Turbine shaft-end seal device applied to Kalina power circulating system

A circulation system and turbine shaft technology, applied to engine components, machines/engines, and leakage prevention, etc., can solve problems such as reduced sealing capacity, loss of environment, pollution, etc., to reduce steady-state deviation and overshoot, and meet Sealing requirements, the effect of ensuring safe service

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

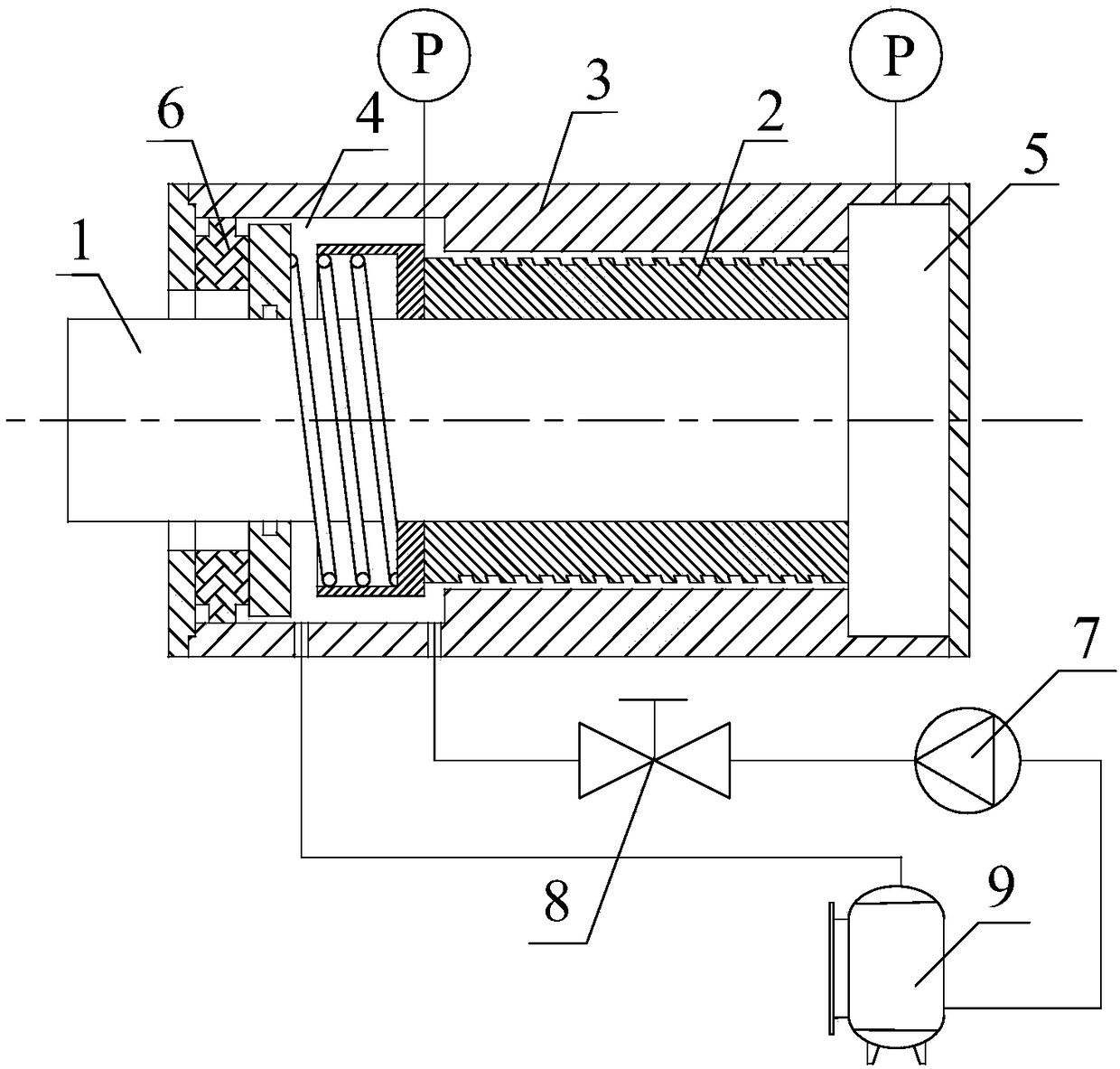

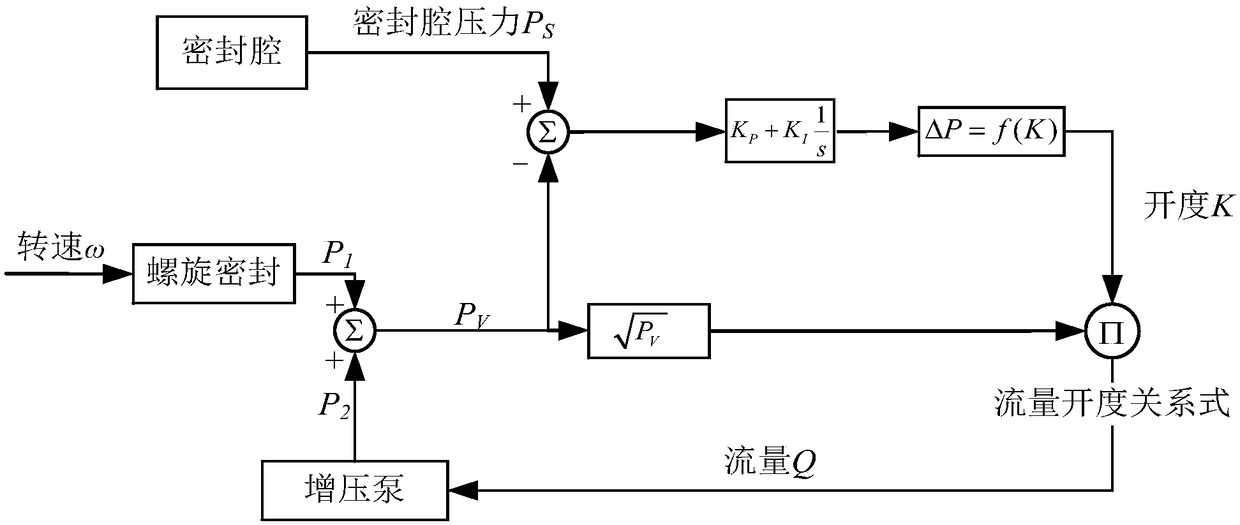

[0023] The present invention is a turbine shaft end sealing device applied to Karina power cycle system, such as figure 1 Shown, including screw seal system, water seal system and booster pump servo control system. Among them: the spiral sealing system includes a spiral shaft sleeve 2, a static sleeve 3, a leakage chamber 4, a sealing chamber 5 and a mechanical seal 6. The water sealing system includes a booster pump 7, a regulating valve 8 and a water tank 9; the booster pump servo control system includes a pressure sensor and a PI controller.

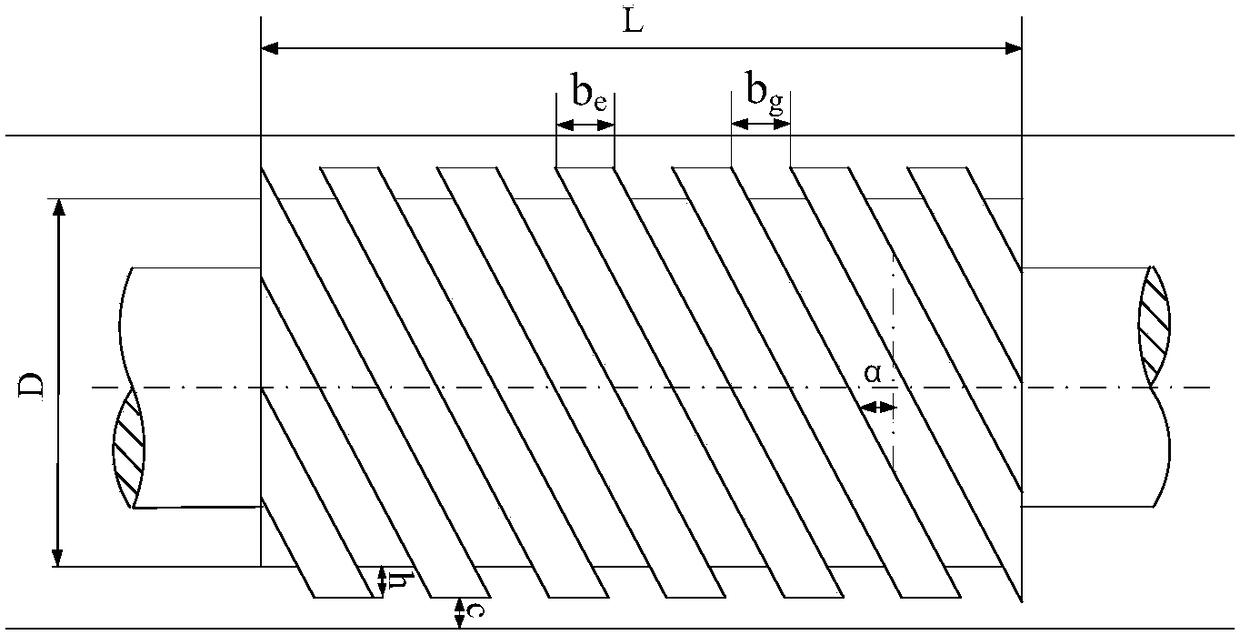

[0024] The spiral bushing 2 is embedded on the main shaft 1 of the Karina power cycle turbine, the static bushing 3 and the spiral bushing 2 keep a certain gap, and are set on the same end of the main shaft 1 to form a spiral seal, and the static bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com