Method for preparing emulsified asphalt slurry

A technology for emulsification of asphalt and mortar, applied in the field of mortar, can solve the problems of in-depth research and unsatisfactory construction performance, and achieve the effects of no particles in appearance, increased strength, and improved workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1), Preparation of No. 1 intermediate product: add 50kg lignin, 65kg alkylamine, 70kg nonylphenol polyoxyethylene ether, and 25kg fumed silica into 4800kg of warm water at 65°C, stir and dissolve, and add appropriate amount of hydrochloric acid to adjust The pH value is 2-3 to form the No. 1 emulsion. The No. 90 petroleum pitch at 150°C and the No. 1 emulsion are sent to the high-speed grinding emulsifier in a ratio of 6:4. The pump pressure of the emulsifier is controlled at 0.1-0.3MPa. Mix and grind to obtain No. 1 intermediate product;

[0029] (2), preparation of No. 2 intermediate product: 280kg volcanic rock type bentonite is added into 4600kg 65 ℃ warm water and fully stirred, and puffed for 4 hours, then add 80kg fumed silica stabilizer, and add appropriate amount of citric acid to adjust the pH value 3-5 to form the No. 2 emulsion, send No. 90 petroleum asphalt at 130°C and No. 2 emulsion into the high-speed shear emulsifier at a ratio of 4.5:5.5, and the pump...

Embodiment 2

[0032] Weigh 4413g of emulsified asphalt prepared in Example 1, add 630g of polymer emulsion, 256g of water, and 1.6g of defoamer, and stir for 30s with a paddle mixer at a speed of about 60rpm;

[0033] After stirring for 30s, at the same speed, put 2837g of cement, 315g of expansion agent, 0.43g of aluminum powder, 6304g of artificial sand and 79g of air-entraining agent into the stirring pot in sequence;

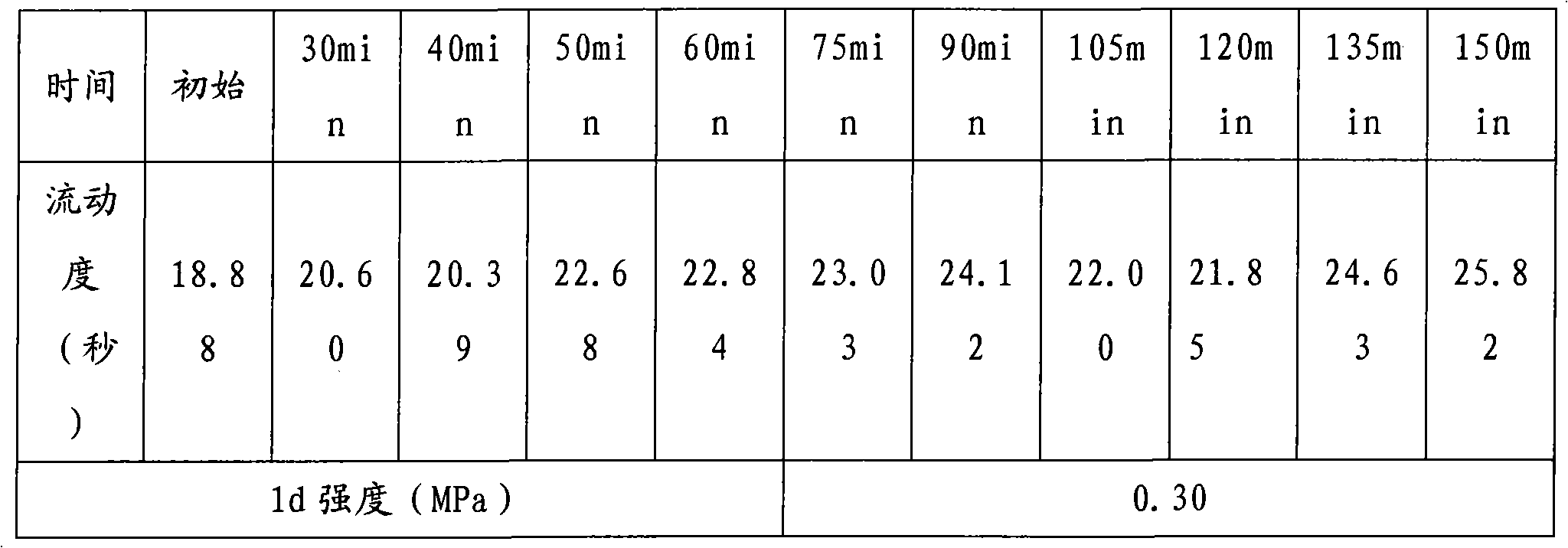

[0034] After all the feeding is completed, adjust the speed of the mixer to 210rpm, and start the high-speed stirring process, and the time is about 3-4min. After completion, indicators such as mortar fluidity and air content can be measured. If the indicators are qualified, samples will be taken for compressive strength testing. The sample size is a φ50mm×50mm cylinder; if the fluidity or air content is insufficient, add water or increase the amount accordingly. High speed mixing time. After the mortar is adjusted to pass the test for 30 minutes, test the fluidity again...

Embodiment 3

[0039] Weigh 543 kg of emulsified asphalt prepared in Example 1, add 16 kg of tap water, 197 g of defoamer, and 78 kg of polymer emulsion, and stir with a turbine mixer at a speed of about 40 rpm;

[0040] After stirring evenly, increase the rotating speed to 100rpm, and put 39kg of expansion agent, 350kg of cement, 776kg of sand, 64g of aluminum powder, and 4.9kg of air-entraining agent into the stirring pot in turn;

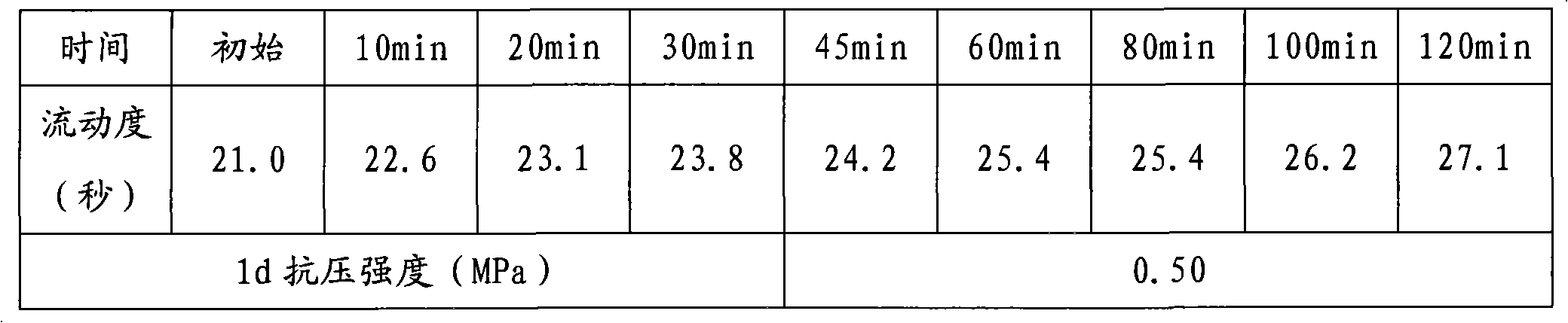

[0041] After all the feeding is completed, adjust the speed of the mixer to 120rpm, and stir at high speed for 5-7 minutes. After the completion, the indicators such as mortar fluidity and air content can be measured. If the indicators are qualified, samples will be taken for compressive strength testing. The sample size is a φ50mm×50mm cylinder; if the fluidity or air content is insufficient, add water or increase the amount accordingly. High speed mixing time. After the mortar is adjusted and qualified, the test is repeated at intervals of 10min-20min to obs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com