A kind of cement asphalt mortar and preparation method thereof

A technology of cement asphalt and mortar, which is applied to the field of cement asphalt mortar poured under slab ballastless track slab when building high-speed railway and its preparation field, can solve the problems of difficult emulsification of modified asphalt, affecting the curing time of mortar, and strict equipment requirements. , to widen the operating temperature range, the water reduction and defoaming effects are obvious, and the frost resistance is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

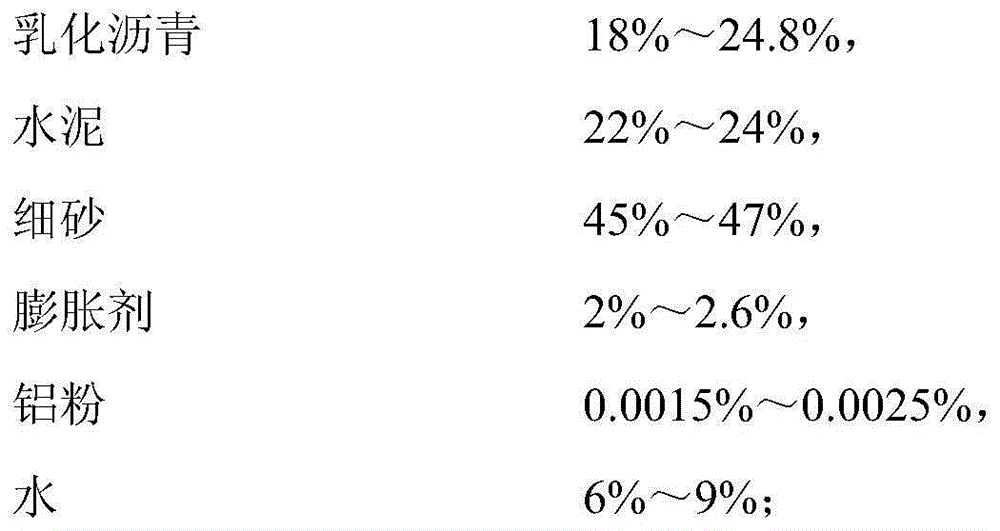

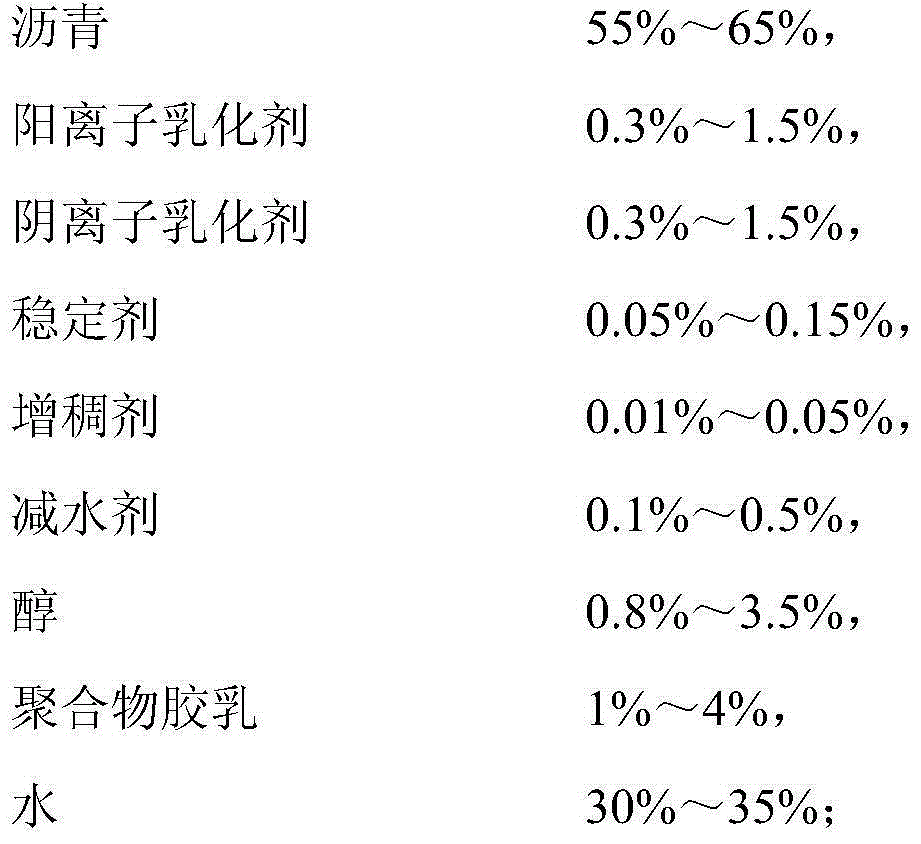

Method used

Image

Examples

Embodiment 1

[0051] Take 6470g of Liaohe crude oil straight-run asphalt with a penetration of 108 (1 / 10mm), heat it to 115°C for later use, and obtain material I; at room temperature, add 10g of calcium lignosulfonate and 7g of methyl silicone oil , 80g of isopropanol, after mixing evenly, slowly add 1g of carboxymethylcellulose in a stirring state, stir fully to make a paste, and obtain material II; Ammonium 30g, anionic emulsifier fat (18) alcohol polyoxyethylene (3) sodium ether sulfate 30g, zwitterionic emulsifier N-cocoyl-β-alanine sodium 10g, nonionic emulsifier oleyl alcohol poly 10g of oxyethylene (20) ether and 5g of calcium chloride were dissolved in 3247g of water together, and the temperature was kept at 45°C to obtain material III; 100g of styrene-butadiene latex with a concentration of 60% was accurately weighed as material IV; then material I, material II, material III, and material IV are transported to the colloid mill respectively, and after being uniformly dispersed by t...

Embodiment 2

[0053] Take 6000g of Oman crude oil solvent deoiled asphalt from Maoming Petrochemical Company with a penetration of 98 (1 / 10mm), heat it to 125°C for later use, and obtain material I; Oxypropylene glycerin (GPE30) 5g, ethanol 60g, tert-butanol 100g, after mixing evenly, slowly add carboxyethyl cellulose 5g under stirring state, fully stir evenly to make a paste, and obtain material II; cationic emulsification Agent octadecyltrimethylammonium chloride 125g, anionic emulsifier fatty (18) amine polyoxyethylene (4) sodium sulfate 55g, zwitterionic emulsifier N-tallow-β-iminodipropionic acid 69g of disodium, 50g of non-ionic emulsifier octylphenol polyoxyethylene (20) ether, and 15g of ammonium chloride were dissolved in 3276g of water, stirred well, prepared into soap liquid and kept at 65°C to obtain material III Accurately take by weighing 200g concentration is the chloroprene latex of 55% as material IV; Then material I, material II, material III, material IV are transported i...

Embodiment 3

[0055] Take 5900g of Kuwait crude oil oxidized asphalt from Qilu Petrochemical Company with a penetration of 62 (1 / 10mm), and heat it to 155°C to obtain material I; (C18, concentration 30wt%) 9g, propanol 320g, after fully mixing evenly, slowly add 3g of hydroxyethyl cellulose under stirring state, stir well to make a paste, and obtain material II; take cationic emulsifier ten Dialkyltrimethylammonium bromide 55g, anionic emulsifier sodium lauryl sulfate 90g, zwitterionic emulsifier N-lauryl-β-alanine 30g, nonionic emulsifier lauryl alcohol polyoxyethylene (20) 30g of ether and 10g of magnesium chloride were dissolved in 3278g of water at 55°C, stirred well, prepared into a soap solution and kept at a temperature of 55°C to obtain material III; accurately weighed 250g of nitrile latex with a concentration of 50% as Material IV; then material I, material II, material III, and material IV are respectively transported to the colloid mill, and after being uniformly dispersed by th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com