Method for repairing and reinforcing open joint of filling layer of slab ballastless track

A technology of slab ballastless track and filling layer, which is applied in the direction of track, track laying, track maintenance, etc., to achieve good permeability, prevent recurrence, and have good repair and reinforcement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

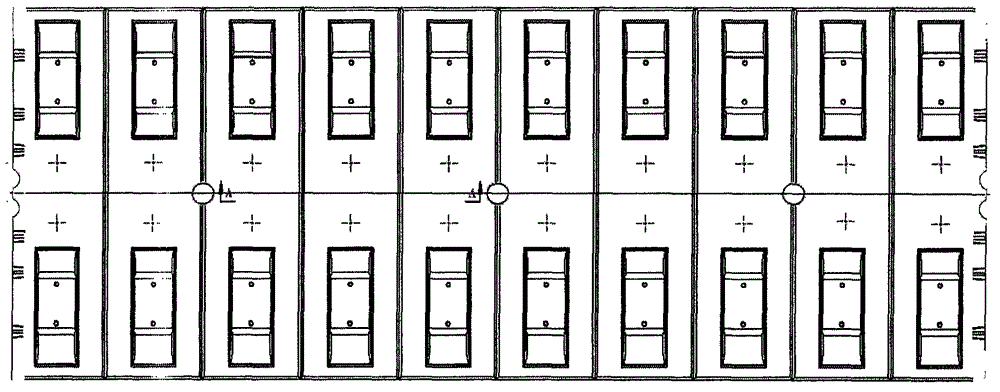

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] A method for repairing and reinforcing the gaps in the filling layer of a slab ballastless track structure described in this embodiment includes the following steps:

[0027] 1) Drilling holes vertically on the track surface in the separation zone of the filling layer;

[0028] 2) Anchoring at the drilling position on the track surface;

[0029] 3) Grouting repair for the fractured area of the filling layer.

[0030] Step 1): Determine the number of drilling holes in the track slab in the separation area of the filling layer according to the separation of the filling layer of the track slab. The number of drilling holes can refer to the following standards:

[0031] a) When the gap width of the track plate is greater than 8mm, 20 holes can be drilled, that is, holes are drilled on each rail platform;

[0032] b) When the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| curing time | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com