Austenitic stainless steel welding wire for high-level waste vitrified body container and its preparation method and application

A technology of austenitic stainless steel and glass solidification, applied in welding equipment, manufacturing tools, welding media, etc., can solve problems such as the inability to meet the welding requirements of containers, and achieve the effect of less defects, cost saving and good process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

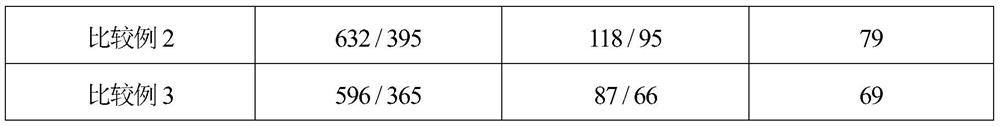

Examples

Embodiment Construction

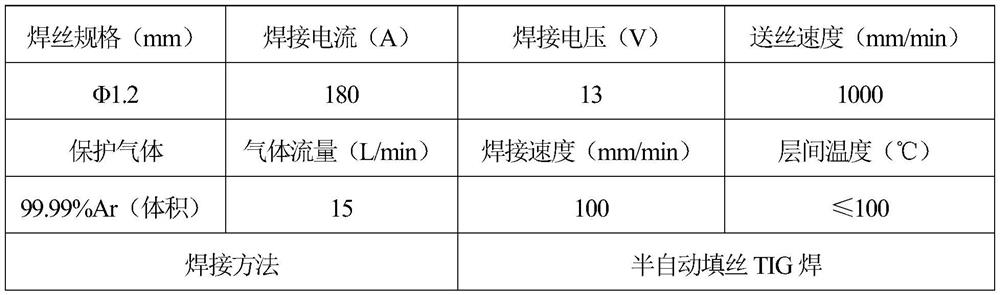

[0021] In a specific embodiment, in the preparation method of the high-temperature-resistant and toughened austenitic stainless steel welding wire for glass solidified containers of the present invention, the master alloy steel ingot prepared by vacuum melting is forged into a billet after being kept at 1150°C for 2 hours; the forged After the billet is kept at 1150°C for 1.5h, it is hot rolled into a Φ6mm wire rod; the wire rod is made into a Φ1.2mm welding wire after continuous cold drawing (intermediate hydrogen charging annealing), and its tensile strength is between 1300 and 1500MPa. In terms of weight percentage, the chemical composition of the austenitic stainless steel welding wire is as follows:

[0022] C: 0.04-0.12%, Cr: 24.0-26.0%, Ni: 19.0-21.0%, Mn: ≤2.0%, Si: ≤1.0%, Nb: 0.3-1.0%, S: <0.001%, P: <0.008 %, O≤0.004%, H≤2ppm, N≤0.1%, Ca: <0.005%, Mg: <0.005%, Ta: <0.02%, Cu: <0.02%, Co: <0.02%, Fe balance.

[0023] During use, the base material is made of 310s stai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com