A surface-modified ultra-fine steel fiber reinforced high-impedance ultra-high performance concrete and its preparation method

A technology of ultra-fine steel fiber and surface modification, applied in the field of building materials, can solve the problems of low impedance, reduce leakage and conduction, increase friction coefficient, and increase surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

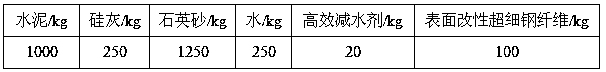

[0019] Specific embodiment 1: This embodiment records a surface-modified ultra-fine steel fiber reinforced high-impedance ultra-high-performance concrete, and the ultra-high-performance concrete includes 50 to 300 parts by mass of surface-modified ultra-fine steel fibers 500-1500 parts of cement, 50-500 parts of mineral admixture, 1000-1800 parts of fine aggregate, 5-40 parts of chemical admixture and 150-650 parts of water.

specific Embodiment approach 2

[0020] Specific embodiment two: a surface-modified ultrafine steel fiber reinforced high-impedance ultra-high-performance concrete described in specific embodiment one, the cement is Portland cement or ordinary Portland cement, and the chemically added The plasticizer is a mixture of plasticizer, plasticizer and expansion agent, plasticizer and air-entraining agent or plasticizer, expansion agent and air-entraining agent. Portland cement is mostly used for quality inspection and calibration, and ordinary Portland cement is mostly used in actual projects. The mixed material content of the former is less than 5%, and the mixed material content of the latter is between 5 and 20%. The mixed material refers to the artificial or natural mineral material added together with clinker and gypsum to improve cement performance, adjust cement grade and increase cement output when grinding cement. Specifically, it can be granulated blast furnace slag, pozzolanic admixture, fly ash, quartzit...

specific Embodiment approach 3

[0021] Embodiment 3: The surface-modified ultra-fine steel fiber reinforced high-impedance ultra-high-performance concrete described in Embodiment 1, the mineral admixture is one of silica fume, fly ash, and granulated blast furnace slag. species or several.

[0022] Embodiment 4: A surface-modified ultra-fine steel fiber reinforced high-impedance ultra-high-performance concrete described in Embodiment 1, the surface-modified ultra-fine steel fiber uses ordinary ultra-fine steel fibers as the fiber matrix, and the surface A layer of nano-silicon dioxide with a thickness of <5000nm and capable of reacting with Portland cement or ordinary Portland cement is grown. The ultra-fine steel fibers as the fiber matrix are ultra-fine steel fibers of various shapes and lengths prepared by various methods such as cutting thin steel wires and steel ingot milling.

[0023] Embodiment 5: The surface-modified ultra-fine steel fiber reinforced high-impedance ultra-high performance concrete de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com