Patents

Literature

30results about How to "Full of perfusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

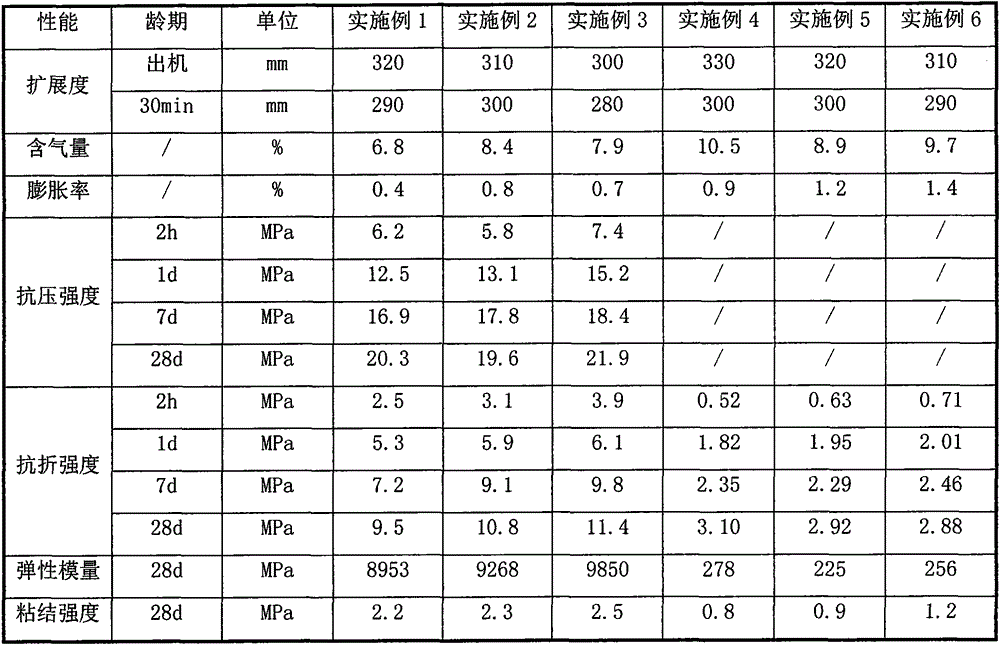

Polymer cement mortar for slab ballastless track of high-speed railway

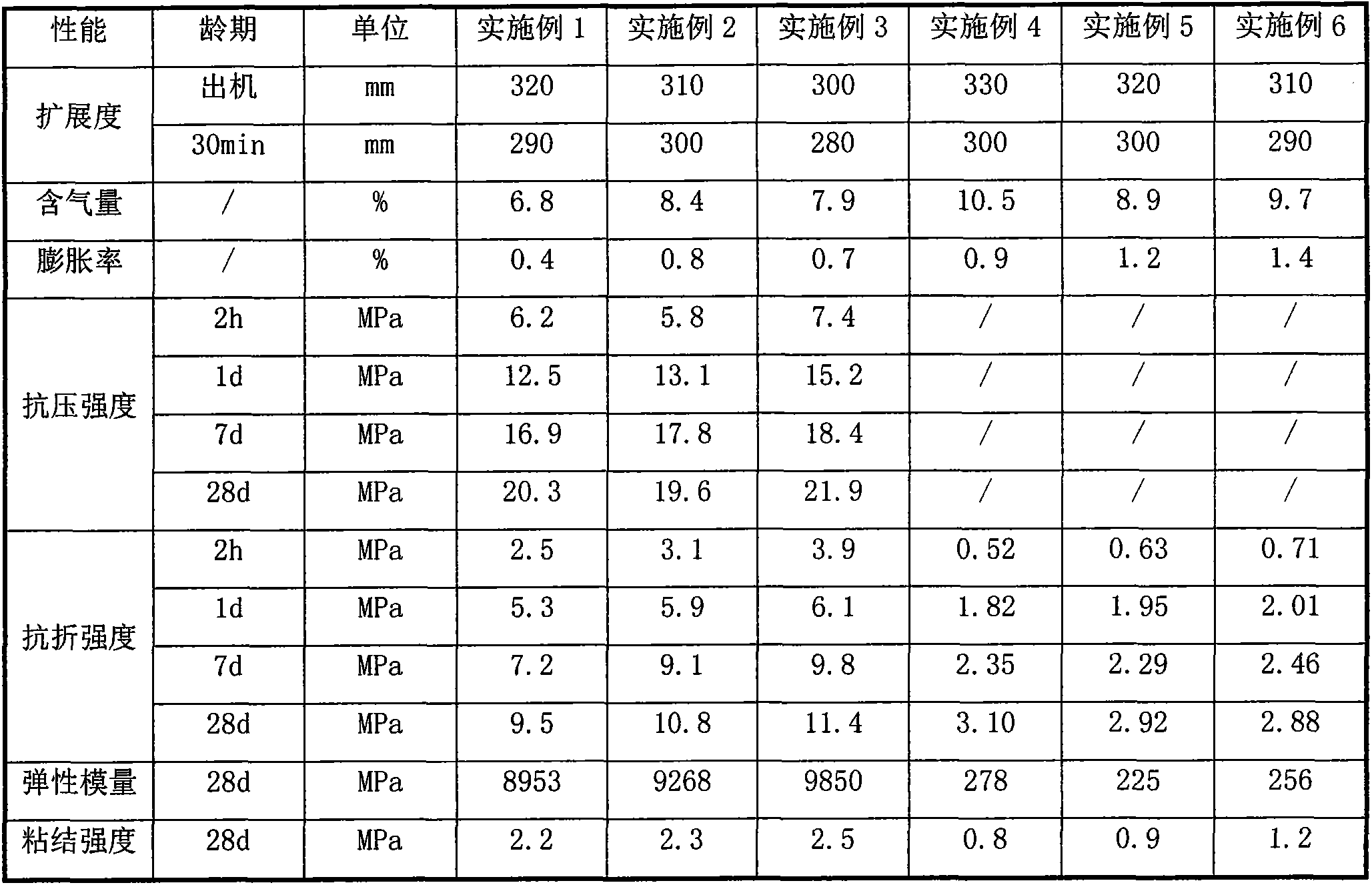

The invention discloses polymer cement mortar for a slab ballastless track of a high-speed railway. The polymer cement mortar a comprises a dry raw material and a liquid raw material, wherein the dry raw material comprises a binding material component, an elastic adjusting component, an expanding component, an internal curing component, an aggregate component and a coagulation adjusting component; the liquid raw material comprises a polymer emulsion, a water reducing agent, a defoaming agent, an air entraining agent and water; and the weight ratio of the dry raw material to the liquid raw material is 100:(15-25), and the dry raw material and the liquid raw material are uniformly mixed in a proportion to prepare the polymer cement mortar. The polymer cement mortar has the advantages of controllable coagulation time, high adhering strength, adjustable elastic modulus, good elasticity and toughness, high durability and the like, and is capable of replacing cement emulsified asphalt mortar to be applied to a packing material of the slab ballastless track or can be used as a quick repairing material of a filling layer of cement emulsified asphalt mortar.

Owner:BEIJING TIEKE SPECIAL ENG TECH CO LTD +1

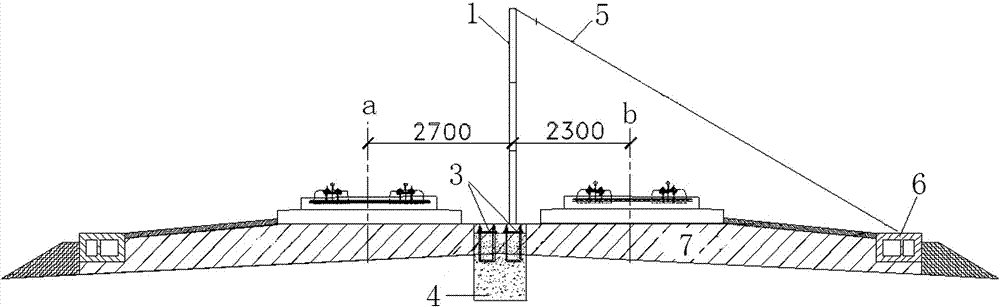

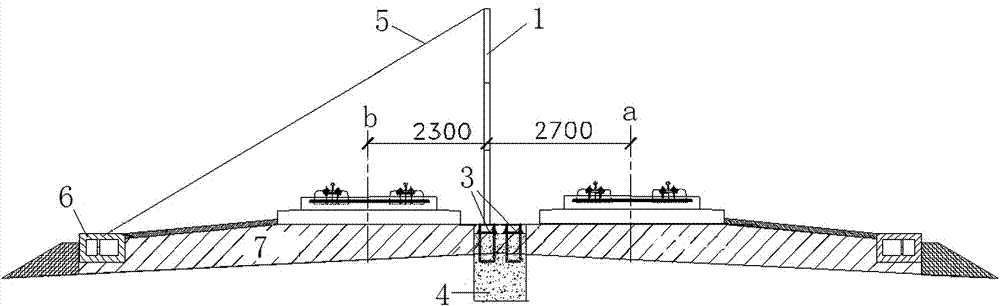

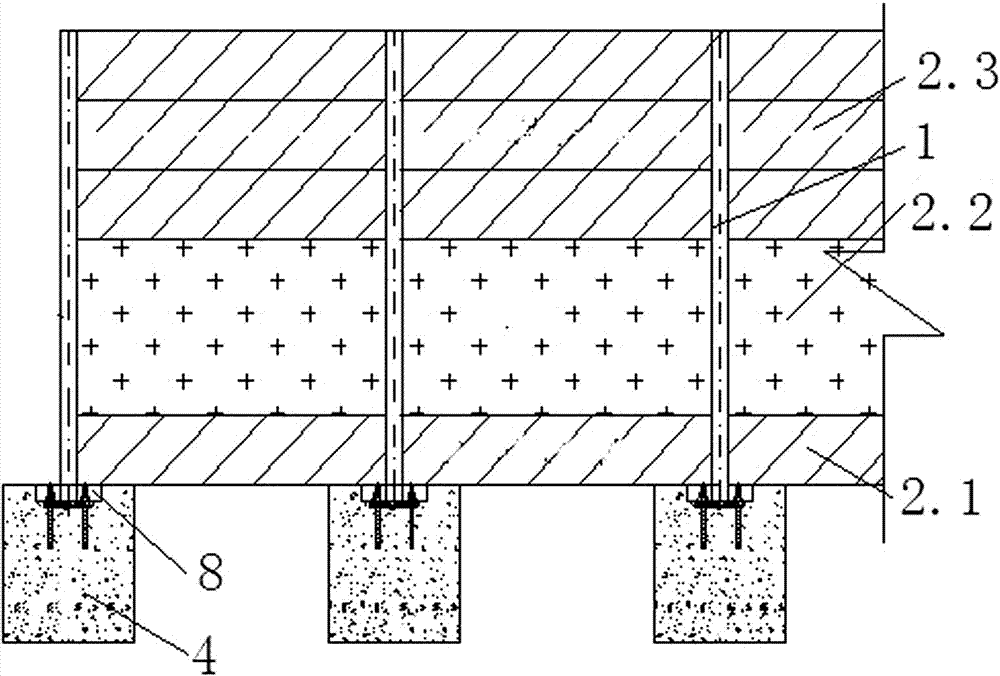

High-speed railway ballastless track line rapid repairing method

ActiveCN106868959AEfficient repairEffective MaintenanceBallastwayRailway track constructionSurface layerLong term durability

The invention belongs to the technical field of high-speed railway ballastless track repairing and provides a high-speed railway ballastless track line rapid repairing method in order to solve the problem that at present, a complete set of effective, rapid and systematic repairing method is not available for existing high-speed railway ballastless track lines. The high-speed railway ballastless track line rapid repairing method comprises the steps of line-to-line physical isolator installation, track sawing and moving, integral concrete track bed cutting and transporting, subgrade bed surface layer graded broken stone measurement leveling, supporting layer construction, track bed slab construction, steel track welding locking, track fine adjustment, road shoulder waterproof and drainage engineering and related engineering installation; line-to-line physical isolator demolition, line-to-line sealing layer and related engineering recovery, steel track polishing derusting, line-to-line waterproof construction, and drainage side ditch and side ditch platform recovery construction. Implementation is easy, and the high-speed driving requirement is met after repairing; the repairing and reinforcement effect is good, and the situation that a problem happens again to a ballastless track is effectively prevented; and the high-speed railway ballastless track is efficiently, rapidly, completely, systematically and comprehensively repaired and maintained, so that the safety of railway operation and the long-term durability of the structure of the ballastless track are ensured.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

Method for repairing and reinforcing open joint of filling layer of slab ballastless track

InactiveCN104404844ASolve the seam diseaseSimple processRailway track constructionEngineeringLayered structure

The invention discloses a method for repairing and reinforcing an open joint of a filling layer of a slab ballastless track and belongs to the technical field of high speed railway engineering maintenance. The method comprises the following steps of drilling and anchoring a slab of the track with the open joint; grouting and repairing an open joint area of the filling layer. The method solves the problem that an effective method for repairing the open joint of the filling layer is lacked in the prior art; the method is simple and quick in procedures and easy to implement, can effectively eliminate the open joint of the filling layer of the slab ballastless track structure, ensures that the requirement on high speed running is met after repair, can be used for repairing and reinforcing the open joint of the filling layer of the slab ballastless track of a high speed railway, and can also be used for repairing and reinforcing other projects with layered structures.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

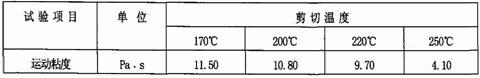

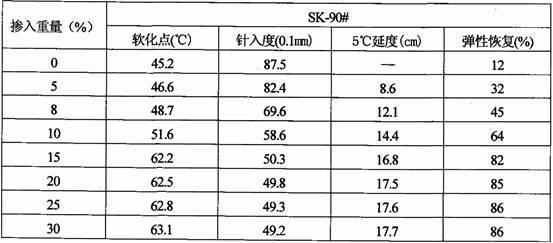

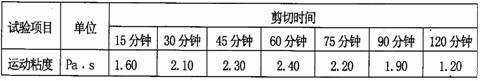

Asphalt pavement crevice embedding sealing material and preparation method thereof

InactiveCN101235207AReduce pollutionAvoid it happening againPaving detailsBuilding insulationsMechanical engineeringAccelerant

Asphalt pavement crack inbuilt-enveloping material and a preparation process are disclosed, wherein the material is prepared by 5%-60% asphaltum, 10%-25% rubber powder, 15%-25% bulking agent, 2%-14% accelerating agent and 1%-3% compatibilizer. The preparation process comprises adding asphaltum in an autoclave, heating up to the temperature of 140-160 DEG C, then adding rubber powder, compatibilizer and accelerating agent, stirring for 20 minutes with 300-1500 rotation / min, elevating the temperature to 170-220 DEG C, shearing 30-45 minutes with a high speed shearer, then adding bulking agent, developing 45-90 minutes in a storage tank, then finally preparing the product of the invention. The product of the invention is used on the crack inbuilt-enveloping, and has large adhesive force with cracks, can effectively prevent from generating new cracks, has favorable flow, is easy to be injected in cracks, has excellent affinity with cracks, and can be fully affused, and has large adhesive surface. The asphalt pavement crack inbuilt-enveloping material is suitable to be used to remand asphalt pavement cracks.

Owner:陕西长大博源公路养护科技有限公司

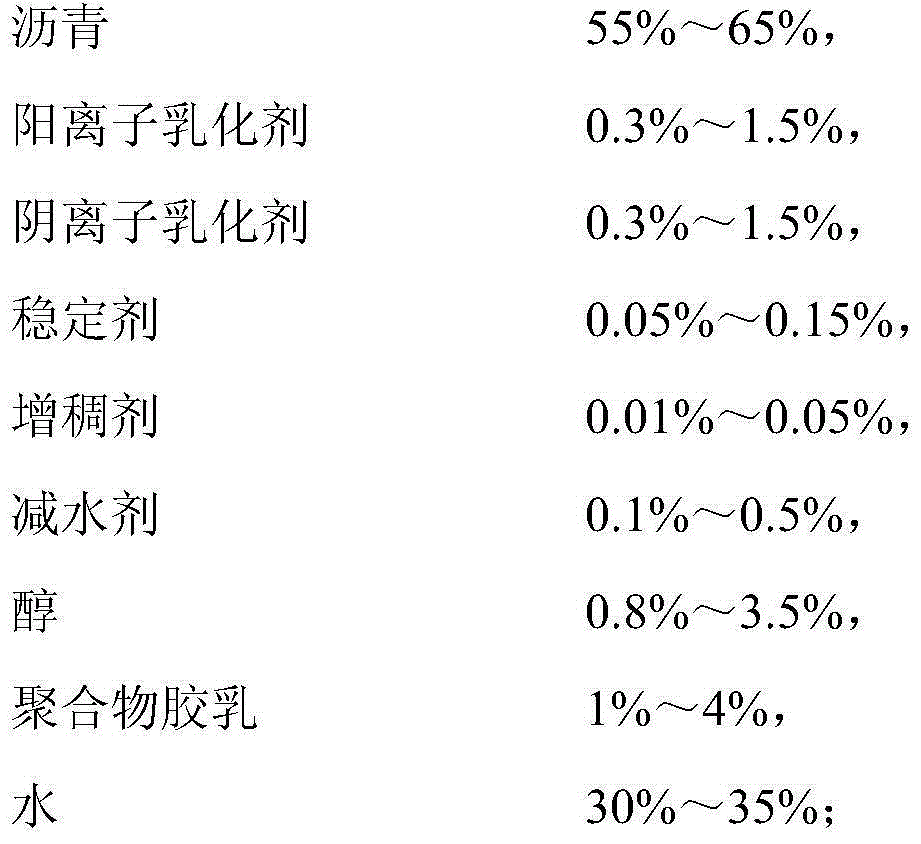

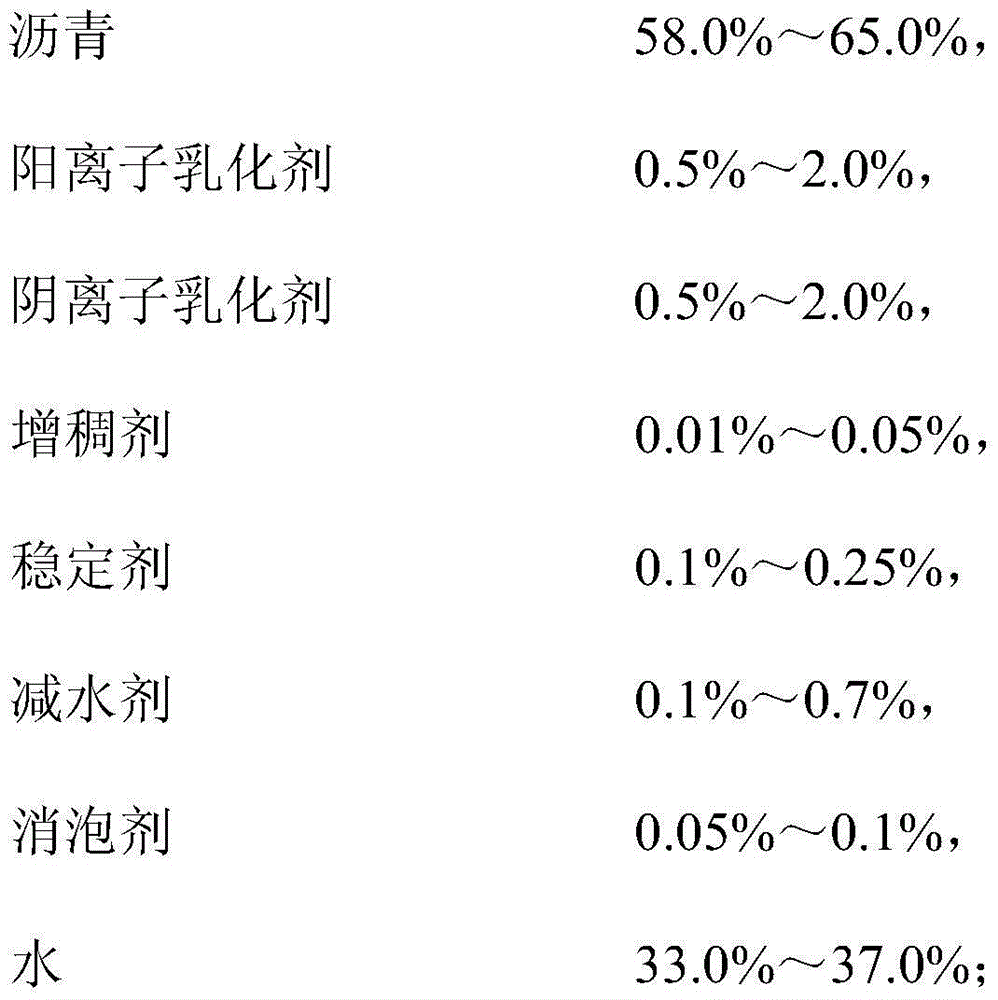

Emulsified asphalt and preparation method thereof

The invention discloses an emulsified asphalt and a preparation method thereof. A formula of the emulsified asphalt comprises asphalt, a cationic emulsifier, an anionic emulsifier, a thickener, a stabilizer, a water reducing agent and water. According to the invention, the water reducing agent is added to asphalt emulsion as a component for not only playing the role of the reducing agent itself, reducing operation steps during construction, but also for cooperating with the cationic surfactant and the anionic surfactant, thus obviously improving sieve residual amount, storage stability and especially indexes of cement miscibility of the emulsified asphalt. The emulsified asphalt provided by the invention is used for cement asphalt mortar pouring of a plate-type ballastless track during construction of a high-speed railway.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anti-freezing emulsified asphalt and preparation method thereof

ActiveCN103059581AImproved sieve residueGood storage stabilityBuilding insulationsPolymer scienceAlcohol

The invention discloses an anti-freezing emulsified asphalt and a preparation method thereof. A formula of the emulsified asphalt comprises asphalt, an anionic emulsifier, a cationic emulsifier, a thickener, a stabilizer, a water reducing agent, alcohol and water. The method provided by the invention comprises steps of: dissolving the water reducing agent and the thickener in alcohol at room temperature to prepare a paste, and adding a defoaming agent into the paste; and then participating the paste in the emulsion as a whole. The paste is combined with the cationic emulsifier and the anionic emulsifier emulsifier, so as to reduce usage amount and cost of emulsifier, and obviously improve sieve residue, storage stability, cement miscibility and frost resistance of the emulsified asphalt.

Owner:CHINA PETROLEUM & CHEM CORP +1

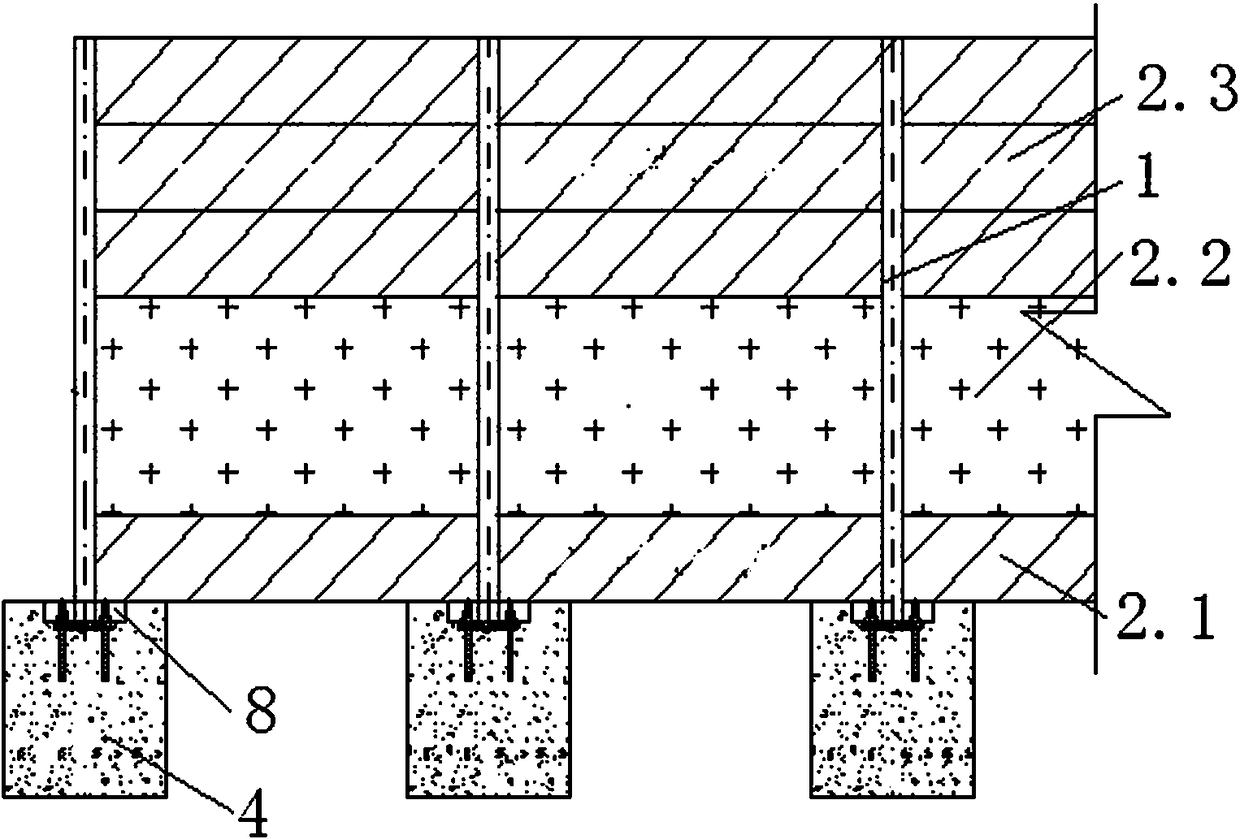

Method for rapidly repairing cement emulsified asphalt mortar interface connection damage of unit slab ballastless track

ActiveCN104480815AGuaranteed smoothnessEasy constructionRailway track constructionPressure groutingComing out

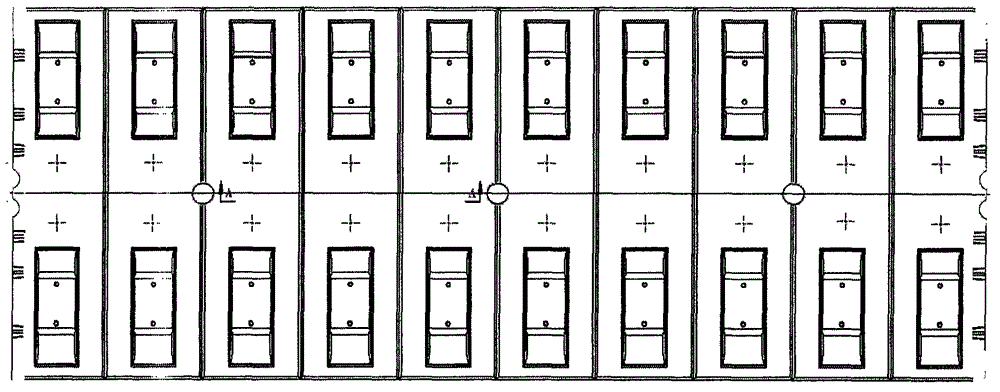

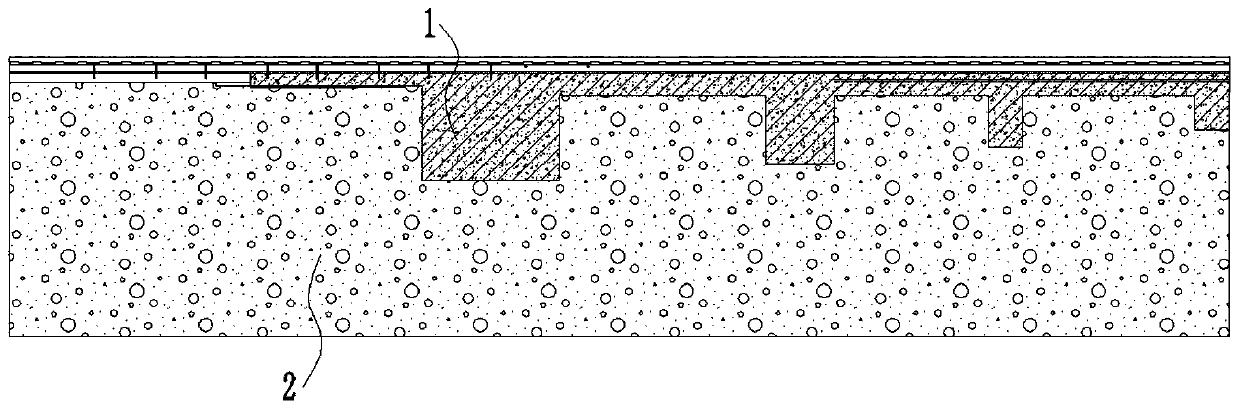

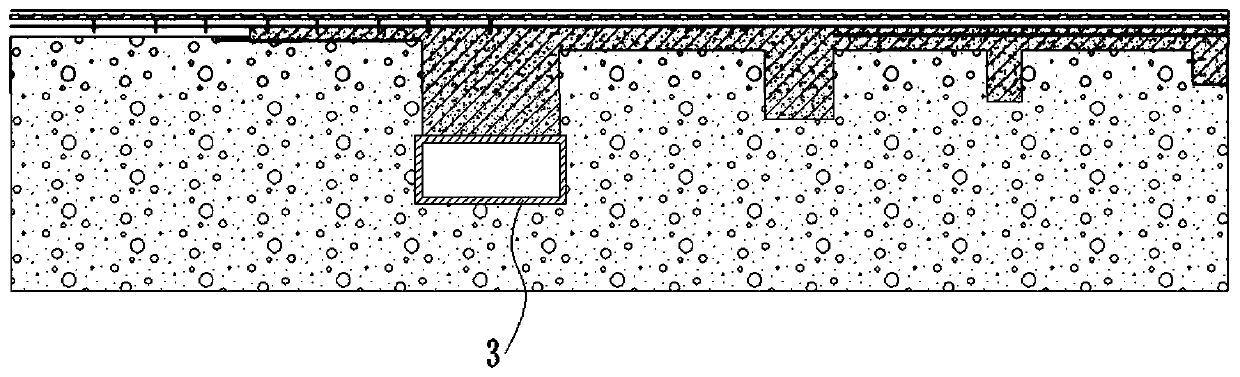

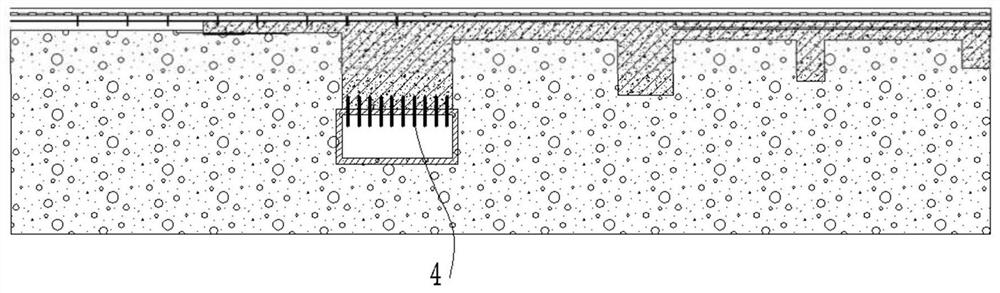

The invention relates to a method for rapidly repairing cement emulsified asphalt mortar interface connection damage of a unit slab ballastless track; the method mainly comprises the steps of cleaning, sealing, setting of grouting openings, interface connection damage grouting and edging treatment; the specific steps are as follows: firstly, cleaning dust and impurities around a mortar interface connection damage; secondly sealing the interface connection damage area, setting the grouting openings and placing a dial indicator at four corners of a track slab in a to-be-repaired area; thirdly, connecting a dual-component self-mixing grouting machine with a pressure grouting hose, and injecting a dual-component grouting material to the grouting openings in sequence; after the mortar comes out of a grouting opening having the spacing of more than the width of the track slab with the next grouting openings, turning to the next grouting opening to grout continuously till the whole cement emulsified asphalt mortar seam area is fully grouted; and finally, cutting the grouting hose, polishing sealed materials to finish the repairing. The method has the characteristics of simple and rapid process, high repairing efficiency and capability of realizing rapid repairing within skylight time and is applicable to repairing the cement emulsified asphalt mortar seams of the unit slab ballastless track.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

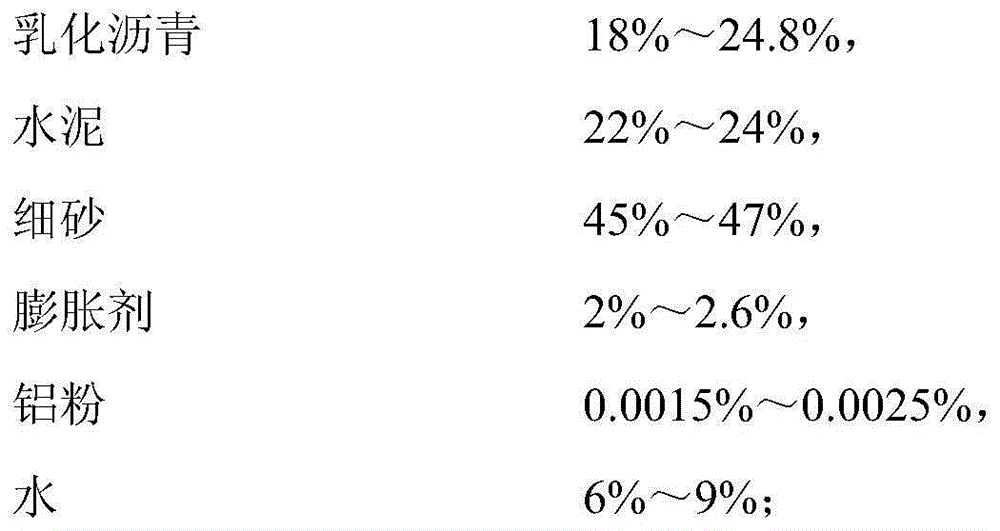

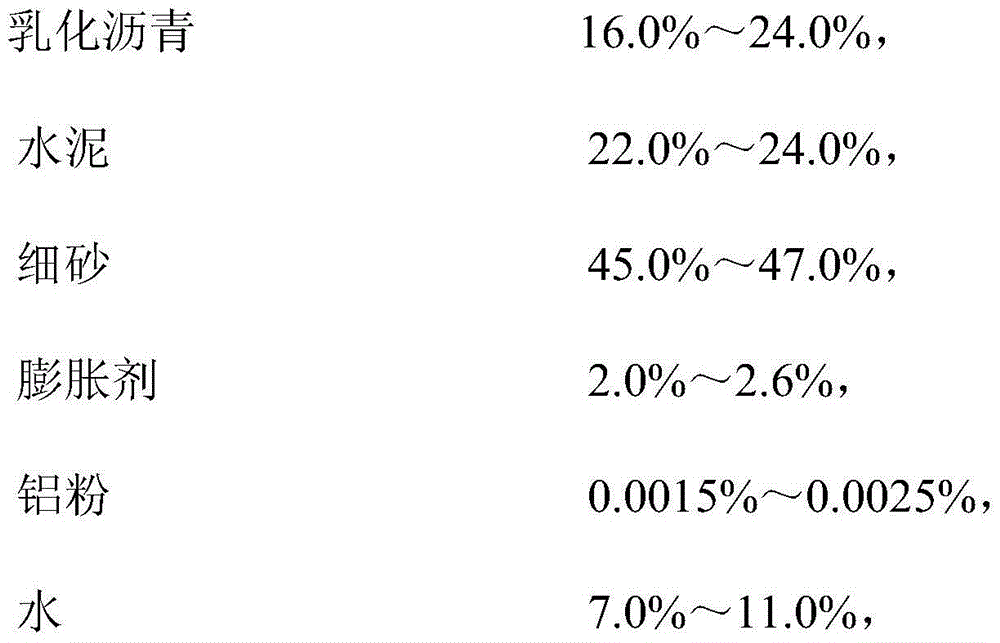

Anti-freezing cement asphalt mortar and preparation method thereof

The invention discloses an anti-freezing cement asphalt mortar and a preparation method thereof. The cement asphalt mortar comprises emulsified asphalt, cement, fine sand, an expansive agent, an aluminite powder and water. A formula of the emulsified asphalt comprises asphalt, an anionic emulsifier, a cationic emulsifier, a thickener, a stabilizer, a water reducing agent, a defoaming agent, alcohol and water. The cement asphalt mortar provided by the invention employs special emulsified asphalt; and when the cement asphalt mortar is mixed with dry material such as cement and sand, the water reducing agent and the defoaming agent are easily dispersed to fully contact with the dry material, thus realizing obvious water reducing effect, effectively avoiding bleeding phenomenon after pouring of CA mortar, and improving workability of the emulsified asphalt with cement and fine sand; and synergistic effect of alcohol improves anti-freezing performance of the CA mortar, effectively eliminates large bubbles, and realizes dense and uniform texture after forming of the CA mortar. The cement asphalt mortar provided by the invention is particularly suitable for perfusion under track plate as a buffer layer in construction of high-speed railway.

Owner:CHINA PETROLEUM & CHEM CORP +1

A rapid repair method of cement emulsified asphalt mortar for longitudinal slab ballastless track

ActiveCN104452499BImprove performanceNo on-site metering requiredBallastwayRailway track constructionCement mortarMaterials science

The invention relates to a method for rapidly repairing an open joint of cement-emulsified asphalt mortar of a longitudinally-connected-plate type ballastless track. The method mainly includes the working procedures of open joint cleaning, grouting opening forming, open joint closing, open joint grouting, edge cleaning and the like, and particularly includes the steps that dust and impurities on the periphery of the open joint of the cement-emulsified asphalt mortar are removed, a grouting opening is formed in the open joint, then an open joint area is closed through rapidly-solidified joint closing materials, after the joint closing materials are solidified, double-component polyurethane grouting materials are injected into the open joint by a double-component self-mixing grouting machine through the grouting opening, after open joint grouting is completed, the grouting opening and the redundant joint closing materials are removed, and repairing work is completed. The method has the advantages of being high in construction efficiency, good in repairing effect, capable of achieving rapid repairing within the skylight time and the like, is suitable for repairing the open joint of the cement-emulsified asphalt mortar of the longitudinally-connected-plate type ballastless track and is also suitable for rapidly repairing an open joint of a concrete structure of a layered structure.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

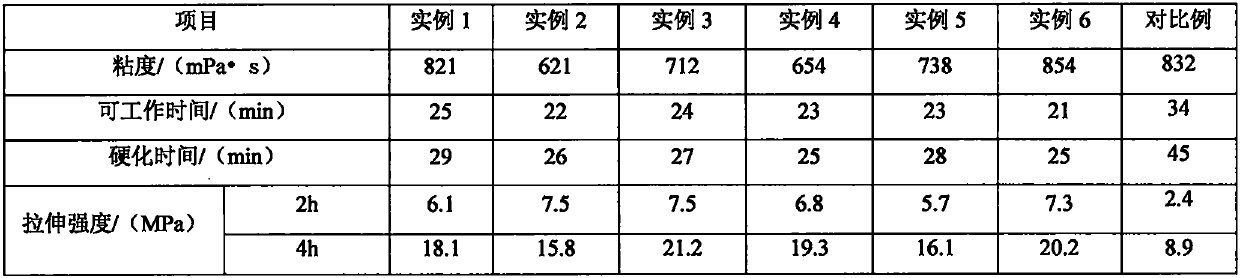

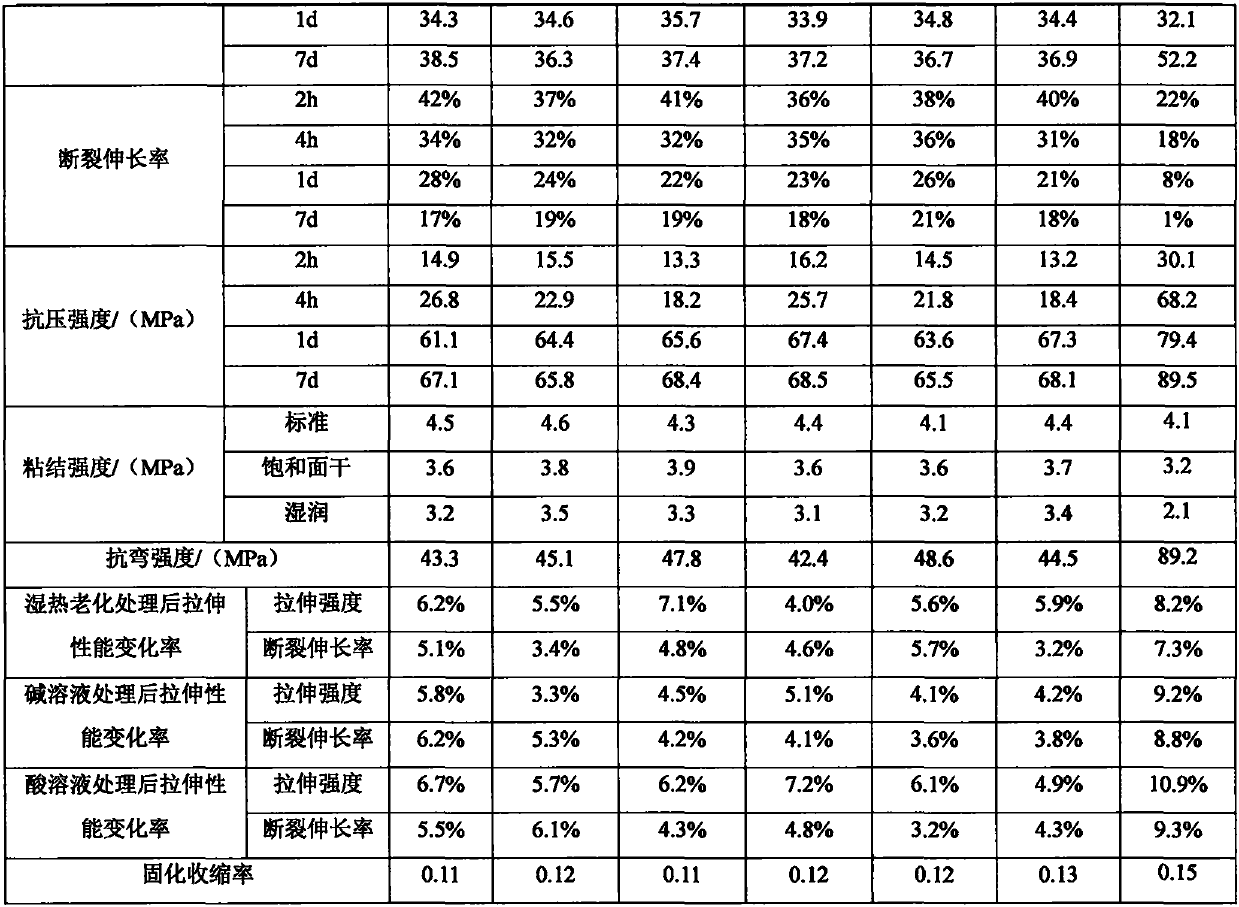

High-toughness epoxy resin grouting material for rapid repair of concrete structure joint

InactiveCN110903795AImprove performanceThe ratio is scientific and reasonableEpoxy resin adhesivesConjugated diene hydrocarbon adhesivesPolymer scienceFirming agent

The invention relates to a high-toughness epoxy resin grouting material for rapid repair of a concrete structure joint. The high-toughness epoxy resin grouting material is composed of the following raw materials: a component A and a component B, wherein the component A comprises: glycidyl ether epoxy resin, glycidyl ether epoxy resin, softened modified epoxy resin, epoxy-terminated liquid nitrilebutadiene rubber and a reactive diluent; and the component B comprises: a modified amine curing agent, polymercaptan, a tertiary amine accelerator, amino-terminated liquid nitrile butadiene rubber, anorganic silicon defoamer and an anti-aging agent, and the mass ratio of the component A to the component B is 1:0.2-1. The epoxy resin grouting material has low viscosity, is convenient for groutingconstruction, has good applicability to a humid basal plane, and has fast hardening speed, high early mechanical strength and bonding strength, excellent flexibility, and excellent damp-heat aging resistance and fatigue resistance, and can achieve rapid repair and reinforcement on a concrete structure joint without affecting normal traffic.

Owner:BEIJING MUNICIPAL ENG RES INST +1

A kind of polymer cement mortar used for filling layer of high-speed railway slab ballastless track

ActiveCN104030644BAchieve expansibilityAchieve low shrinkage and micro-expansion propertiesPolymer scienceRepair material

Owner:BEIJING TIEKE SPECIAL ENG TECH CO LTD +1

Method for preparing emulsified asphalt slurry

ActiveCN101642933AEasy to prepareQuality improvementSolid waste managementMixing operation control apparatusGas phaseSlurry

The invention discloses a method for preparing emulsified asphalt slurry. The emulsified asphalt slurry is formed by mixing and stirring emulsified asphalt, artificial sand, water, 40-50% acrylic emulsion, sweller, air entraining agent, defoaming agent and aluminum powder; the emulsified asphalt is formed by mixing emulsified asphalt 1# intermediate product and emulsified asphalt 2# intermediate product, adding stabilizer gas silica and evenly mixing; the emulsified asphalt 1# intermediate product is formed by mixing and grinding 1# emusifier prepared by adding water to asphalt, lignose, alkylamine, gas phase silica and polyoxyethylene derivative; and the emulsified asphalt 2# intermediate product is formed by mixing and grinding 2# emusifier prepared by adding water to asphalt, volcanic type amargosite. The emulsified asphalt slurry of the invention is high in strength, plump in pouring, simple in preparation method, low in raw material cost and perfect in construction performance.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

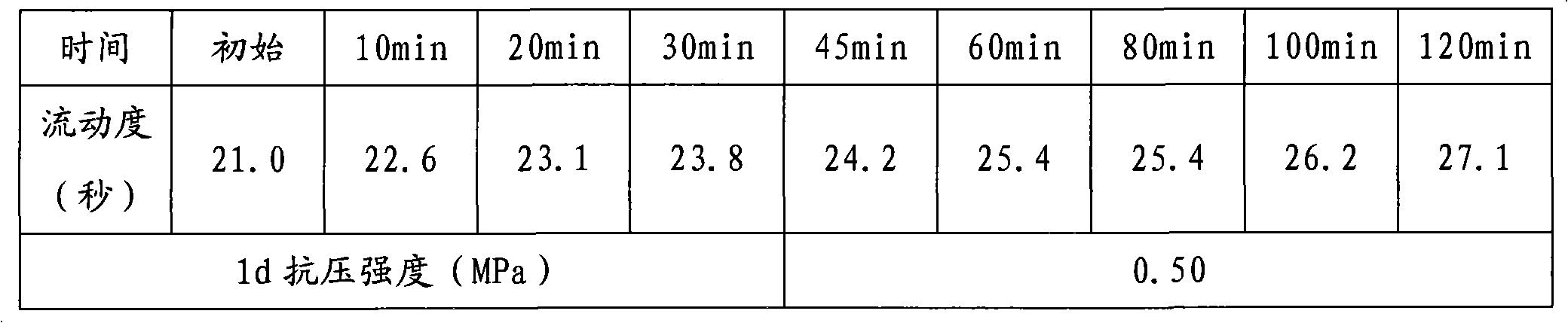

A kind of cement asphalt mortar and preparation method thereof

ActiveCN103803893BGood temperature sensitivityWide operating temperature rangeAlcoholPolymer science

The invention discloses cement asphalt mortar and a preparation method thereof. The cement asphalt mortar comprises emulsified asphalt, cement, fine sand, an expanding agent, aluminium powder, and water. The formula of the emulsified asphalt comprises asphalt, an anionic emulsifier, a cationic emulsifier, a stabilizing agent, a thickening agent, a water reducer, an antifoaming agent, alcohol, polymer latex and water. The cement asphalt mortar of the invention adopts specially prepared emulsified asphalt; when the emulsified asphalt is mixed with dry materials of cement, dry sand, and the like, the water reducer, the antifoaming agent, and the polymer latex are easy to disperse uniformly, and the contact with the dry materials is full; the water reduction effect is significant; the bleeding phenomenon of the CA mortar after pouring is effectively prevented; the workability of the emulsified asphalt with cement and fine sand is improved; with the synergistic effect of the alcohol, the freezing resistance of the CA mortar is improved; big bubbles are eliminated effectively; the CA mortar is compact and uniform in texture after molding, and has the characteristic of good weatherability. The cement asphalt mortar of the invention is especially suitable for being poured below a track plate during high speed railway building and used as a damping buffer layer.

Owner:CHINA PETROLEUM & CHEM CORP +1

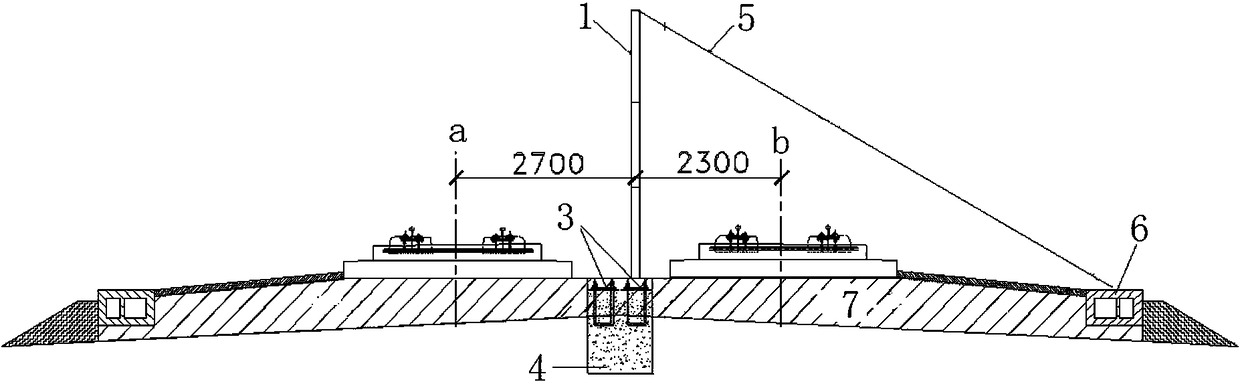

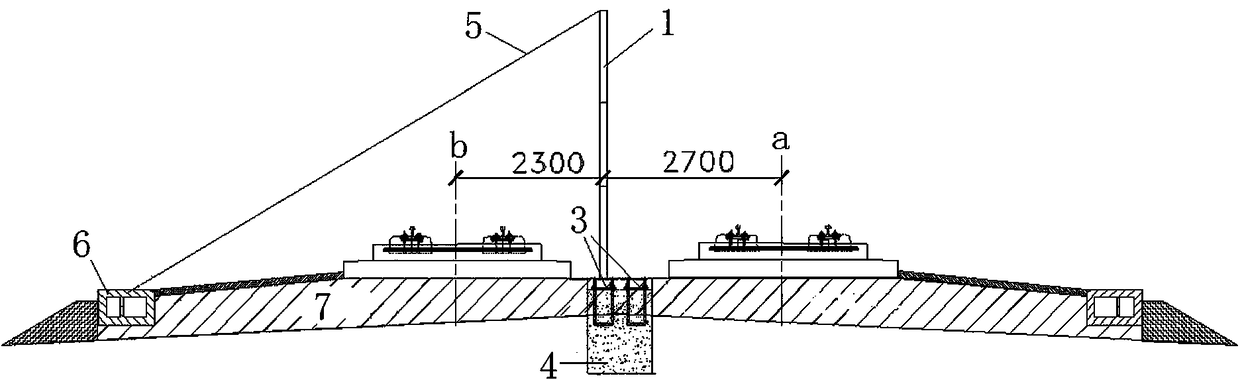

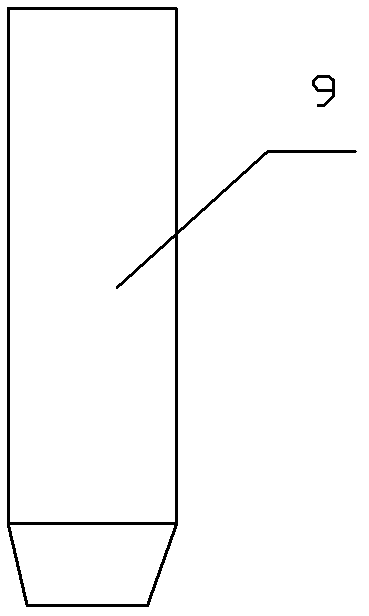

End thorn anchor force enhancing structure and construction method

ActiveCN111535079AIncrease anchoring forceReduced longitudinal displacementBallastwayAdhesive cementTrackway

The invention discloses an end thorn anchor force enhancing structure of a ballastless track and a construction method. The method comprises the following steps of measuring and monitoring a track elevation and a line center line; performing shield excavation at a bottom of a main end thorn of a n-shaped end thorn; forming grouting holes in the two sides and the bottom of a pipe wall of a shield structure, injecting grout into a roadbed AB-group filler through a floral pipe or a sleeve valve pipe, and forming the shield structure reinforced in a peripheral dendritic mode; vertically punching the top of the pipe wall of the shield structure upwards into the main end thorn, injecting adhesives into the holes, planting reinforcing bars in the holes, and connecting the shield structure with the main end thorn; pouring lightweight aggregate concrete into a cavity of the shield structure so that the reinforced shield structure and the existing end thorn are firmly combined into a whole, andforming a reinforced end thorn structure; and removing a template, repairing an off-line cable trough, and recovering a slope. By strengthening a height and an anchoring range of the main end thorn ofthe n-shaped end thorn, an anchoring force of the end thorn is remarkably increased; and purposes of reducing longitudinal displacement of the end thorn along a line and stabilizing the track structure of a road-bridge transition section are achieved.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

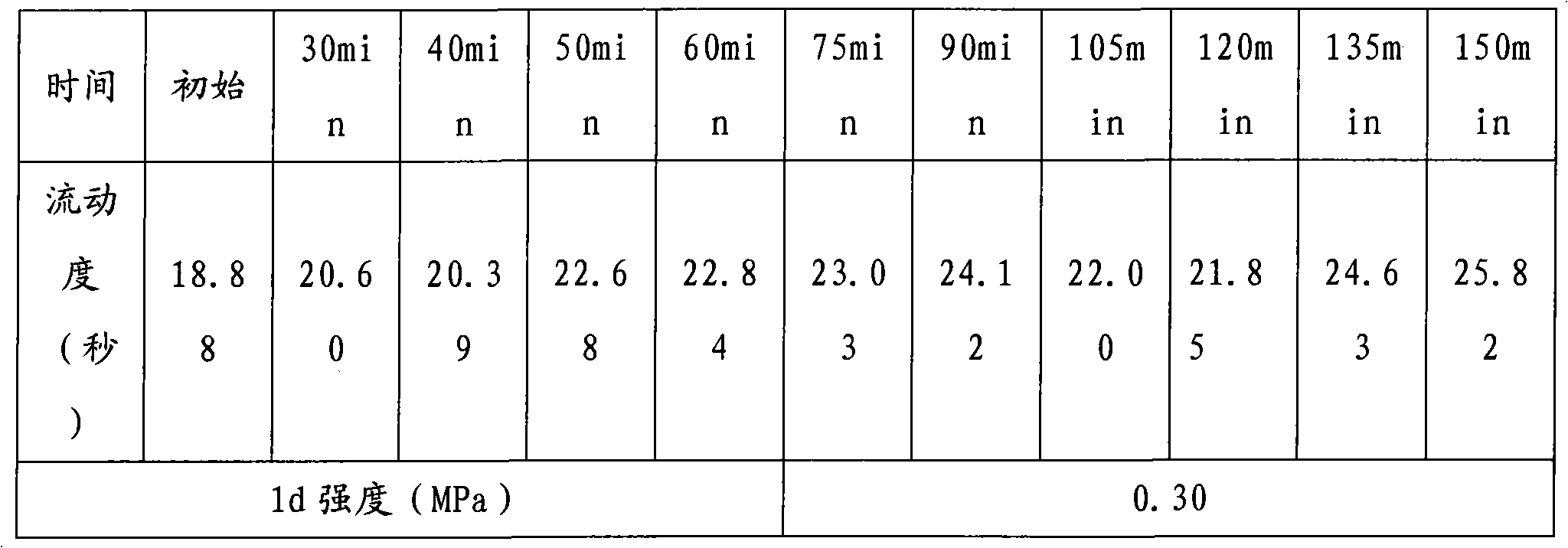

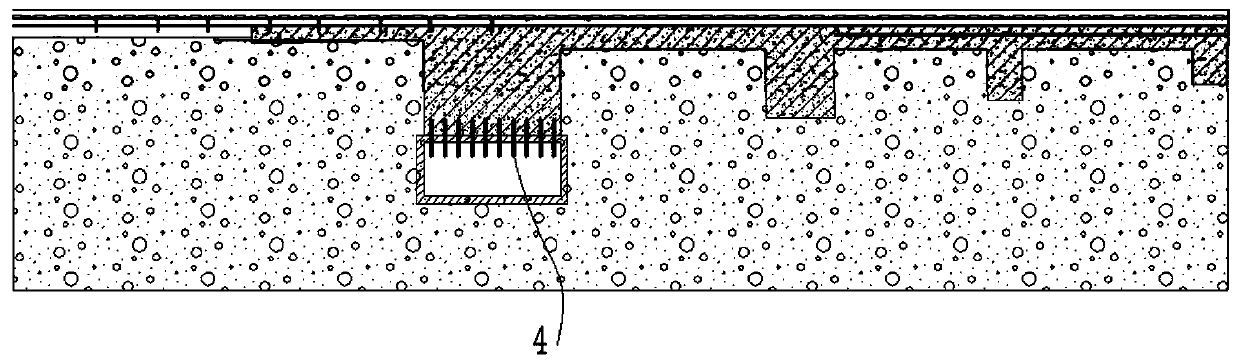

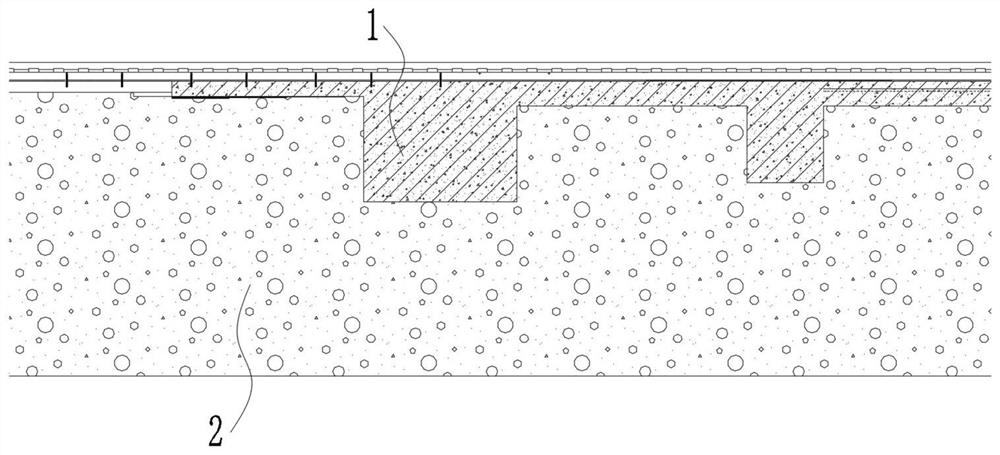

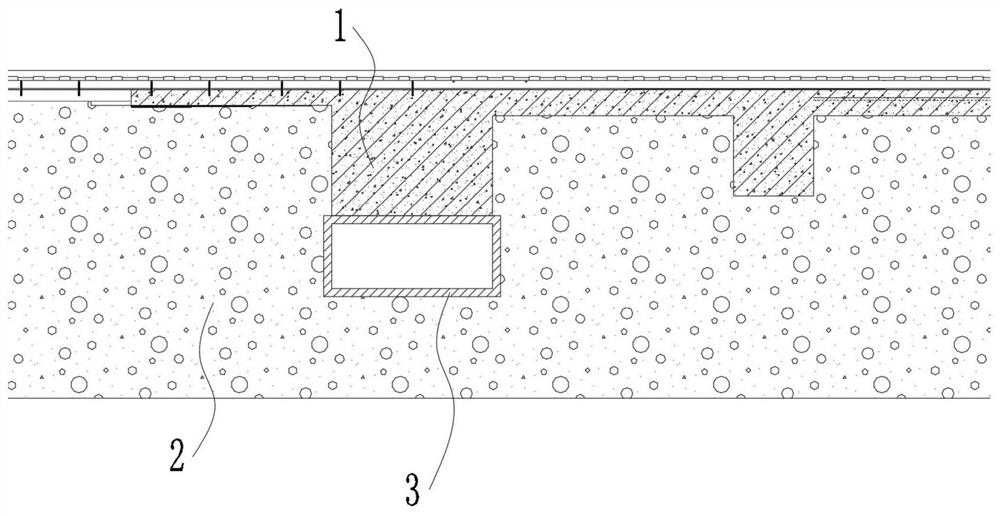

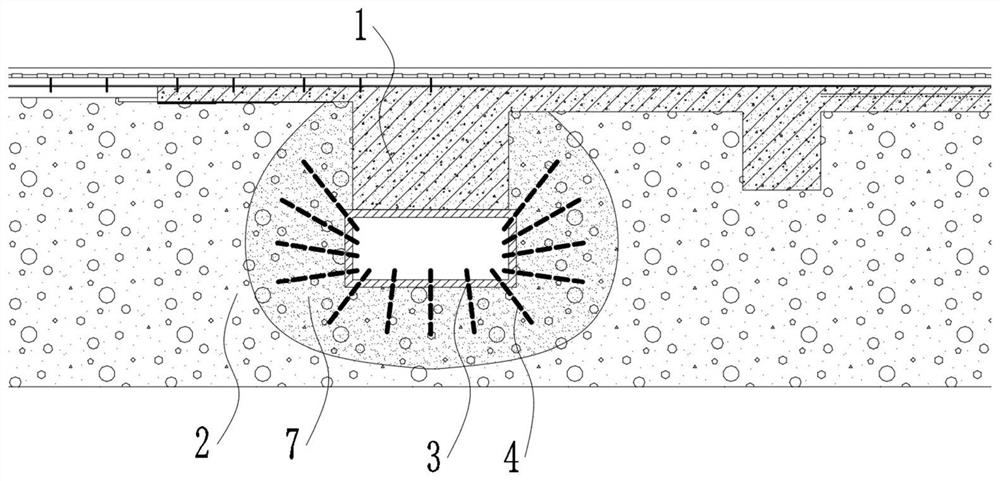

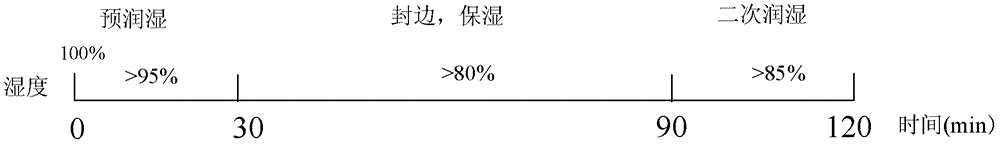

Cement asphalt mortar used for high temperature complicated work condition, and preparation method and construction method thereof

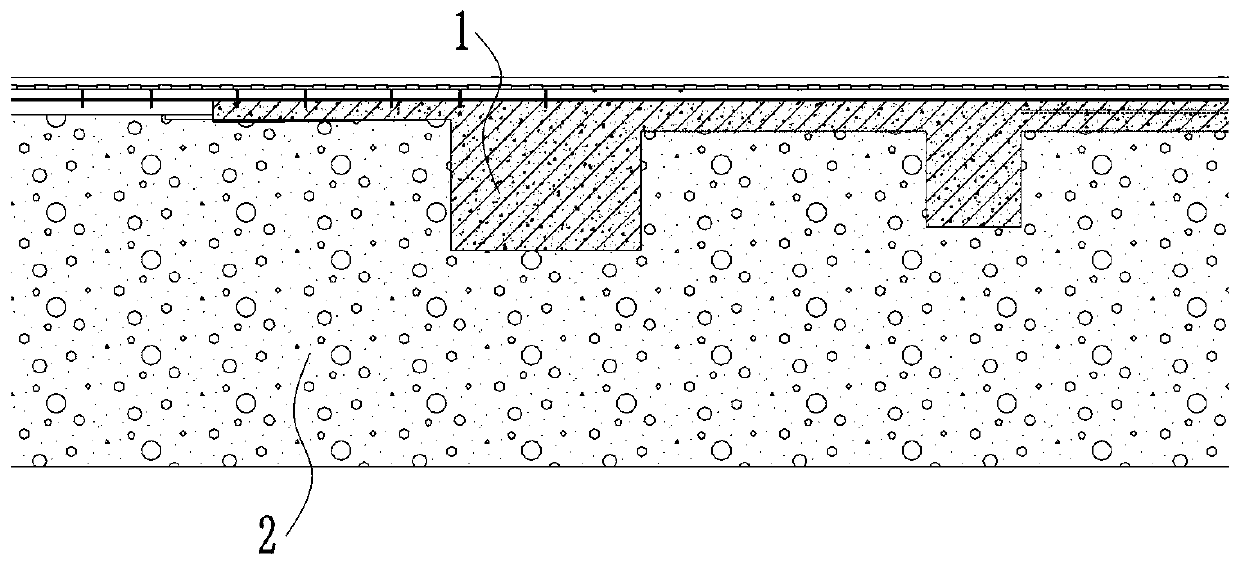

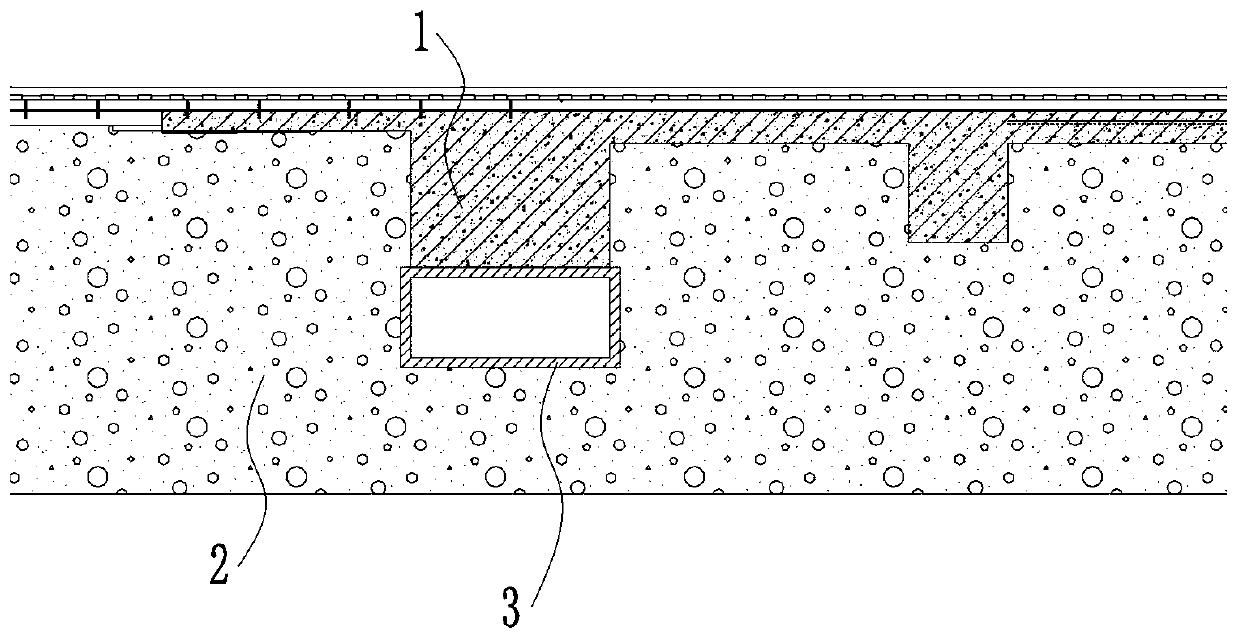

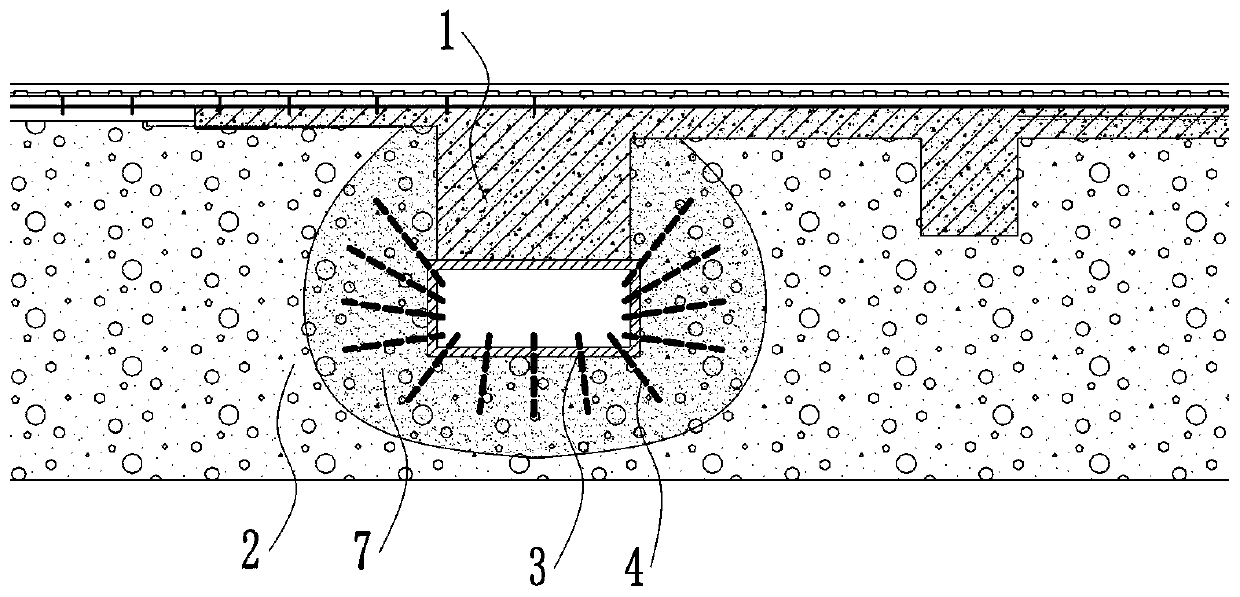

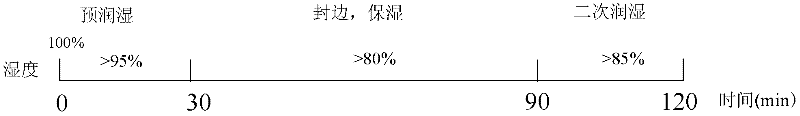

ActiveCN102503296AFull of perfusionSolve the problem of difficult perfusionRailway track constructionWater reducerMaterials science

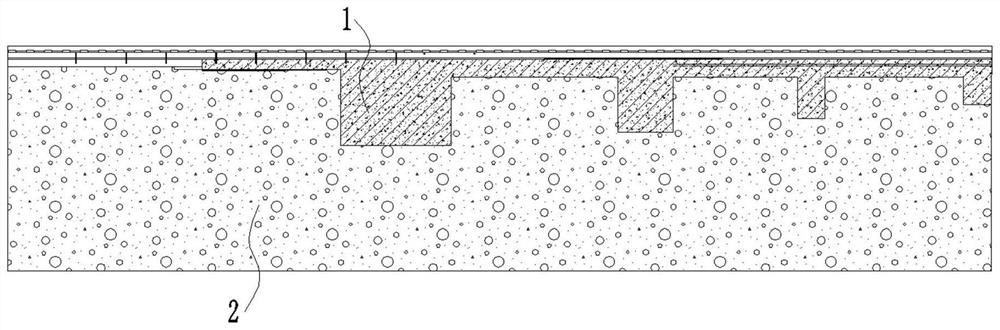

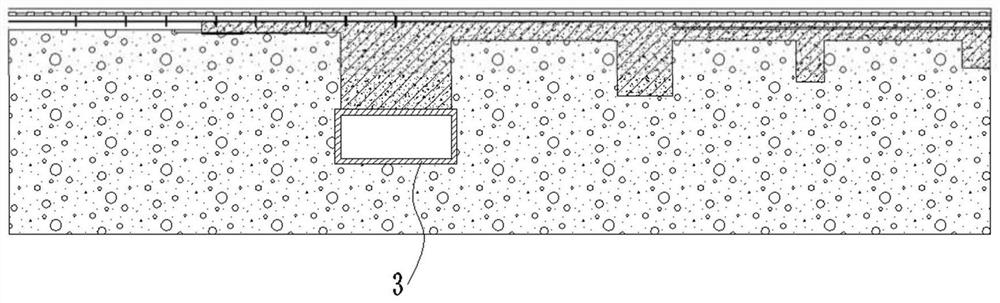

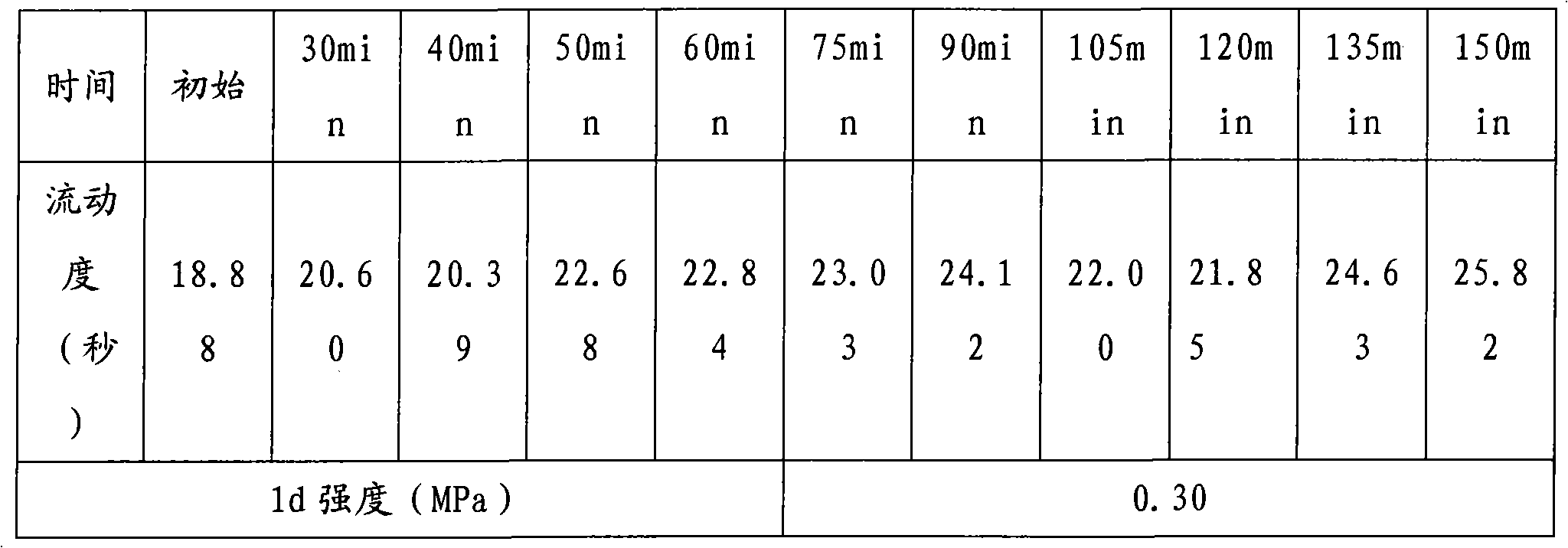

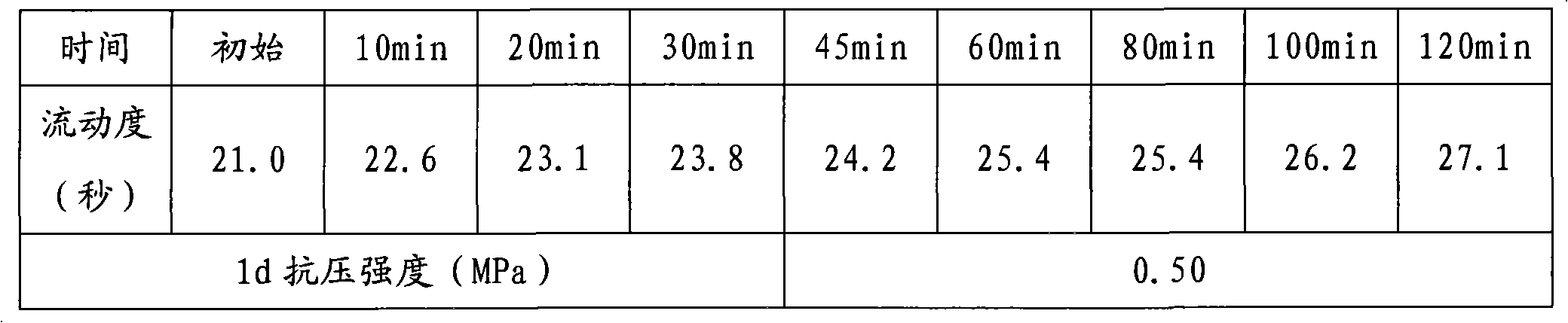

The invention relates to a building material, and a preparation method and a construction method of the building material. A cement asphalt mortar used for high temperature complicated work condition is prepared from raw materials including cement, fine aggregate, expansion admixture, powdered aluminum, emulsified asphalt with high cement adaptability, water, high-efficiency set-retarding type water-reducer and foam suppressor; the weight part of each component is as follows: cement 100 parts, fine aggregate 135-175 parts, expansion admixture 10-15 parts, powdered aluminum 0.002-0.005 parts, emulsified asphalt 40-50 parts, water 20-40 parts, water-reducer 0.8-1.2 parts and foam suppressor 0.03-0.08 part; pre-wetting technology and grouting technology matched with high temperature weather are used; the working property of the mortar is good at high temperature of 30-40 degrees centigrade, the construction process is accurately controlled, the mortar grouting is full, the quality defects such as through hole and large air bubble and cavity are inexistent after de-molding; the size of the surface air bubble area is less than 1%, and the 1-3cm air bubble area is less than 0.05%. The invention solves the problems of too large loss of working property of cement asphalt mortar at high temperature and difficulty of mortar grouting during construction.

Owner:WUHAN UNIV OF TECH

End thorn area reinforcing structure and construction method

ActiveCN111535078AIncrease frictional resistanceIncrease the anchoring force of the end thornBallastwayRebarSelf-consolidating concrete

The invention discloses an end thorn area reinforcing structure and a construction method. The end thorn area reinforcing structure comprises n-shaped end thorns; a first shield steel wall is horizontally arranged below main end thorns of the n-shaped end thorns, and the top of the first shield steel wall is connected with bottoms of the main end thorns through implanted reinforcing ribs; a secondshield steel wall and a third shield steel wall are arranged on a left side and a right side of the first shield steel wall, and reinforcing meshes are woven in the first shield steel wall, the second shield steel wall and the third shield steel wall and permeation-expansion type self-compacting concrete is filled; and the reinforcing meshes and the reinforcing ribs in the first shield steel wall, the second shield steel wall and the third shield steel wall are connected into a whole. According to the end thorn area reinforcing structure, the n-shaped end thorns are connected with the first shield steel wall, the second shield steel wall and the third shield steel wall through the reinforcing ribs, the reinforcing meshes and the permeation-expansion type self-compacting concrete, the original n-shaped end thorns are changed into inverted T-shaped end thorns, a track structure and a roadbed are well fixed together, and a reinforcing effect is better achieved.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Cement mortar and its method for preparing rapid open traffic semi-flexible pavement

ActiveCN103553511BImprove early strengthMeet the needs of long-distance transportationIn situ pavingsBridge engineeringSodium Bentonite

Owner:JIANGSU SOBUTE NEW MATERIALS +1

A rapid repair method of cement emulsified asphalt mortar for unit slab ballastless track

ActiveCN104480815BGuaranteed smoothnessGuaranteed operational safetyRailway track constructionComing outCement mortar

The invention relates to a method for rapidly repairing cement emulsified asphalt mortar interface connection damage of a unit slab ballastless track; the method mainly comprises the steps of cleaning, sealing, setting of grouting openings, interface connection damage grouting and edging treatment; the specific steps are as follows: firstly, cleaning dust and impurities around a mortar interface connection damage; secondly sealing the interface connection damage area, setting the grouting openings and placing a dial indicator at four corners of a track slab in a to-be-repaired area; thirdly, connecting a dual-component self-mixing grouting machine with a pressure grouting hose, and injecting a dual-component grouting material to the grouting openings in sequence; after the mortar comes out of a grouting opening having the spacing of more than the width of the track slab with the next grouting openings, turning to the next grouting opening to grout continuously till the whole cement emulsified asphalt mortar seam area is fully grouted; and finally, cutting the grouting hose, polishing sealed materials to finish the repairing. The method has the characteristics of simple and rapid process, high repairing efficiency and capability of realizing rapid repairing within skylight time and is applicable to repairing the cement emulsified asphalt mortar seams of the unit slab ballastless track.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Preparation method of asphalt pavement crevice embedding sealing material

InactiveCN101235207BReduce pollutionAvoid it happening againPaving detailsBuilding insulationsPolymer scienceRoad surface

Owner:陕西长大博源公路养护科技有限公司

A kind of reinforcement structure and construction method of end thorn area

ActiveCN111535078BImprove liquidityHigh volume expansionBallastwayArchitectural engineeringMesh reinforcement

The invention discloses a reinforcement structure and a construction method for an end thorn area, comprising: Π-shaped end thorns; a first shield steel wall is horizontally arranged below the main end thorns of the Π-shaped end thorns, and the top of the first shield steel wall is connected to the The bottom of the main thorn is connected by implanted high-strength steel bars; the left and right sides of the first shield steel wall are provided with the second shield steel wall and the third shield steel wall, the first shield steel wall, the second shield steel wall Both the steel wall of the shield tunnel and the steel wall of the third shield tunnel are woven with steel mesh and filled with permeable and expansive self-compacting concrete; Connected with high-strength steel bars as a whole. The reinforcement structure of the end thorn region of the present invention connects the Π-shaped end thorns with the first shield steel wall, the second shield steel wall, and the third shield steel wall through high-strength steel bars, steel mesh and seepage-expandable self-compacting concrete, The original Π-shaped end thorn is changed into an inverted T-shaped end thorn, so that the track structure and the roadbed are well fixed together, which is more conducive to reinforcement.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Method for preparing emulsified asphalt slurry

ActiveCN101642933BEasy to prepareQuality improvementSolid waste managementMixing operation control apparatusEmulsionGas phase

The invention discloses a method for preparing emulsified asphalt slurry. The emulsified asphalt slurry is formed by mixing and stirring emulsified asphalt, artificial sand, water, 40-50% acrylic emulsion, sweller, air entraining agent, defoaming agent and aluminum powder; the emulsified asphalt is formed by mixing emulsified asphalt 1# intermediate product and emulsified asphalt 2# intermediate product, adding stabilizer gas silica and evenly mixing; the emulsified asphalt 1# intermediate product is formed by mixing and grinding 1# emusifier prepared by adding water to asphalt, lignose, alkylamine, gas phase silica and polyoxyethylene derivative; and the emulsified asphalt 2# intermediate product is formed by mixing and grinding 2# emusifier prepared by adding water to asphalt, volcanic type amargosite. The emulsified asphalt slurry of the invention is high in strength, plump in pouring, simple in preparation method, low in raw material cost and perfect in construction performance.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Emulsified asphalt and preparation method thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

Matrix asphalt mixture gradation applicable to semi-flexible asphalt roads

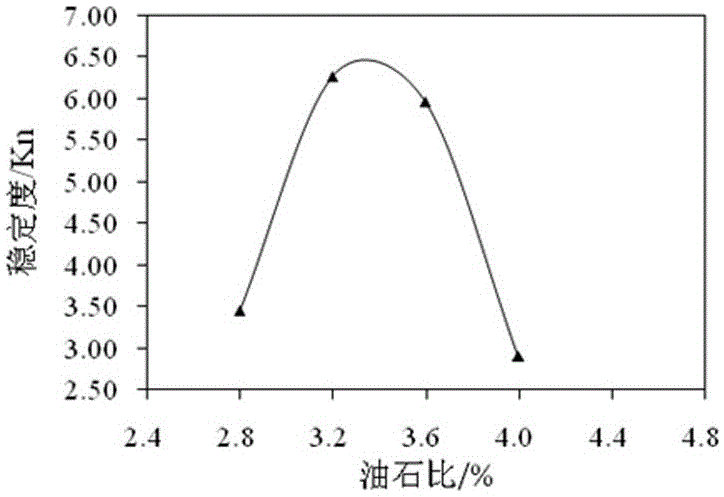

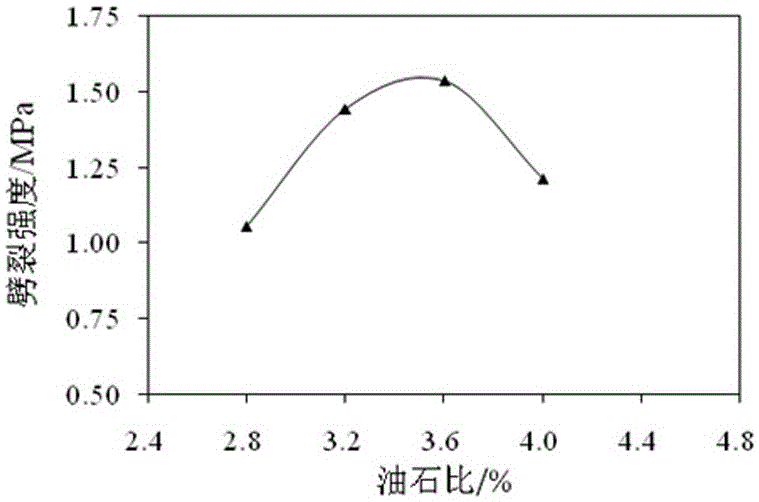

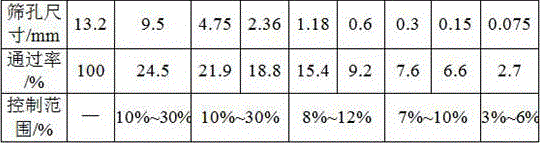

The invention belongs to the technical field of pavement materials in highway engineering and particularly relates to matrix asphalt mixture gradation applicable to semi-flexible asphalt roads. Matrix asphalt mixture aggregates are prepared to form matrix asphalt mixtures being 2.8%, 3.2%, 3.6% and 4.0% in asphalt-aggregate ratio respectively; stability or splitting strength are taken as indexes for measurement of stability and splitting strength of the matrix asphalt mixtures under different asphalt-aggregate ratios; a relation curve of between the asphalt-aggregate ratios and the stability and splitting strength of the matrix asphalt mixtures is further drawn, and the asphalt-aggregate ratio at a peak is taken as an optimal asphalt-aggregate ratio of the matrix asphalt mixtures. The matrix asphalt mixture gradation applicable to the semi-flexible asphalt roads has the advantage of high stability.

Owner:SHANXI PROVINCIAL RES INST OF COMM

Anti-freezing emulsified asphalt and preparation method thereof

ActiveCN103059581BImproved sieve residueGood storage stabilityBuilding insulationsPolymer scienceAlcohol

The invention discloses an anti-freezing emulsified asphalt and a preparation method thereof. A formula of the emulsified asphalt comprises asphalt, an anionic emulsifier, a cationic emulsifier, a thickener, a stabilizer, a water reducing agent, alcohol and water. The method provided by the invention comprises steps of: dissolving the water reducing agent and the thickener in alcohol at room temperature to prepare a paste, and adding a defoaming agent into the paste; and then participating the paste in the emulsion as a whole. The paste is combined with the cationic emulsifier and the anionic emulsifier emulsifier, so as to reduce usage amount and cost of emulsifier, and obviously improve sieve residue, storage stability, cement miscibility and frost resistance of the emulsified asphalt.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for rapid repair of high-speed railway ballastless track

ActiveCN106868959BEfficient repairEffective maintenanceBallastwayRailway track constructionSurface layerLong term durability

The invention belongs to the technical field of high-speed railway ballastless track repairing and provides a high-speed railway ballastless track line rapid repairing method in order to solve the problem that at present, a complete set of effective, rapid and systematic repairing method is not available for existing high-speed railway ballastless track lines. The high-speed railway ballastless track line rapid repairing method comprises the steps of line-to-line physical isolator installation, track sawing and moving, integral concrete track bed cutting and transporting, subgrade bed surface layer graded broken stone measurement leveling, supporting layer construction, track bed slab construction, steel track welding locking, track fine adjustment, road shoulder waterproof and drainage engineering and related engineering installation; line-to-line physical isolator demolition, line-to-line sealing layer and related engineering recovery, steel track polishing derusting, line-to-line waterproof construction, and drainage side ditch and side ditch platform recovery construction. Implementation is easy, and the high-speed driving requirement is met after repairing; the repairing and reinforcement effect is good, and the situation that a problem happens again to a ballastless track is effectively prevented; and the high-speed railway ballastless track is efficiently, rapidly, completely, systematically and comprehensively repaired and maintained, so that the safety of railway operation and the long-term durability of the structure of the ballastless track are ensured.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

A structure and construction method for enhancing the anchoring force of end thorns

ActiveCN111535079BIncrease anchoring forceReduced longitudinal displacementBallastwayAdhesive cementTrackway

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Cement asphalt mortar used for high temperature complicated work condition, and preparation method and construction method thereof

ActiveCN102503296BFull of perfusionSolve the problem of difficult perfusionRailway track constructionWater reducerMaterials science

The invention relates to a building material, and a preparation method and a construction method of the building material. A cement asphalt mortar used for high temperature complicated work condition is prepared from raw materials including cement, fine aggregate, expansion admixture, powdered aluminum, emulsified asphalt with high cement adaptability, water, high-efficiency set-retarding type water-reducer and foam suppressor; the weight part of each component is as follows: cement 100 parts, fine aggregate 135-175 parts, expansion admixture 10-15 parts, powdered aluminum 0.002-0.005 parts, emulsified asphalt 40-50 parts, water 20-40 parts, water-reducer 0.8-1.2 parts and foam suppressor 0.03-0.08 part; pre-wetting technology and grouting technology matched with high temperature weather are used; the working property of the mortar is good at high temperature of 30-40 degrees centigrade, the construction process is accurately controlled, the mortar grouting is full, the quality defects such as through hole and large air bubble and cavity are inexistent after de-molding; the size of the surface air bubble area is less than 1%, and the 1-3cm air bubble area is less than 0.05%. The invention solves the problems of too large loss of working property of cement asphalt mortar at high temperature and difficulty of mortar grouting during construction.

Owner:WUHAN UNIV OF TECH

Anti-freezing cement asphalt mortar and preparation method thereof

The invention discloses an anti-freezing cement asphalt mortar and a preparation method thereof. The cement asphalt mortar comprises emulsified asphalt, cement, fine sand, an expansive agent, an aluminite powder and water. A formula of the emulsified asphalt comprises asphalt, an anionic emulsifier, a cationic emulsifier, a thickener, a stabilizer, a water reducing agent, a defoaming agent, alcohol and water. The cement asphalt mortar provided by the invention employs special emulsified asphalt; and when the cement asphalt mortar is mixed with dry material such as cement and sand, the water reducing agent and the defoaming agent are easily dispersed to fully contact with the dry material, thus realizing obvious water reducing effect, effectively avoiding bleeding phenomenon after pouring of CA mortar, and improving workability of the emulsified asphalt with cement and fine sand; and synergistic effect of alcohol improves anti-freezing performance of the CA mortar, effectively eliminates large bubbles, and realizes dense and uniform texture after forming of the CA mortar. The cement asphalt mortar provided by the invention is particularly suitable for perfusion under track plate as a buffer layer in construction of high-speed railway.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of modified emulsified asphalt and preparation method thereof

ActiveCN103804930BImproved sieve residueGood storage stabilityBallastwayBuilding insulationsAlcoholEmulsion

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of cement asphalt mortar and preparation method thereof

The invention discloses a cement asphalt mortar and a preparation method thereof. The cement asphalt mortar includes emulsified asphalt, cement, fine sand, expansion agent, aluminum powder and water. The formula of emulsified asphalt includes asphalt, cationic emulsifier, anionic emulsifier, thickener, stabilizer, water reducer, defoamer, and water. The cement asphalt mortar of the present invention adopts special emulsified asphalt. When it is mixed with dry materials such as cement and fine sand, the water reducer and defoamer are easily dispersed evenly, fully contacted with dry materials, and the water reducing effect is obvious. At the same time, it can effectively avoid the bleeding phenomenon after CA mortar pouring, improve the workability of emulsified asphalt, cement and fine sand, improve the fluidity of CA mortar, and effectively eliminate large air bubbles, making CA mortar After molding, the texture is dense and uniform. The cement asphalt mortar of the present invention is particularly suitable for pouring under track slabs as a shock-absorbing buffer layer when building high-speed railways.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com