High-speed railway ballastless track line rapid repairing method

A ballastless track and line technology, which is applied to roads, tracks, laying tracks, etc., can solve the problems of high-speed rail ballastless track lines without a complete set, effective and fast system repair methods, etc., achieve good repair and reinforcement effects, solve unevenness, Guaranteed safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

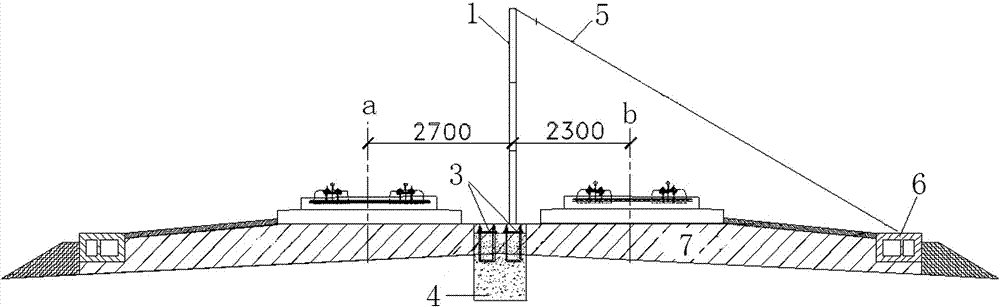

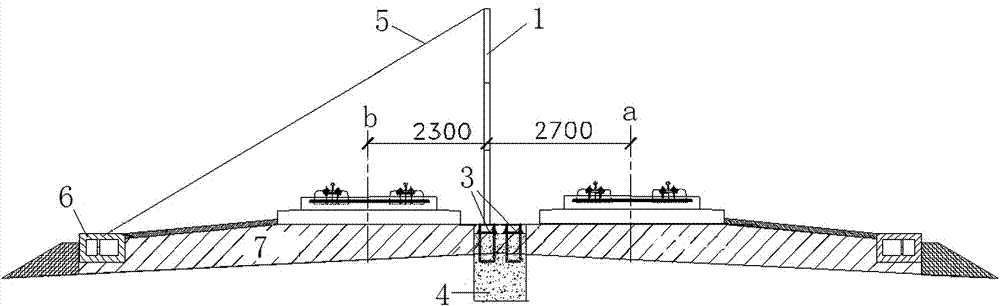

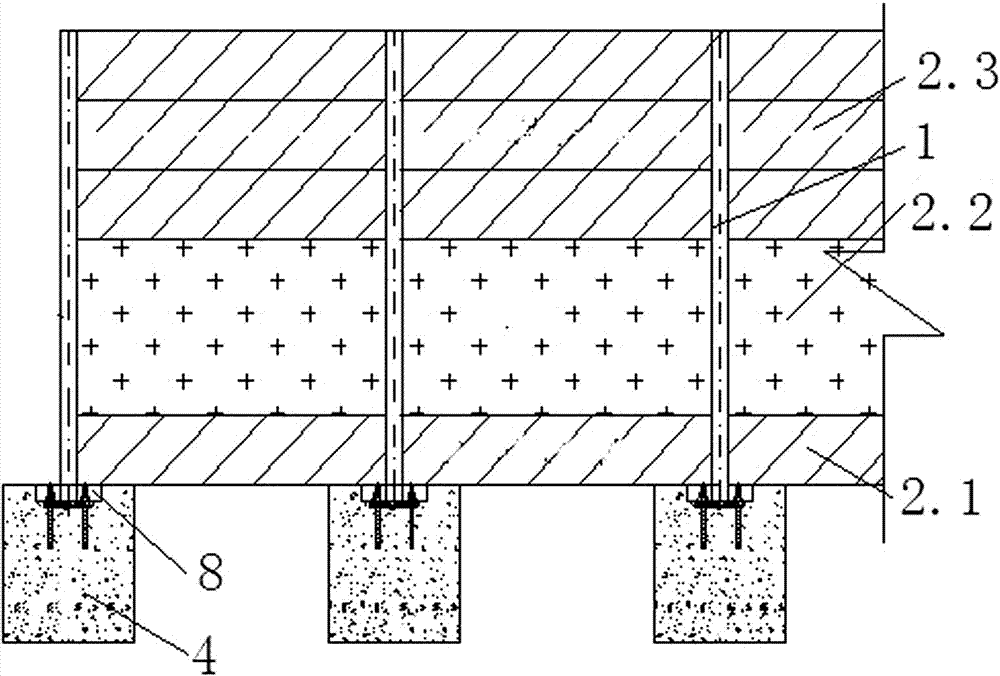

[0030] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0031] For the remediation and restoration of a high-speed railway section undertaken by the applicant, the original design slope was adjusted from 6.9‰ to 6.86605‰, and the track bed slab and base layer with the rail bearing groove still arching more than 2mm and the height adjustment exceeding 20mm after slope adjustment were removed, and the original design slope was adjusted from 6.9‰ to 6.86605‰. Construction of ballastless track (before and after the clearing section of the ballast bed, the rail surface elevation must be adjusted to the design elevation after the track slope adjustment through fasteners). The designed ballastless track adopts CRTSⅡ type double-block sleepers, adopts WJ-8 fasteners, the base layer and the track bed slab are respectively made of C25 and C40 concrete, and two layers of steel bars are set up, and the base layer is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com