Matrix asphalt mixture gradation applicable to semi-flexible asphalt roads

A technology for asphalt mixture and asphalt pavement, applied in the field of master asphalt mixture grading, can solve the problems of poor stability and low filling rate of asphalt mixture, achieve high stability value, full filling, and avoid road surface particles drop. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following content is only a preferred embodiment of the present invention, and does not limit the present invention in any form; without departing from the content of the technical solution of the present invention, any simple modifications, equivalent changes and modifications all belong to the technical solution of the present invention In the range.

[0013] (1) Take representative samples from each ore silo actually used in the project, and pass the indoor screening test to obtain the gradation of each silo.

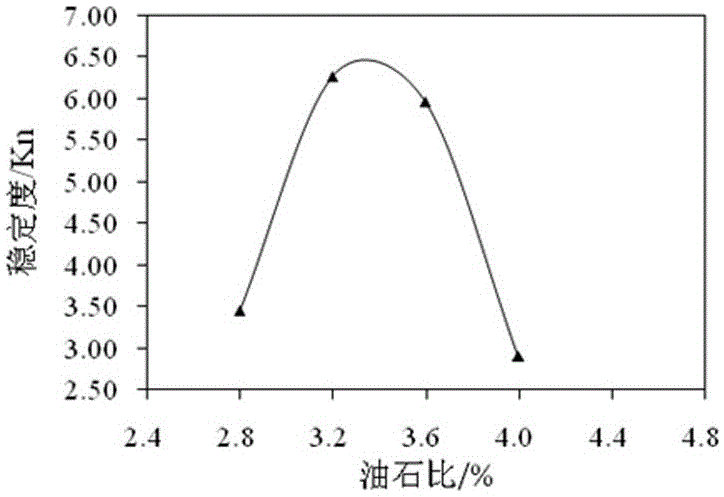

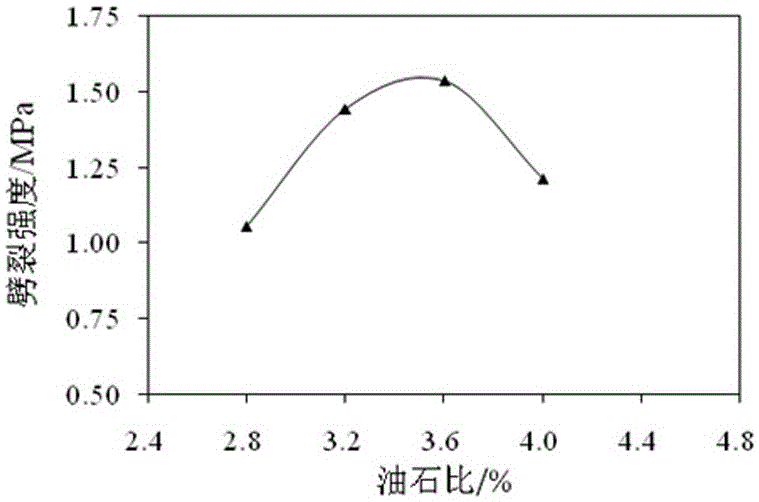

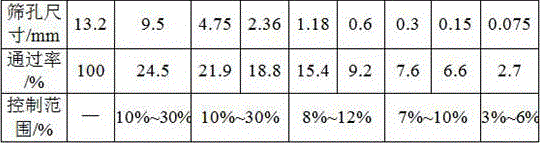

[0014] (2) Determine the blending ratio of mineral materials in each silo by trial blending method, and its synthetic gradation is shown in Table 1. The synthetic gradation of the parent asphalt mixture involved in Table 1 is not the optimal gradation of the parent asphalt mixture, but only the synthetic gradation after the blending ratio is determined according to the mineral material gradation of each silo in the actual project of this embodiment.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com