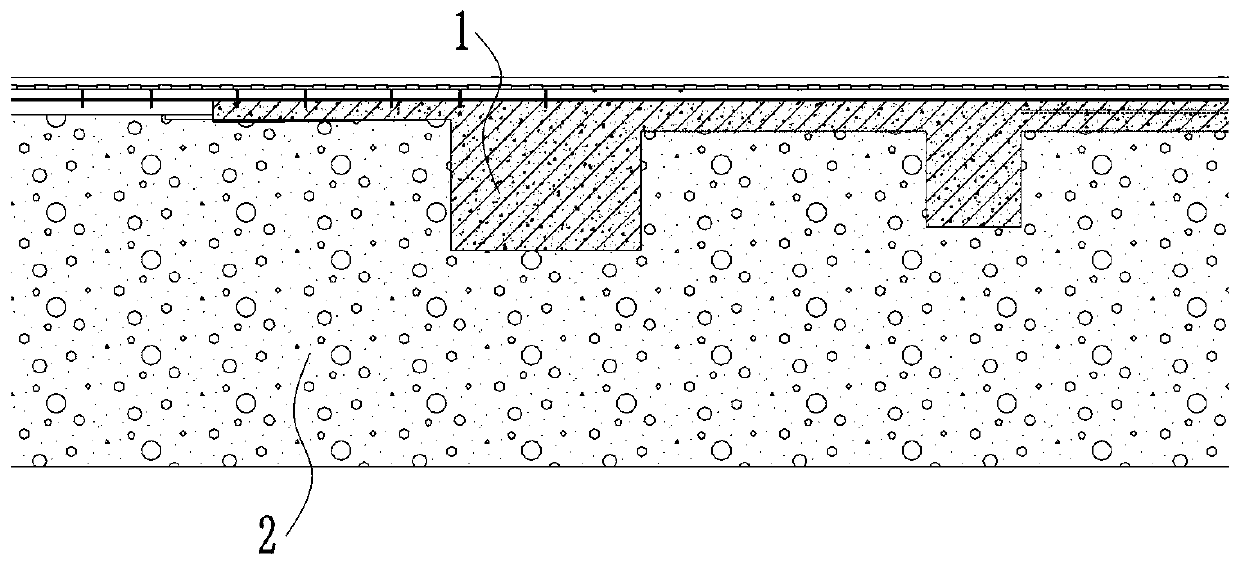

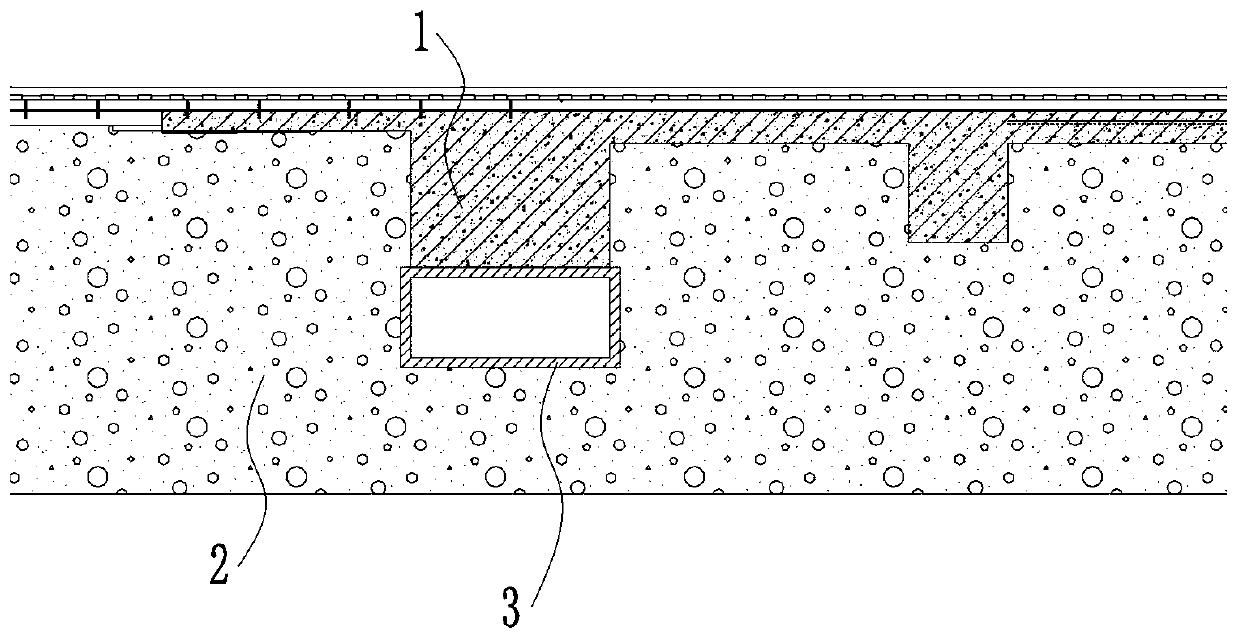

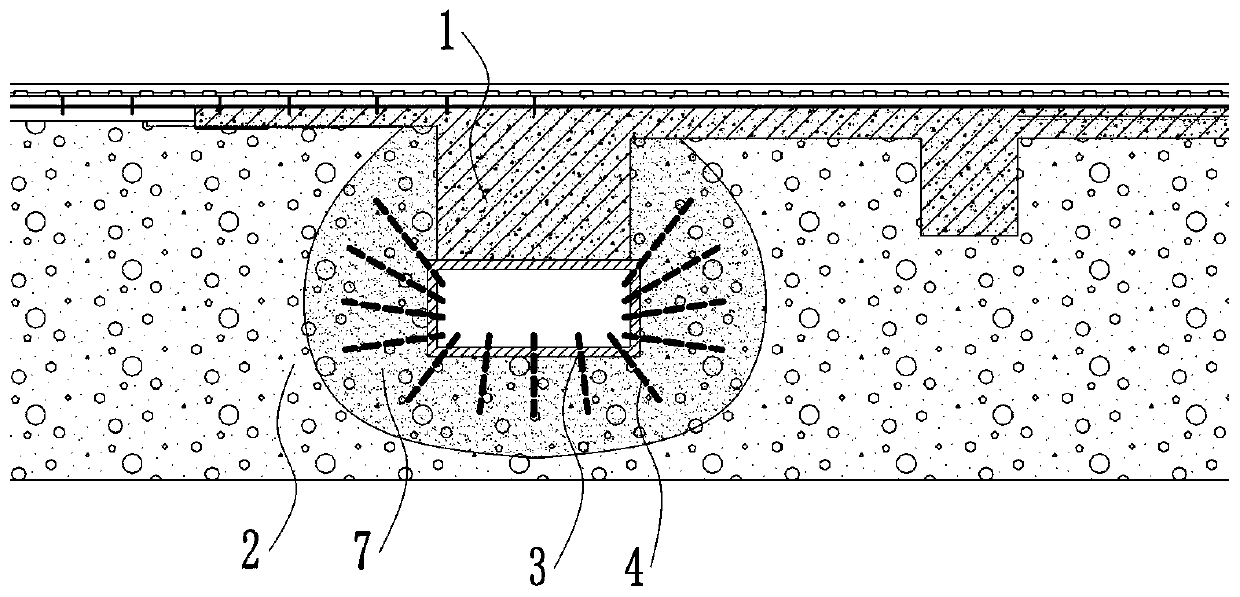

End thorn anchor force enhancing structure and construction method

A technology for strengthening structures and construction methods, applied in the directions of roads, tracks, ballast layers, etc., can solve the problems of track structure movement and insufficient anchoring force of Π-shaped end barbs, and achieve the effect of increasing anchoring force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070] Step 1. Monitor track deformation:

[0071] Use a high-precision level to measure the track elevation, use a total station to measure the track centerline, and record the data. The geometric deformation of the track before and after construction renovation is within the allowable range;

[0072] Step 2. Unearth the shield:

[0073] The lower part of the main end thorn close to the Π-shaped end thorn, the maximum distance shall not exceed 50mm; on the side of the roadbed, use a 1.5m high, 4m wide 4m pipe wall for the jacking of reinforced concrete with a thickness of 5cm to carry out shield tunneling, chisel in and out of the soil, and clean up the chiseled holes in time Soil;

[0074] Step 3. Shield wall grouting:

[0075] Continue to advance the shield under the end thorn, with a depth of 9m. Use a rock drill to drill holes in the shape of a plum blossom on both sides and bottom of the shield pipe wall, and the depth of the grouting hole is 1m to 1.5m; insert the sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com