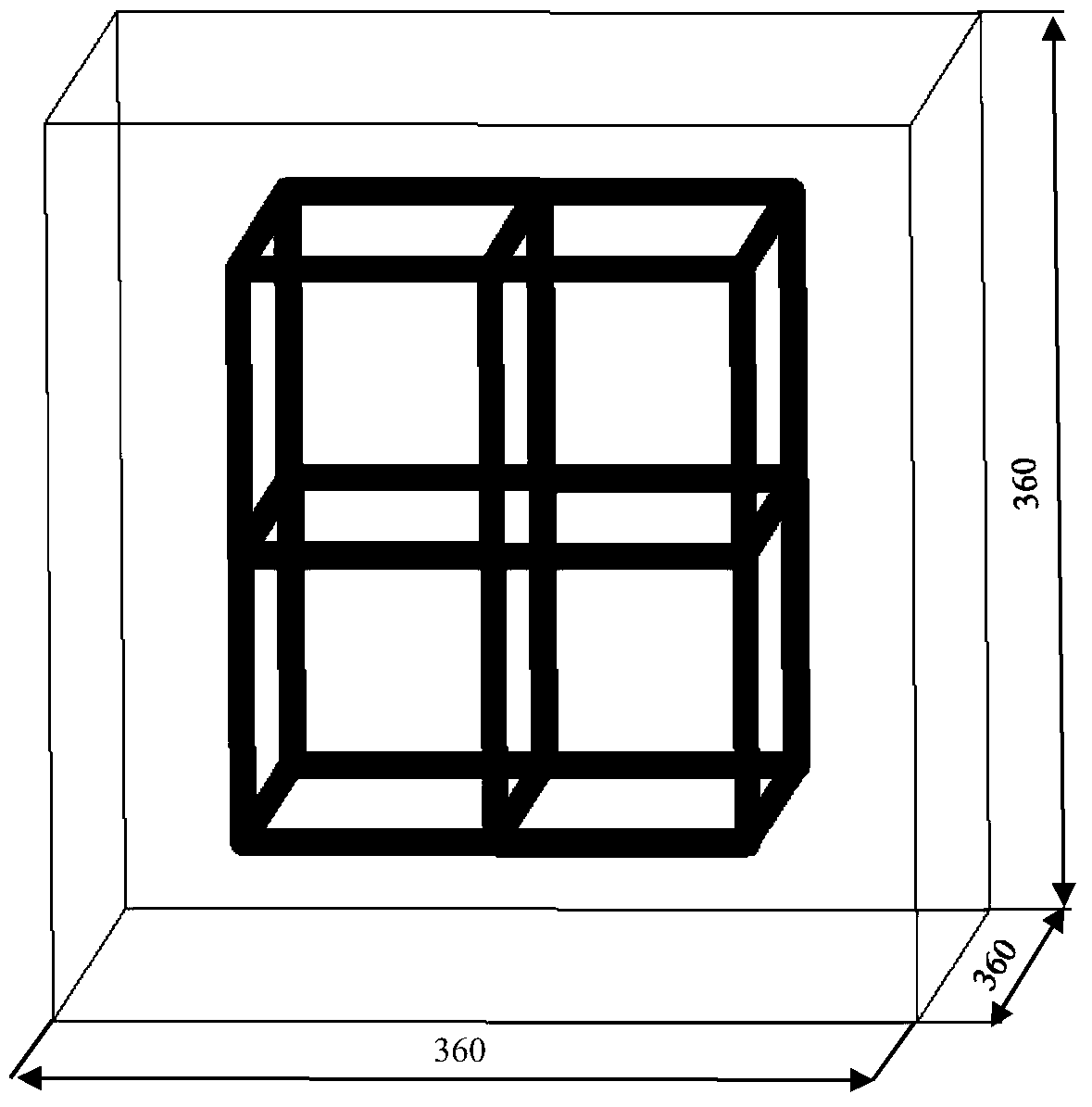

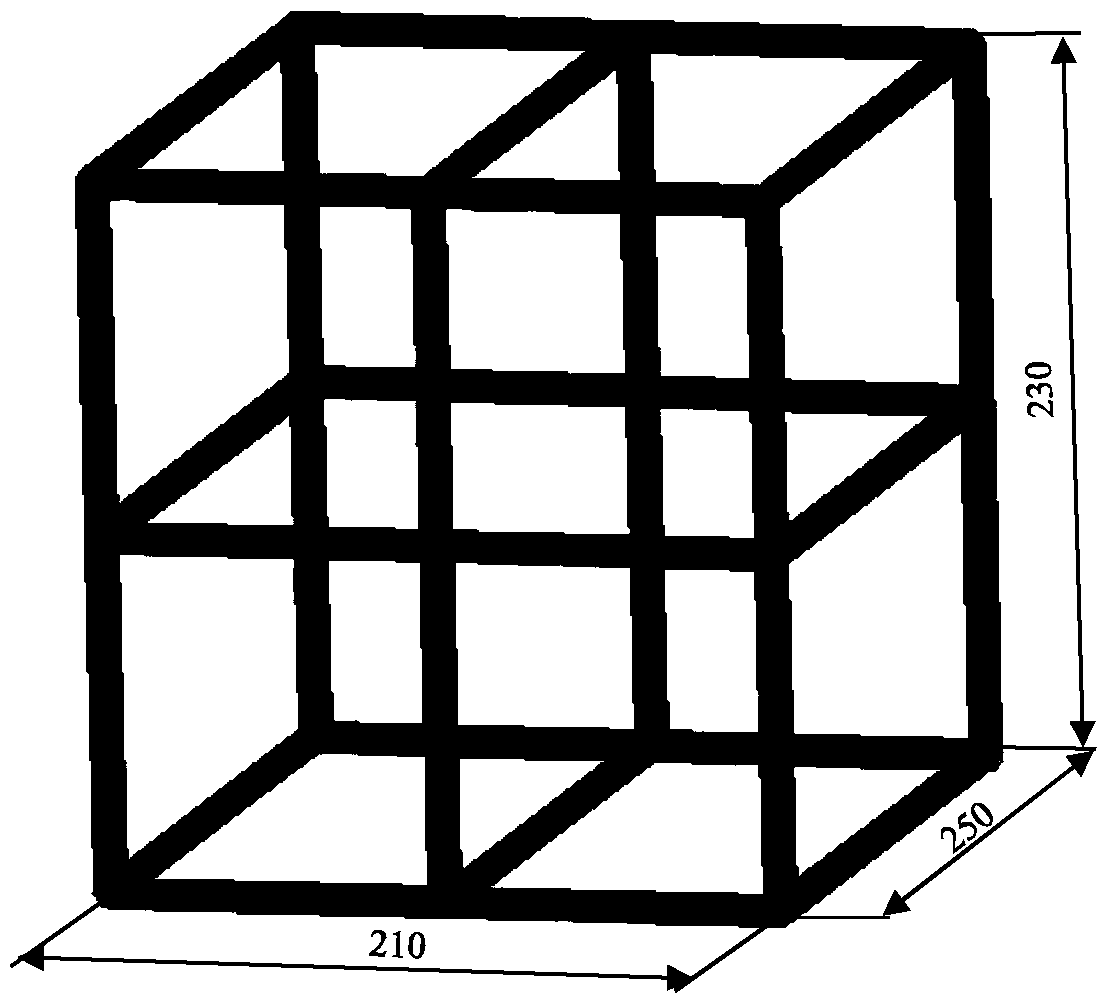

A marine test method for concrete with built-in steel cage

ActiveCN105675477BEnsure safe serviceWeather/light/corrosion resistanceSurface oceanExperimental methods

The invention relates to the field of durability of reinforced concrete and aims to provide a marine experimental method of steel reinforcement cage built-in concrete. According to the method, a blocky concrete test piece is placed at a testing position of a sea tidal zone, and the concrete test piece is regularly detected; a steel reinforcement cage with a three-dimensional cage structure is built in the concrete test piece; the selected testing position of the sea tidal zone should have sea tidal action, that is to say, it is ensured that the time for the concrete test piece to be contacted with seawater within a day should be 8-16h. By selecting a sea tidal environment, a real work environment is provided for the test piece. By selecting the concrete test piece, safe service of the test piece in the testing process is guaranteed. By the built-in steel reinforcement cage, an internal material composition environment of reinforced concrete is more truly shown.

Owner:ZHEJIANG UNIV

A regional overall treatment method for water seepage and cracks in open-cut tunnels of high-speed railways

ActiveCN109653777BEven groutingEnsure safe serviceUnderground chambersTunnel liningWater leakageDrill hole

The invention discloses a regional overall treatment method for leaking water and cracks in open-cut tunnels of high-speed railways. The grout forms a new waterproof film; checks for water leakage after grouting; cuts off the exposed grouting nozzle and seals it. The present invention aims at the characteristics of high-speed railway open-cut tunnels, especially for complex tunnel situations where there are many leaking water cracks and a wide distribution range, and the sealing of one crack will easily cause the leakage of surrounding unplugged cracks. The high-strength high-speed railway open-cut tunnel leakage and crack regional overall treatment method adopts the whole section as a whole ring grouting, and the grouting holes are evenly arranged in each ring, which can realize uniform grouting at the vault, arch waist and side walls, etc. Through regional overall improvement, a new waterproof system will be formed to provide guarantee for the safe service of the tunnel structure.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

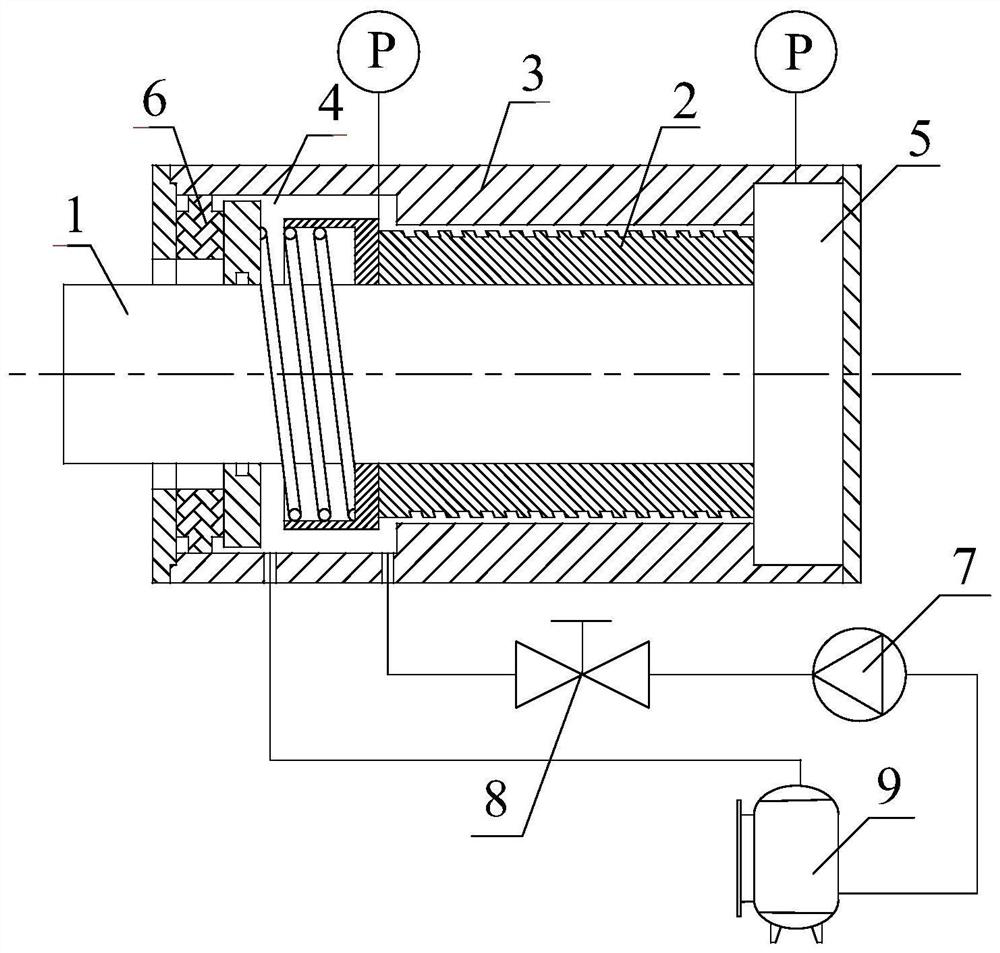

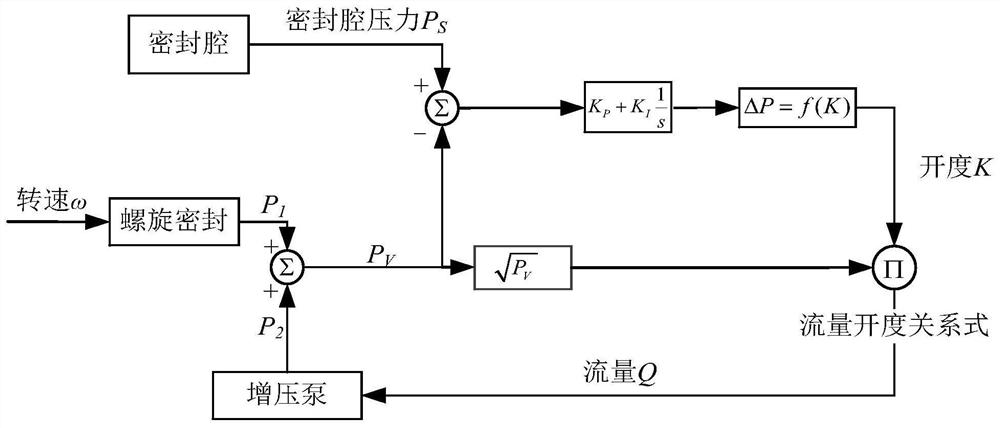

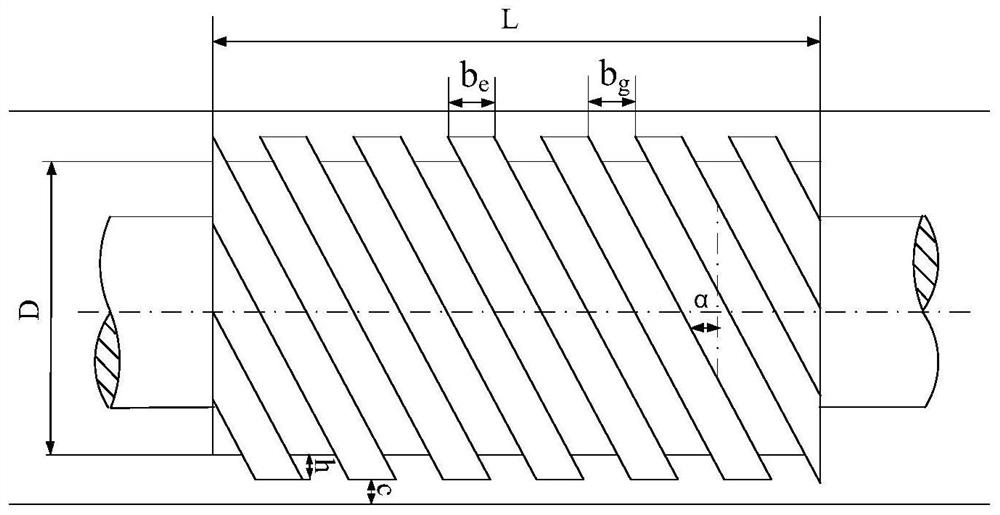

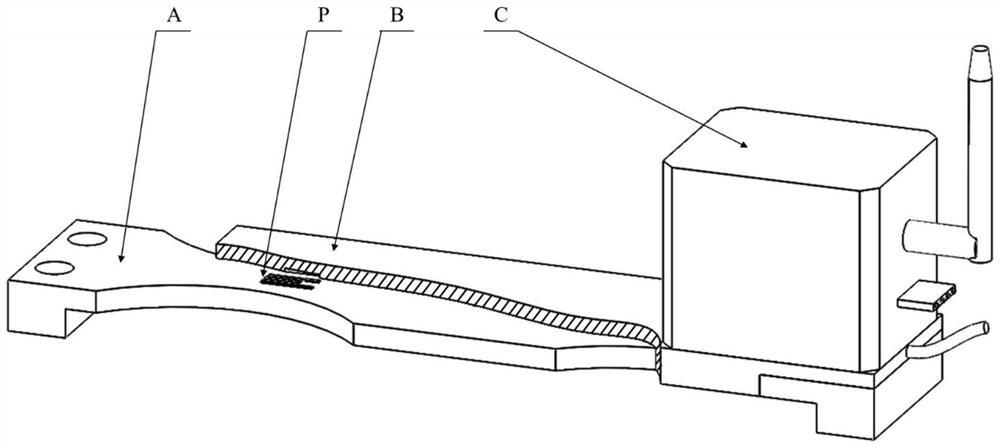

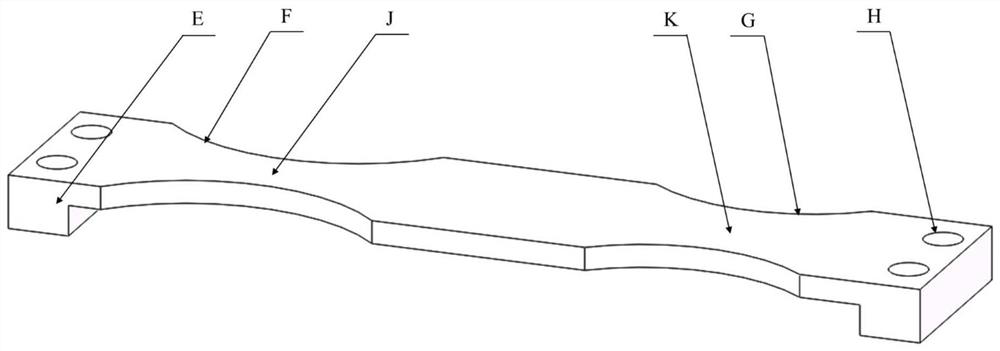

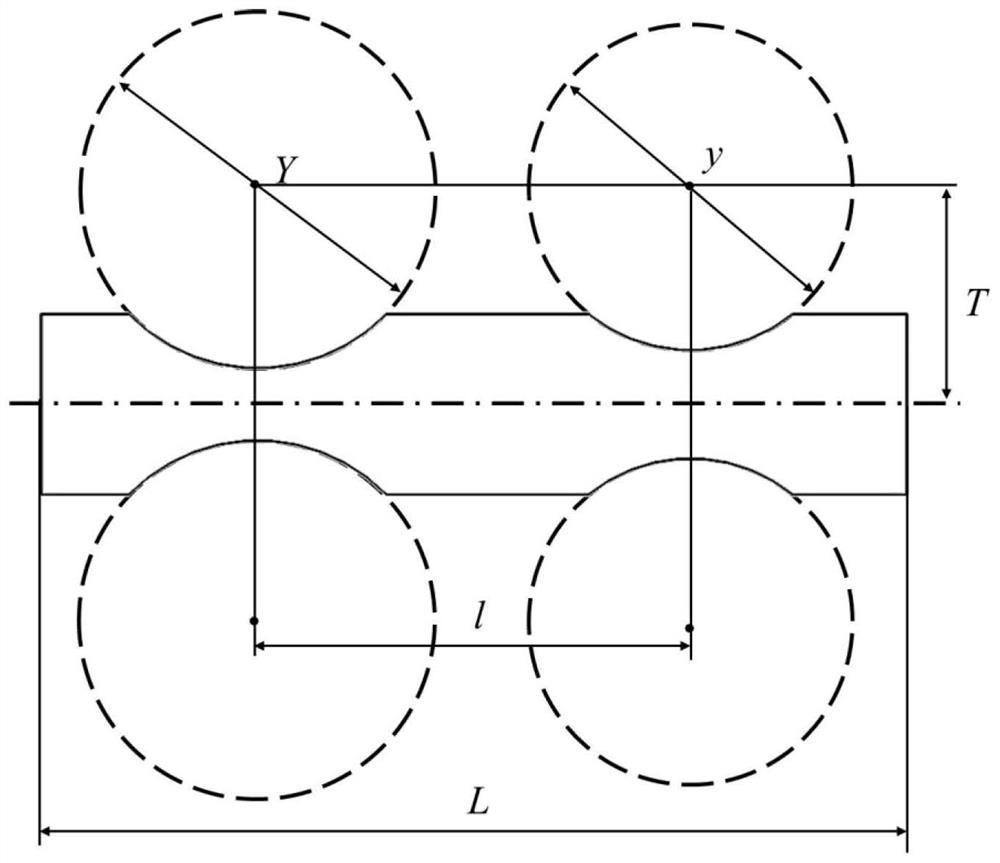

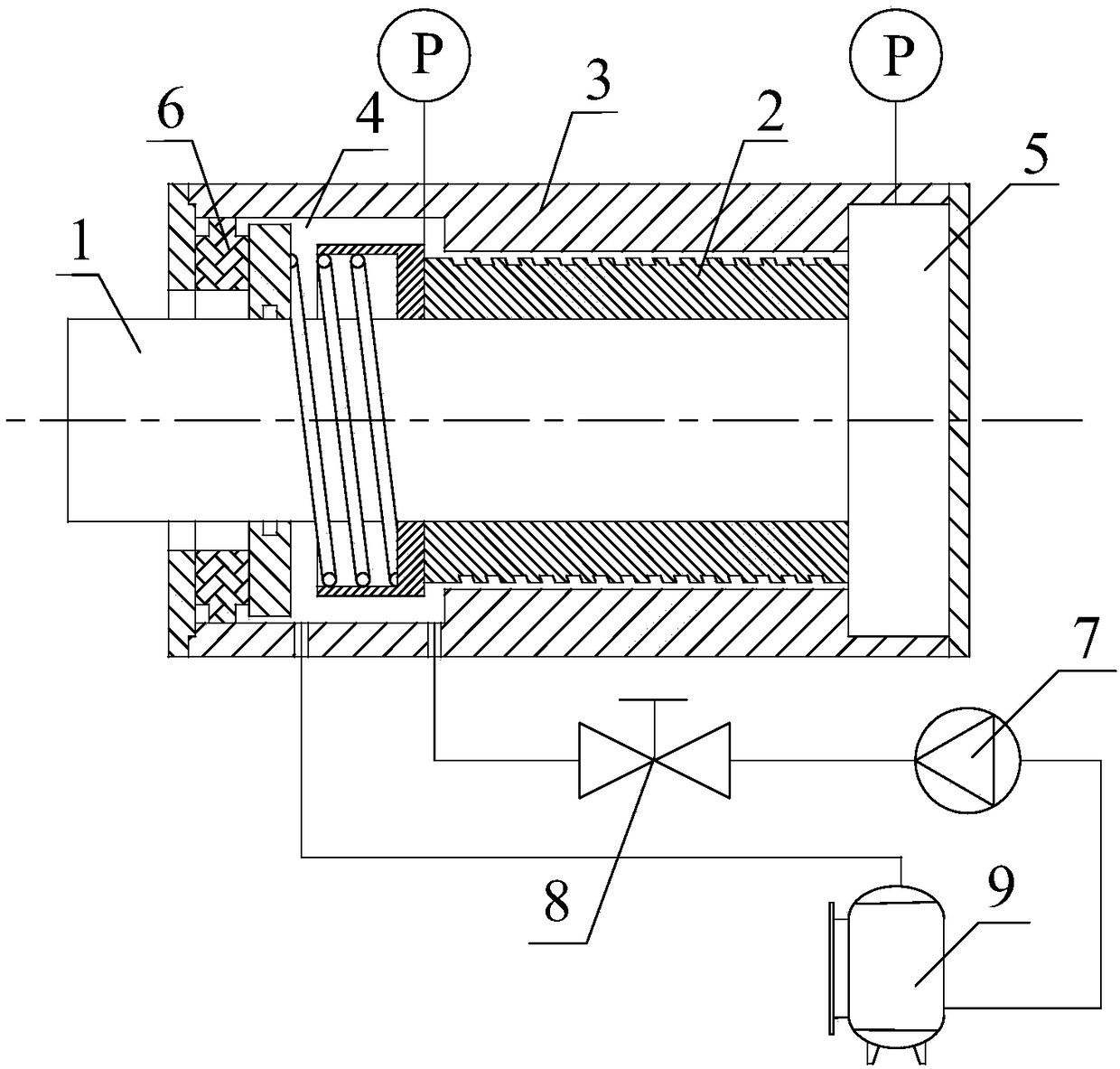

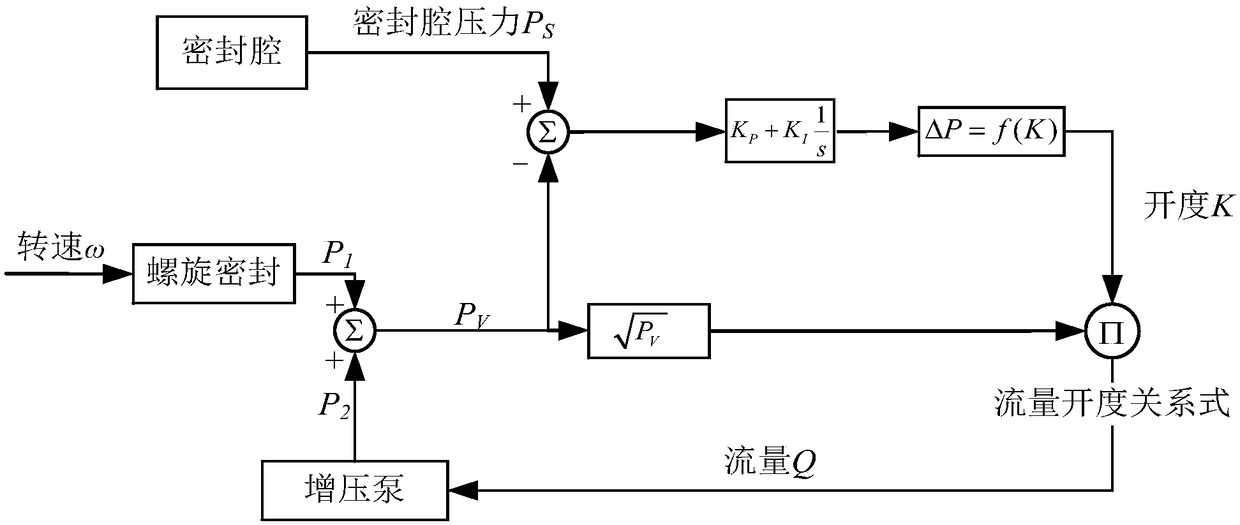

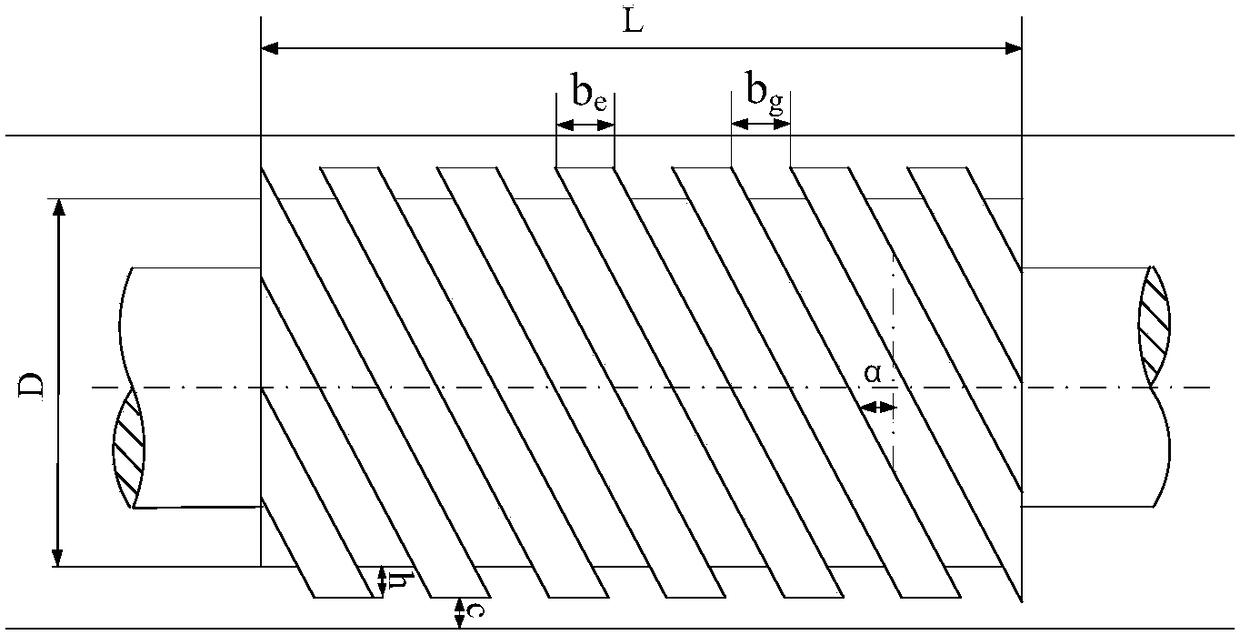

A Turbine Shaft End Sealing Device Applied in Karina Power Cycle System

ActiveCN108457707BWill not corrodeAvoid corrosionLeakage preventionMachines/enginesPower cycleTurbine

The invention provides a turbine shaft-end seal device applied to a Kalina power circulating system. The device comprises a spiral seal system and a water seal system, wherein the spiral seal system comprises a spiral shaft sleeve, a stationary sleeve, a leak collecting cavity, a seal cavity and a mechanical seal; the spiral shaft sleeve is embedded onto the main shaft of a Kalina power circulating turbine, the stationary sleeve and the spiral shaft sleeve are arranged in a spaced manner at the same end of the main shaft in a sleeving manner to form the spiral seal, the seal end of the stationary shaft and the end part of the main shaft form a sealed cavity, the open end of the stationary sleeve and the main shaft form a cavity as the leak collecting cavity, and the mechanical seal arranged between the stationary sleeve and the main shaft is located in the leak collecting cavity; when the main shaft rotates, the spiral shaft sleeve rotates to pressurize the seal cavity; the water sealsystem comprises a pressurizing pump, an adjusting valve and a water tank; the input end of the water tank communicates to the leak collecting cavity while the output end of the water tank communicates to the tail end of the gap between he spiral shaft sleeve and the stationary sleeve successively through a pressurizing pump and the adjusting valve. Through three seals: the mechanical seal, the water seal and the spiral seal, the problem of corrosion caused by contact of ammonia-enriched steam and the mechanical structure is avoided.

Owner:XI AN JIAOTONG UNIV

A sensor, design method and monitoring method for cumulative fatigue damage monitoring of mechanical structures under normal load distribution

ActiveCN111426460BEnsure safe serviceGeometric CADMachine part testingFatigue damageStructural fatigue

The invention provides a mechanical structure accumulative fatigue damage monitoring sensor, a design method and a monitoring method under the normal load distribution law, and belongs to the technical field of structural fatigue monitoring. The mounting feet of the fatigue damage monitoring sensor are used to withstand the stress on the surface of the mechanical structure, and the average strain of the surface of the measured structure covered by the stretching arm is amplified by different magnifications through two strain amplification bridges to ensure the effective strain amplitude of the fatigue life foil Work within the scope; through the structural cumulative fatigue damage monitoring model, when the structure is in service under the load that obeys the normal distribution law, the cumulative fatigue damage of the mechanical structure can be obtained according to the cumulative resistance of the double fatigue life foil to ensure the safety of mechanical parts Serve to prevent accidents from happening.

Owner:DALIAN UNIV OF TECH

A quick repair material for joints between slabs of crts Ⅱ slab ballastless track

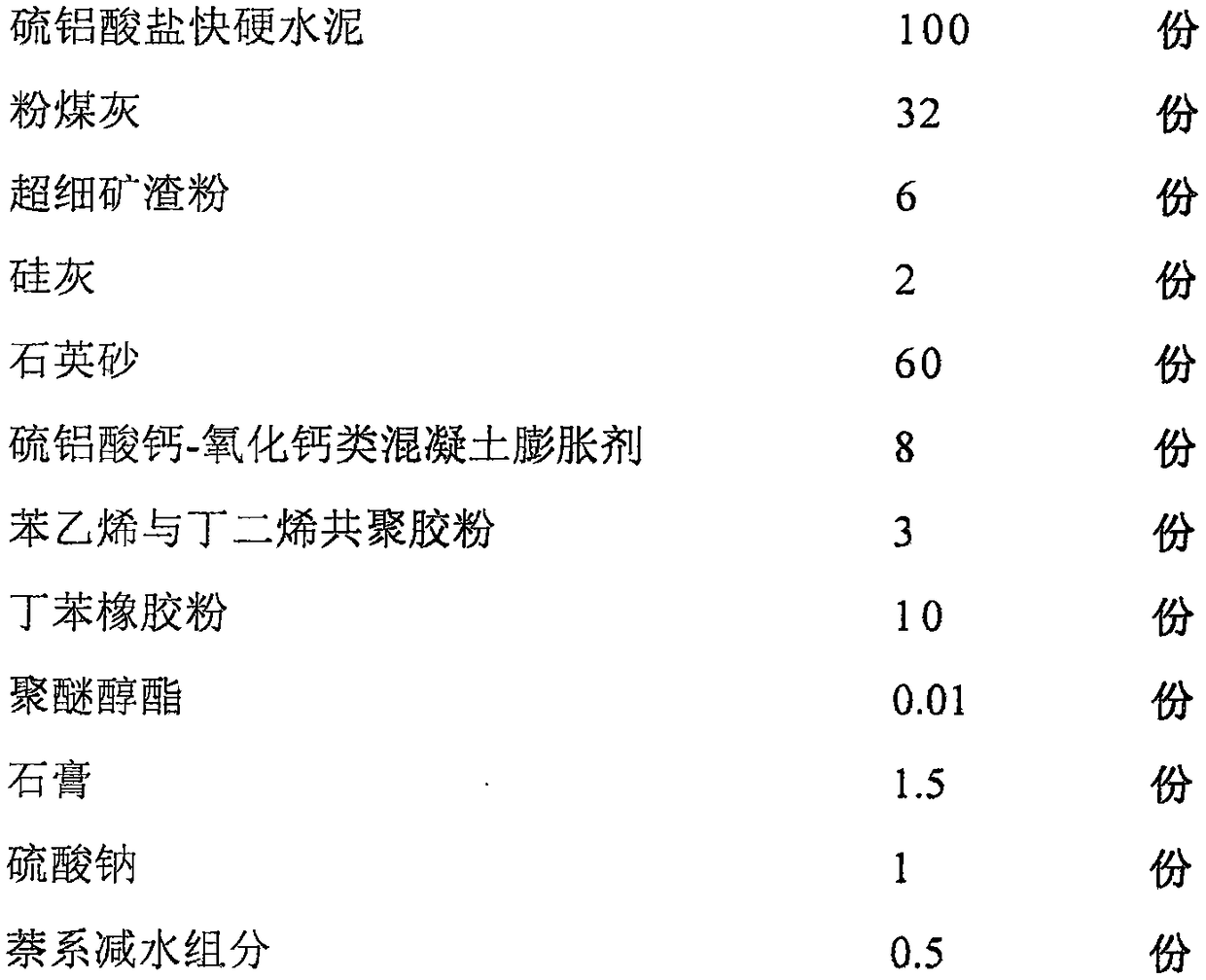

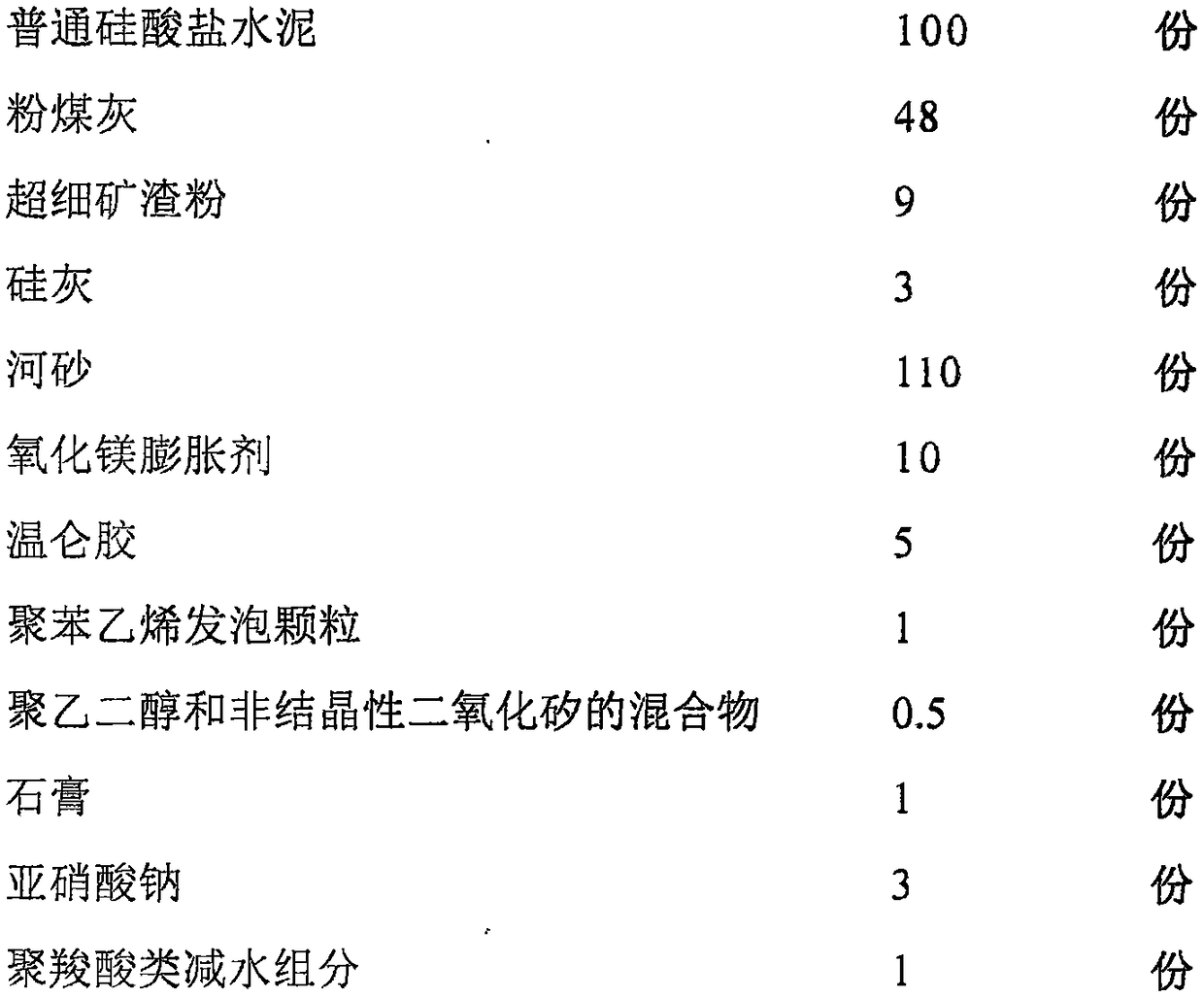

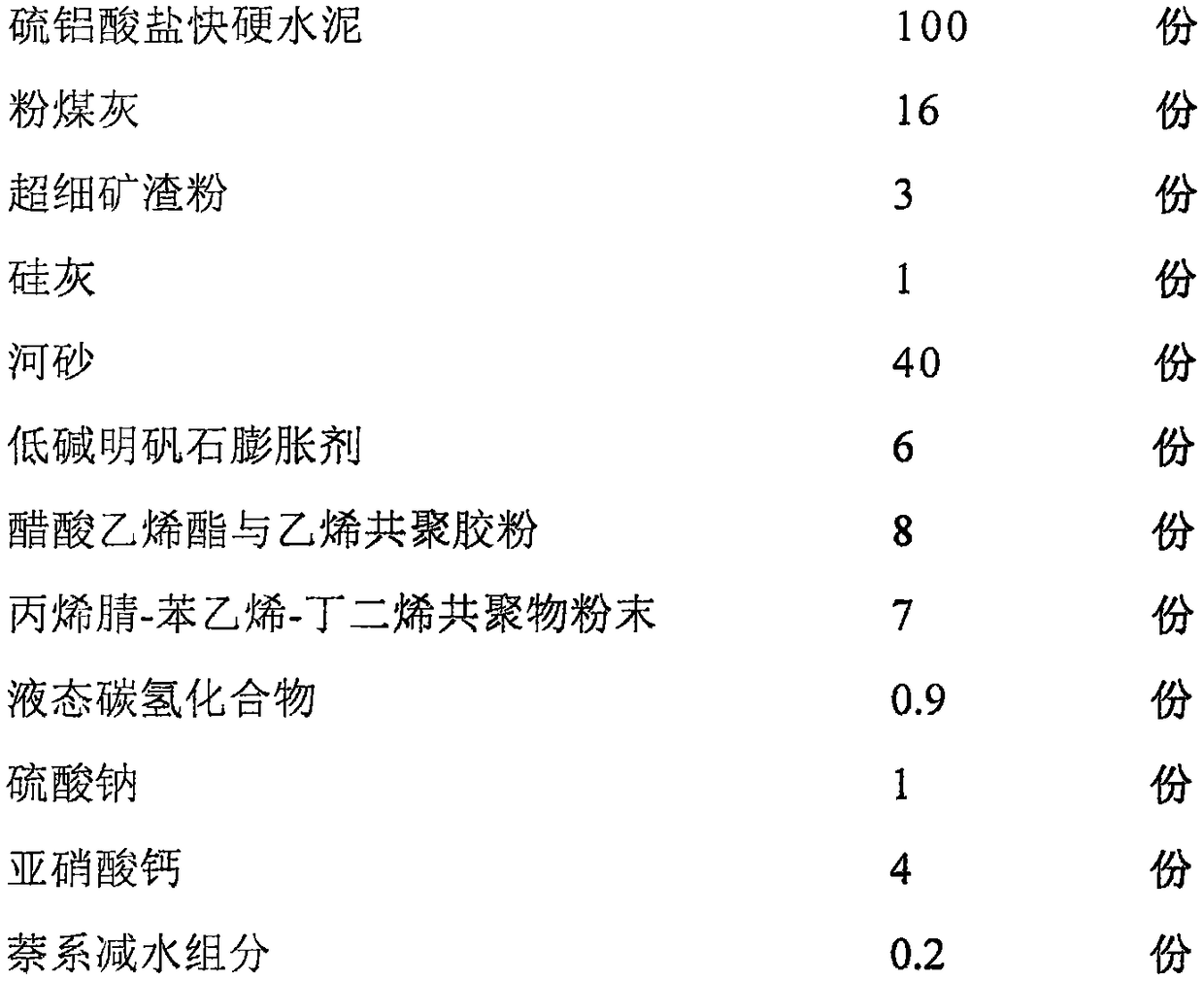

The invention relates to a rapid repairing material of a seam between CRTS II shaping plate ballastless track boards. The material comprises, by mass, 100 parts of cement, 16-48 parts of fly ash, 3-9 parts of ultrafine slag powder, 1-3 parts of silica fume, 40-110 parts of fine aggregates, 6-12 parts of a slight expansion component, 1-8 parts of a polymerization bonding component, 1-10 parts of a modulus adjusting component, 0.01-2 parts of a powder antifoaming agent, 0.5-5 parts of a hardening acceleration component and 0.2-1 part of a water reduction component. The material has the characteristics of simple workability, high bonding strength, high strength, rapid setting, low modulus and high durability, is suitable for rapidly repairing the seam between CRTS II shaping plate ballastless track boards, and is also suitable for rapidly repairing other similar structures.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

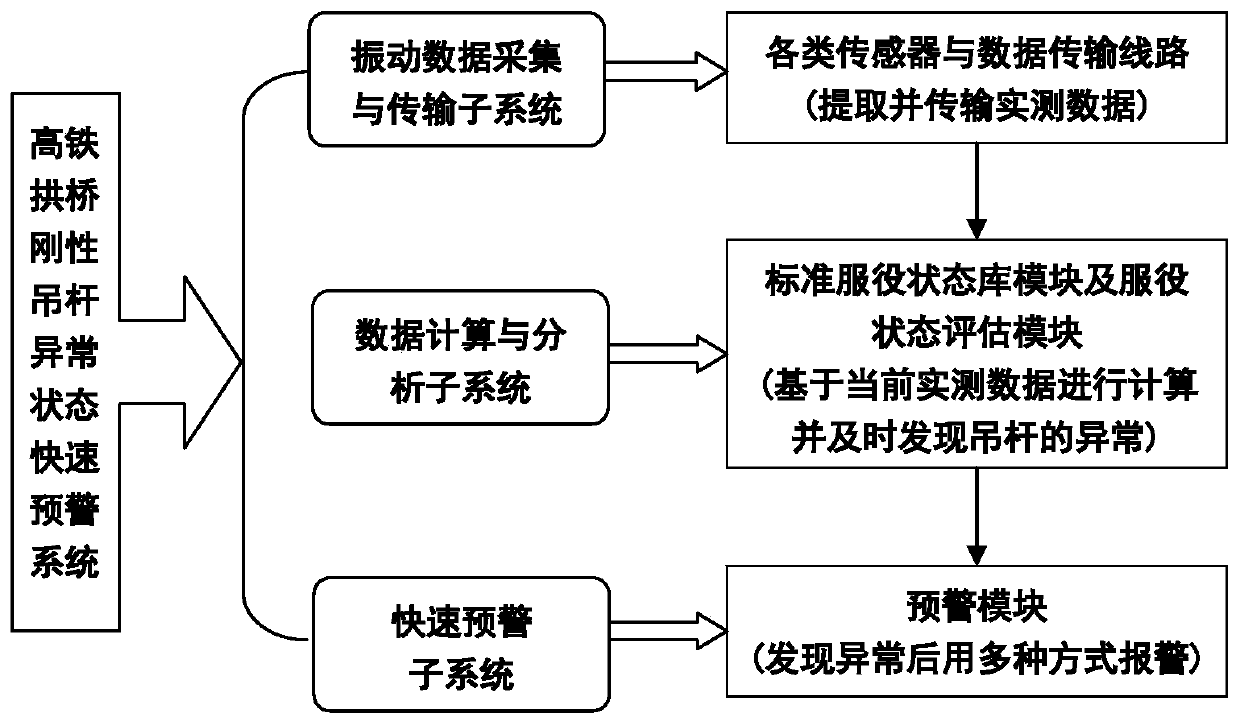

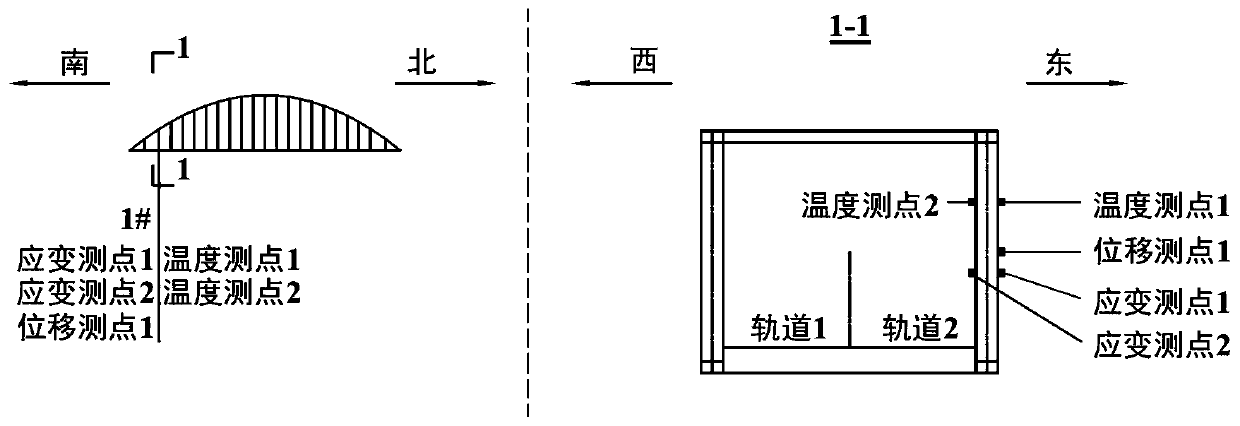

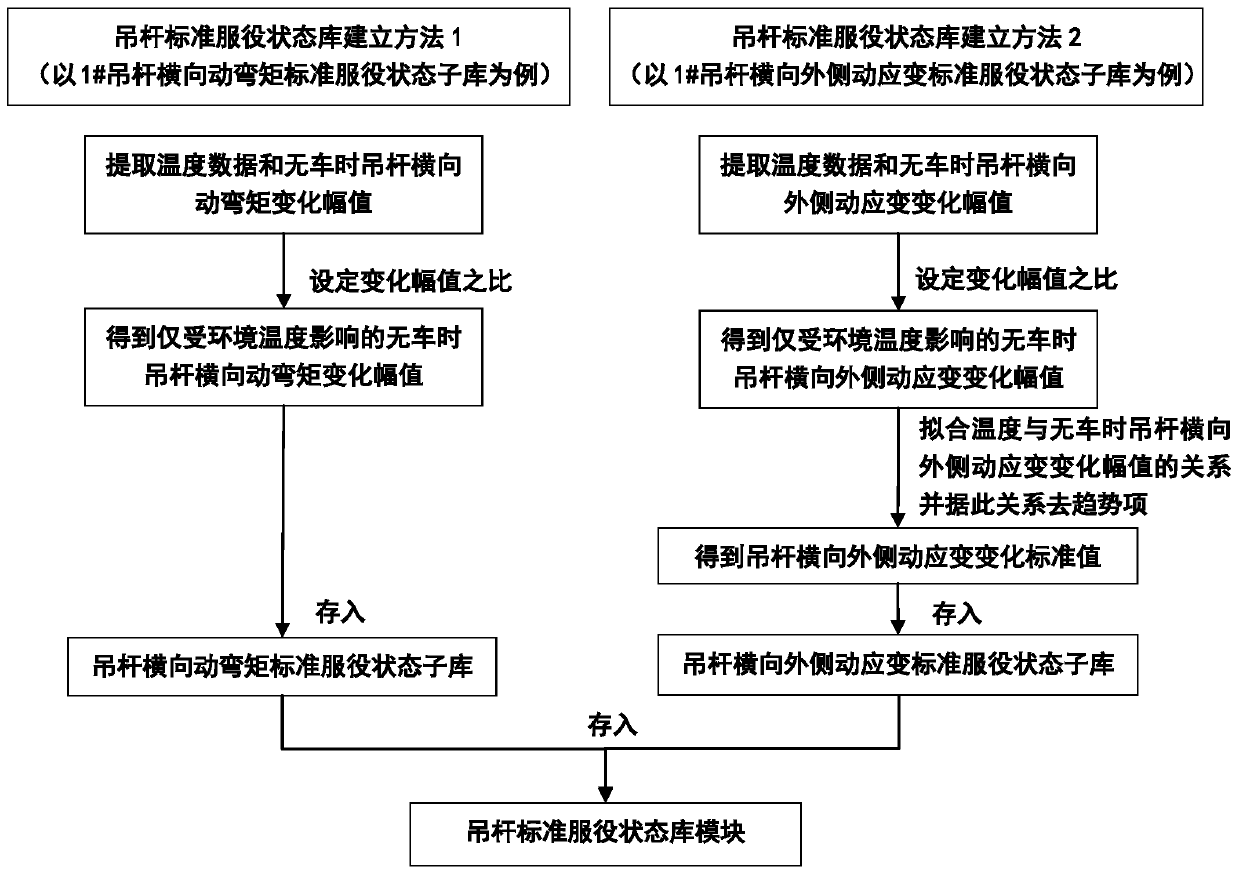

Rapid early warning system and method for abnormal state of rigid suspender of high-speed rail arch bridge

ActiveCN107220755BEnsure safe serviceEnsure driving safetyBridge structural detailsResourcesEarly warning systemSimulation

The invention provides a rapid high-speed train arch bridge rigid suspension rod abnormal state early warning system and a method thereof. The system comprises a vibration data acquisition and transmission subsystem, a data calculation and analysis subsystem and a rapid early warning subsystem, wherein the vibration data acquisition and transmission subsystem comprises a sensor and data transmission lines mounted on a high-speed train arch bridge structure, the data calculation and analysis subsystem is used for carrying out calculation and analysis on actually-measured suspension rod data based on different service state evaluation indexes, comparing the analysis result with an early warning threshold or an early warning envelope of each standard service state sub database established through utilizing actually-measured data of a suspension rod in a normal service state and rapidly evaluating a service state of the suspension rod, after the suspension rod is discovered to be in an abnormal state, the rapid early warning subsystem alarms to management personnel through modes of starting an alarm lamp, a handset alarm telephone or a short message. The system is advantaged in that the high-speed train arch bridge rigid suspension rod service state can be monitored, abnormity can be timely discovered, alarm can be emitted, and the system is of great significance to high-speed train arch bridge rigid suspension rod safe service and high-speed train safe operation.

Owner:DALIAN UNIV OF TECH

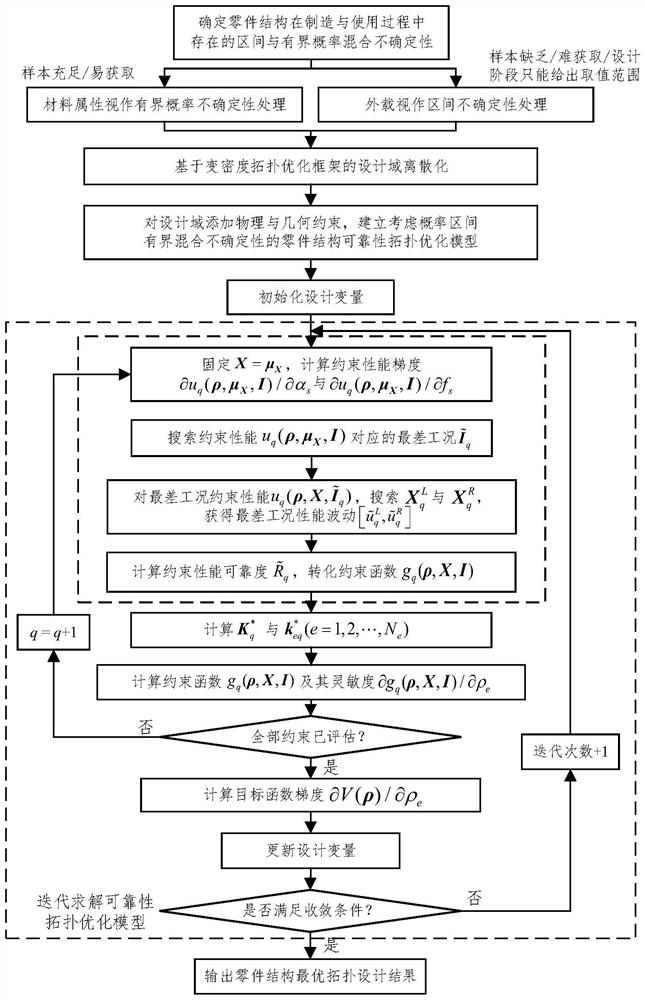

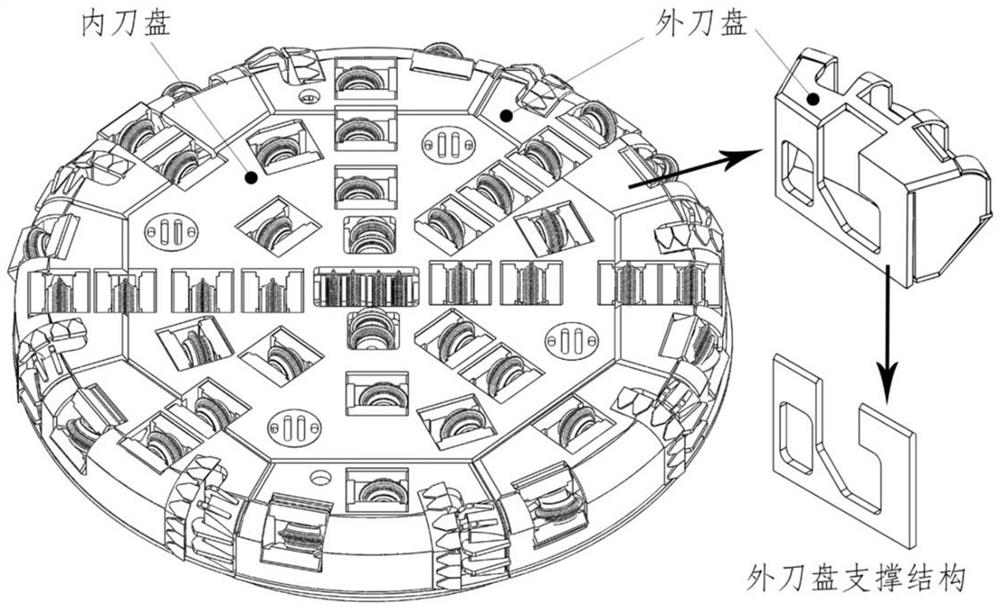

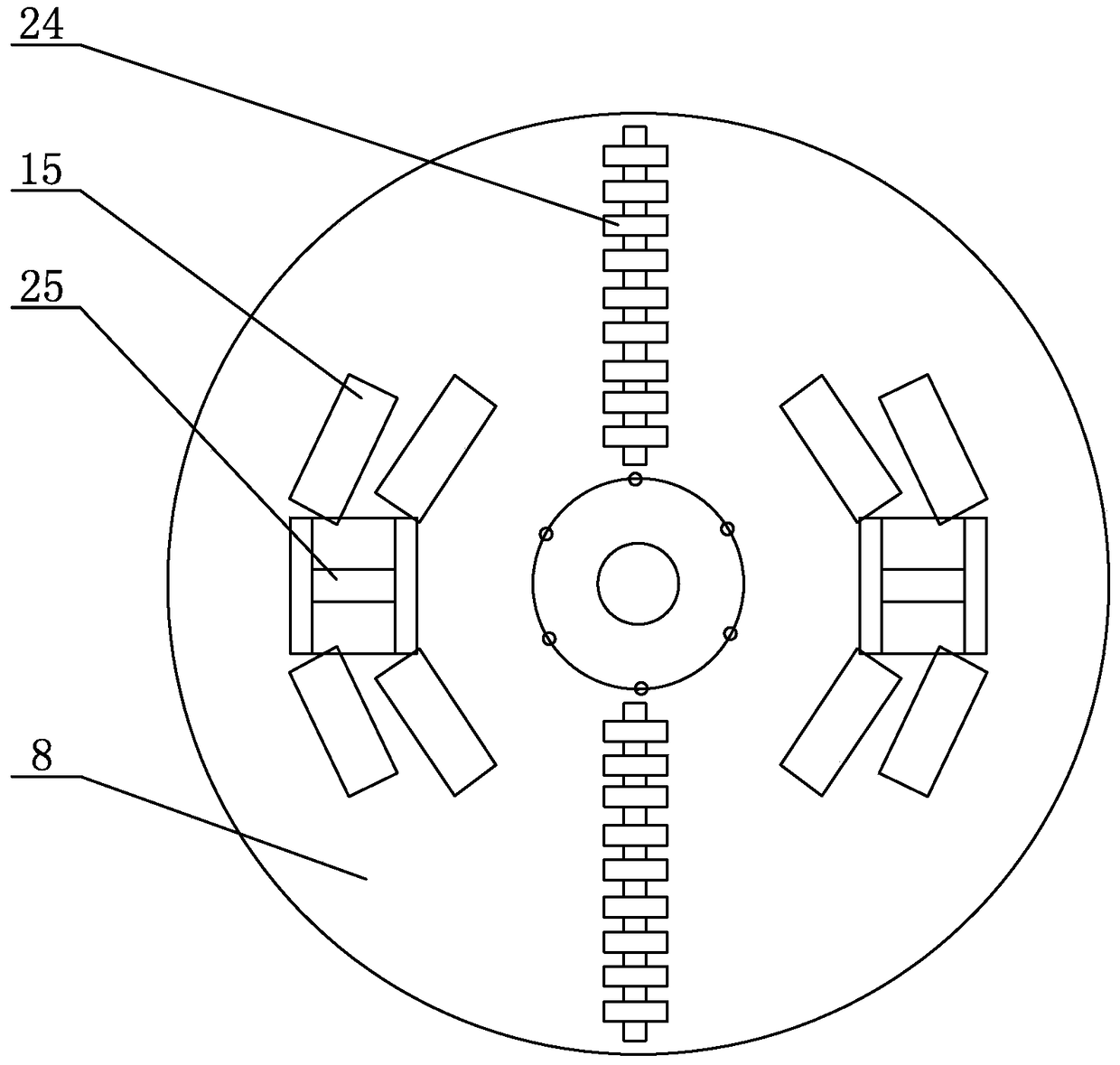

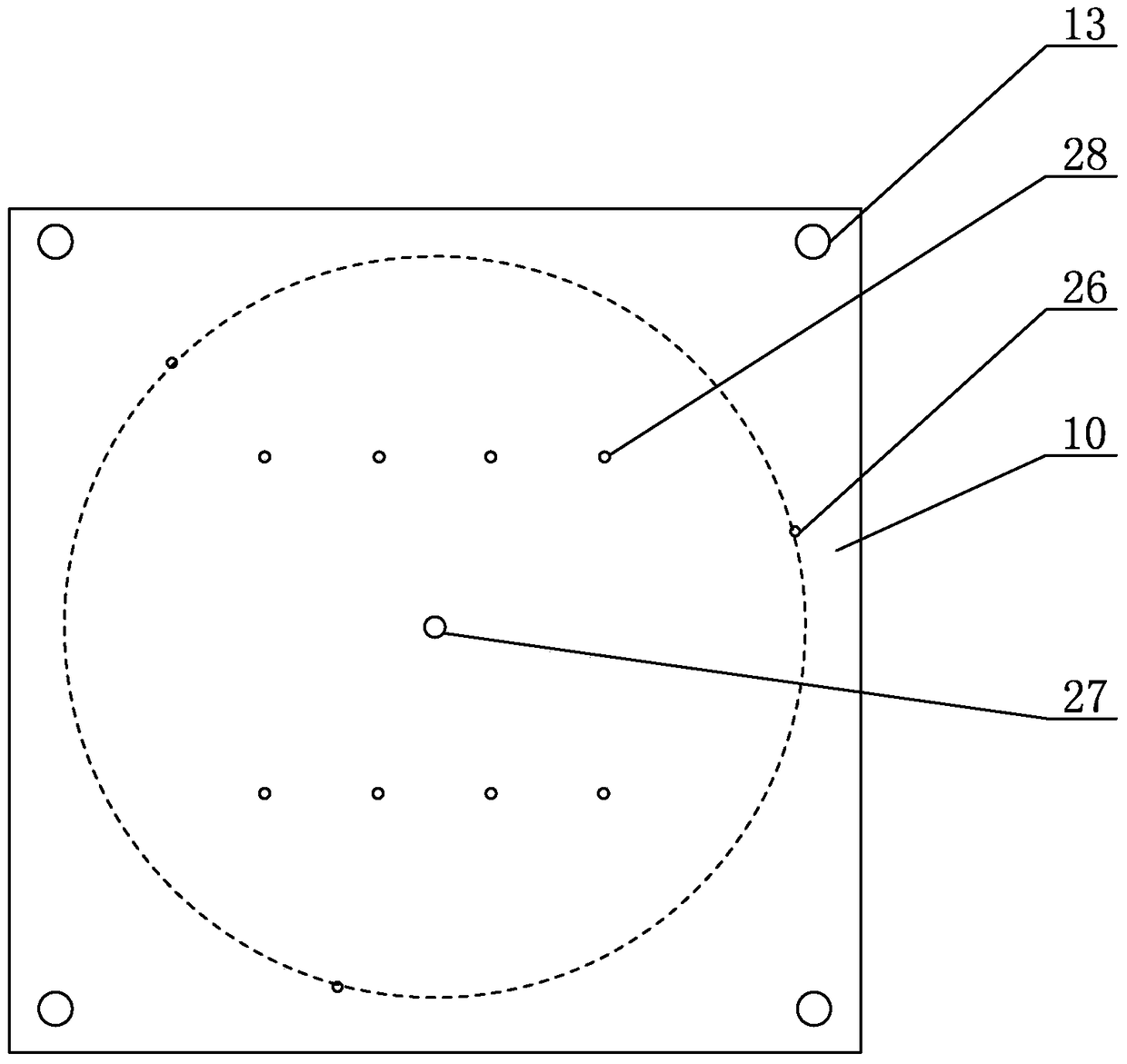

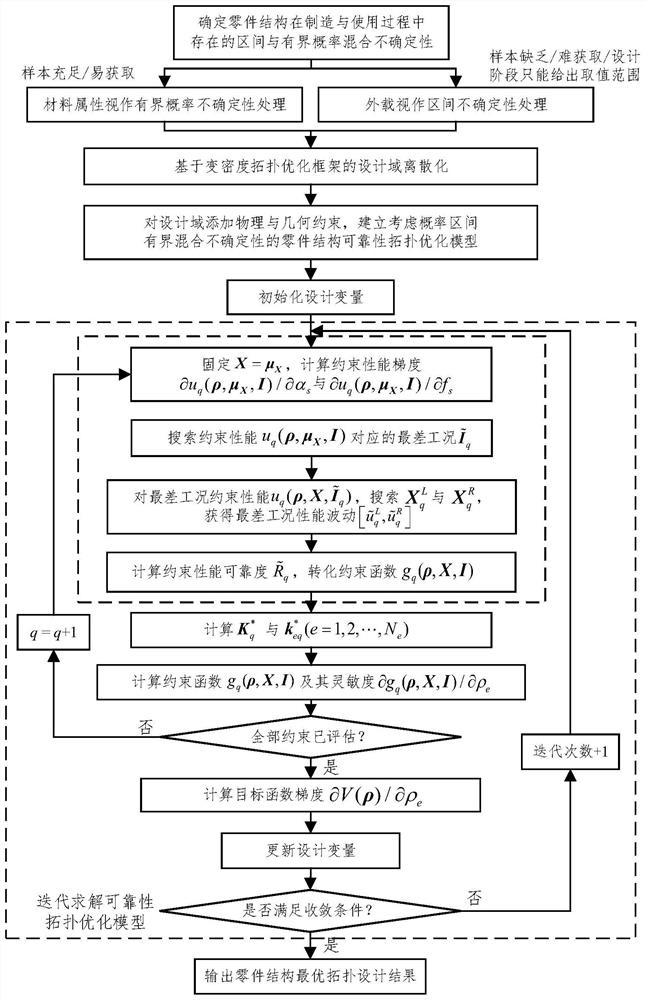

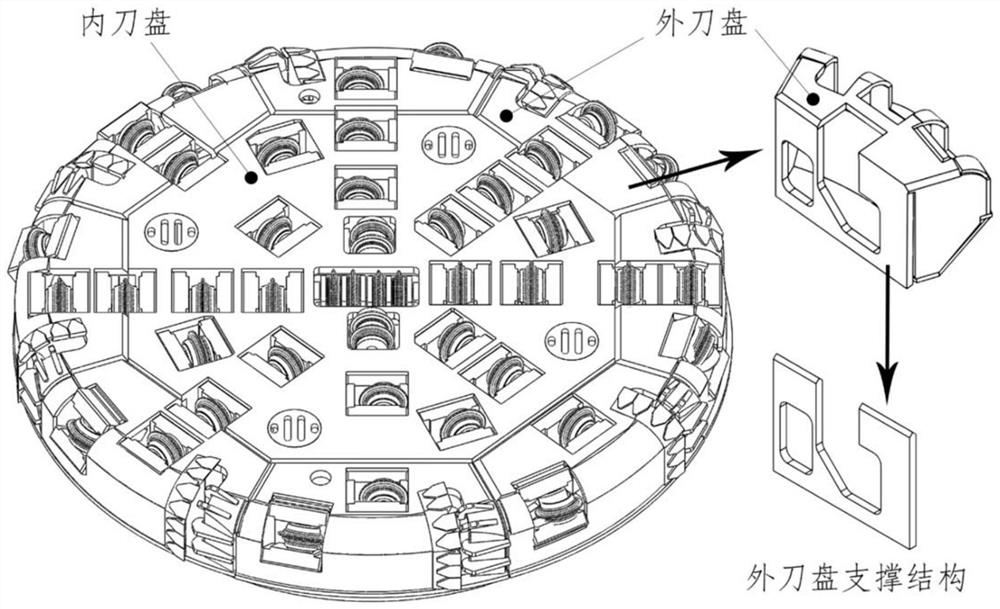

Part structure reliability topological optimization design method considering bounded hybrid uncertainty

ActiveCN113032918AOvercoming only probabilitiesOvercoming the Insufficiency of Interval UncertaintyGeometric CADDesign optimisation/simulationStructural reliabilityAlgorithm

The invention discloses a part structure reliability topological optimization design method considering bounded hybrid uncertainty. The method comprises the following steps: considering uncertainty in part structure manufacturing service, and respectively describing external loads with insufficient samples and material attributes with sufficient samples as interval variables and bounded probability variables; and discretizing a part structure design domain, setting physical and geometric constraints, and establishing a reliability topological optimization design model. Solution by utilizing a moving asymptote method comprises: decoupling probability interval uncertainty, and determining a worst working condition by utilizing a constraint performance gradient; defining worst working condition performance fluctuation and calculating constraint performance reliability; and finally calculating the gradient of the target and the constraint function on the design variable for iteration. The optimization design model established by the method truly reflects the distribution characteristics of the multi-source uncertainty of the part structure, is efficient in solving, and has good engineering application value.

Owner:ZHEJIANG UNIV

An ultrasonic positioning method for the core of a sic fiber reinforced ti-matrix composite ring

ActiveCN104820020BImprove processing qualityEnsure safe serviceAnalysing solids using sonic/ultrasonic/infrasonic wavesAlloySic fiber

The invention discloses an ultrasonic positioning method of a SiC fiber reinforced Ti-base composite material ring piece core, and belongs to the technical field of preparation and detection of a composite material. A SiC fiber reinforced Ti-base composite material ring piece has a sandwiched structure and consists of a composite material ring core and a peripheral Ti alloy outer sleeve. By utilizing a water leaching focusing ultrasonic detection method, firstly the accurate sound speed of ultrasonic waves in the composite material ring core and the Ti alloy outer sleeve is acquired by virtue of a measurement-aided calculation method, and then a distance from the surface of the ring piece to the core and the contour size of the ring piece core are measured by utilizing the sound speed, so that the ring piece core can be accurately positioned. By adopting the method, important significance on improving the machining quality of the SiC fiber reinforced Ti-base composite material ring piece and guaranteeing the safety application can be achieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A test system and method for testing the high temperature deformation resistance of airport asphalt pavement

ActiveCN105181478BAccurate evaluation of high temperature permanent deformation resistanceEnsure safe serviceMaterial strength using tensile/compressive forcesMaterial strength using steady torsional forcesHydraulic cylinderLow load

The invention relates to a testing system and a testing method, in particular to a testing system and a testing method applied to a testing of the high temperature deformation resistance of an asphalt airport pavement; the invention aims at solving the problem that an asphalt airport pavement material testing is conducted under the conditions of low load and single-wheel load and the condition that a load action form does not meet the practical situation due to the fact that an existing method of evaluating the high temperature permanent deformation resistance of the asphalt airport pavement depends on a method of evaluating the rutting resistance of a highway engineering bituminous mixture. The testing system disclosed by the invention comprises a motor, a motor supporting seat, a main shaft, a plurality of guide pillars, a top fixed plate, a bottom fixed plate, a rubber wheel supporting disk, a charging tray, a supporting plate, a hydraulic cylinder, a pressure sensor, rubber wheels, a plurality of supporting wheels, an upper bearing block, a lower bearing block, a rubber wheel disk connecting sleeve and a bottom plate; the top fixed plate, the bottom fixed plate, the supporting plate and the bottom plate are arranged in parallel from top to bottom in sequence; the guide pillars are evenly distributed. The testing system and the testing method disclosed by the invention are used for the field of road and bridge construction.

Owner:HARBIN INST OF TECH +2

A Topological Optimization Design Method for Reliability of Component Structures Considering Bounded Mixed Uncertainties

ActiveCN113032918BIn line with engineering practiceEnsure safe serviceGeometric CADDesign optimisation/simulationStructural reliabilityAlgorithm

Owner:ZHEJIANG UNIV

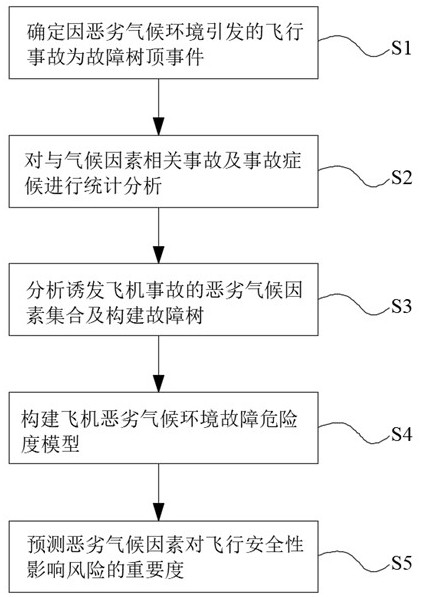

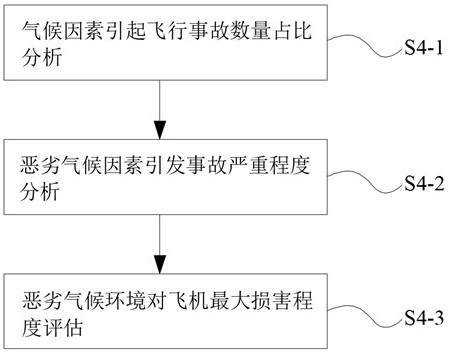

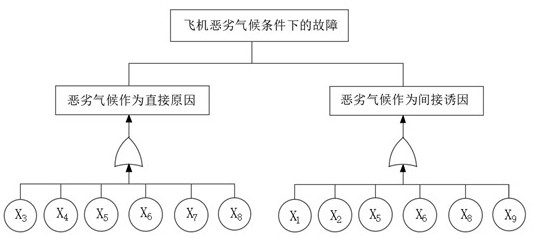

An FTA-based fault test and analysis method for aircraft in harsh climate environment

ActiveCN114493055BEnsure safe serviceThe mapping relationship is authentic and credibleForecastingStructural/machines measurementWeather factorStatistical analysis

The invention provides an FTA-based method for testing and analyzing aircraft severe weather environment faults, belonging to the technical field of aircraft testing. Including the following steps: S1, determine the flight accident caused by the bad weather environment as a fault tree top event; S2, carry out statistical analysis on the accident and the accident symptoms related to the weather factor; S3, analyze the set of bad weather factors that cause the aircraft accident and construct the fault tree; S4, construct a failure risk model of the aircraft in severe weather environment; S5, predict the importance of the risk of adverse weather factors affecting flight safety. The invention solves the problem that the prior art lacks the failure analysis method for the aircraft's harsh climate environment, which is not conducive to the design of the aircraft climate test in the climate environment laboratory of the whole aircraft, and has the advantages of simple operation and strong applicability.

Owner:CHINA AIRPLANT STRENGTH RES INST

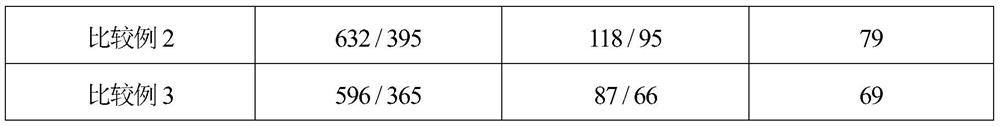

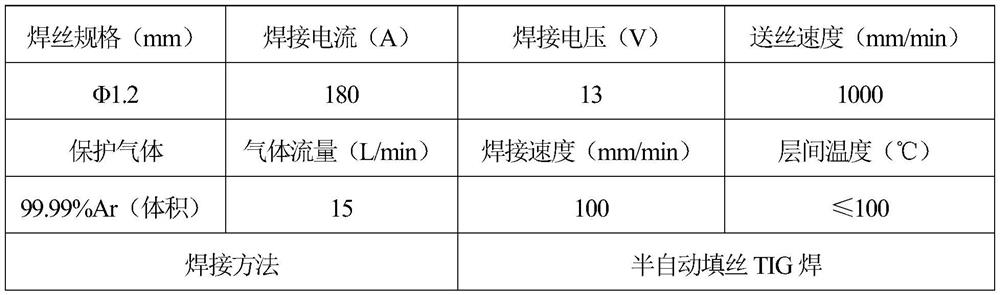

Austenitic stainless steel welding wire for high-level waste vitrified body container and its preparation method and application

ActiveCN107617830BImprove corrosion resistanceWeld firmlyWelding/cutting media/materialsSoldering mediaWire rodIngot

The invention discloses an austenitic stainless steel welding wire for a high-level waste glass solidified body container and a preparation method and application of the austenitic stainless steel welding wire, and belongs to the technical field of welding materials. The elementary chemical components of the austenitic stainless steel welding wire are composed of, by weight, 0.04-0.12% of C, 24.0-26.0% of Cr, 19.0-21.0% of Ni, less than or equal to 2.0% of Mn, less than or equal to 1.0% of Si, 0.3-1.0% of Nb, less than or equal to 0.1% of N and the balance Fe. The preparation process of the welding wire comprises the steps that a mother alloy steel ingot is prepared by adopting vacuum melting and forged to be a square billet after being subjected to heat preservation for 1-3 h at the temperature of 1100-1200 DEG C; the square billet is subjected to hot continuous rolling to be a steel wire rod after being subjected to heat preservation for 1-2 h at the temperature of 1100-1150 DEG C; and finally, the steel wire rod is manufactured into the welding wire after being subjected to continuous cold drawing. The welding wire is used for welding of the high-level waste glass solidified body container, the requirement for the product container material performance can be met, and the welding wire has good high-temperature strength and good impact toughness.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Turbine shaft-end seal device applied to Kalina power circulating system

ActiveCN108457707AWill not corrodeAvoid corrosionLeakage preventionMachines/enginesEngineeringAmmonia

The invention provides a turbine shaft-end seal device applied to a Kalina power circulating system. The device comprises a spiral seal system and a water seal system, wherein the spiral seal system comprises a spiral shaft sleeve, a stationary sleeve, a leak collecting cavity, a seal cavity and a mechanical seal; the spiral shaft sleeve is embedded onto the main shaft of a Kalina power circulating turbine, the stationary sleeve and the spiral shaft sleeve are arranged in a spaced manner at the same end of the main shaft in a sleeving manner to form the spiral seal, the seal end of the stationary shaft and the end part of the main shaft form a sealed cavity, the open end of the stationary sleeve and the main shaft form a cavity as the leak collecting cavity, and the mechanical seal arranged between the stationary sleeve and the main shaft is located in the leak collecting cavity; when the main shaft rotates, the spiral shaft sleeve rotates to pressurize the seal cavity; the water sealsystem comprises a pressurizing pump, an adjusting valve and a water tank; the input end of the water tank communicates to the leak collecting cavity while the output end of the water tank communicates to the tail end of the gap between he spiral shaft sleeve and the stationary sleeve successively through a pressurizing pump and the adjusting valve. Through three seals: the mechanical seal, the water seal and the spiral seal, the problem of corrosion caused by contact of ammonia-enriched steam and the mechanical structure is avoided.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com