A quick repair material for joints between slabs of crts Ⅱ slab ballastless track

A slab ballastless track and repair material technology, applied in the field of building materials, can solve the problems of high early strength and high strength concrete repair materials, high modulus, wide joint track slab concrete damage, and failure to meet the durability of concrete, etc., to achieve good durability The effect of high resistance, excellent durability, and excellent volume stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

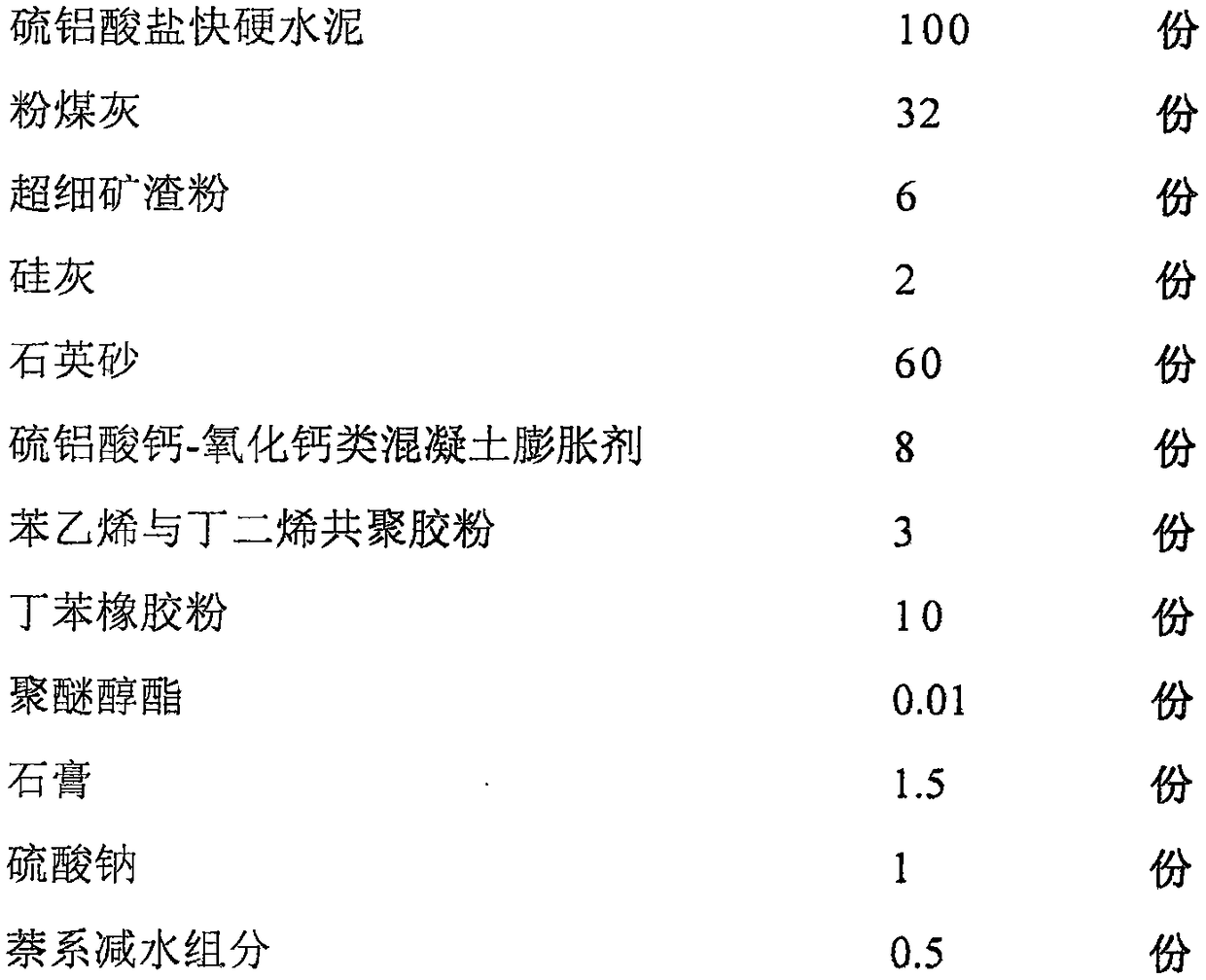

[0026] Restoration materials are counted as:

[0027]

[0028] How to use: Add 100 parts of repair materials, 80 parts of continuous graded coarse aggregate and 16 parts of water to a forced concrete mixer according to the ratio and mix them evenly.

[0029] The main properties are shown in Table 1 below.

Embodiment 2

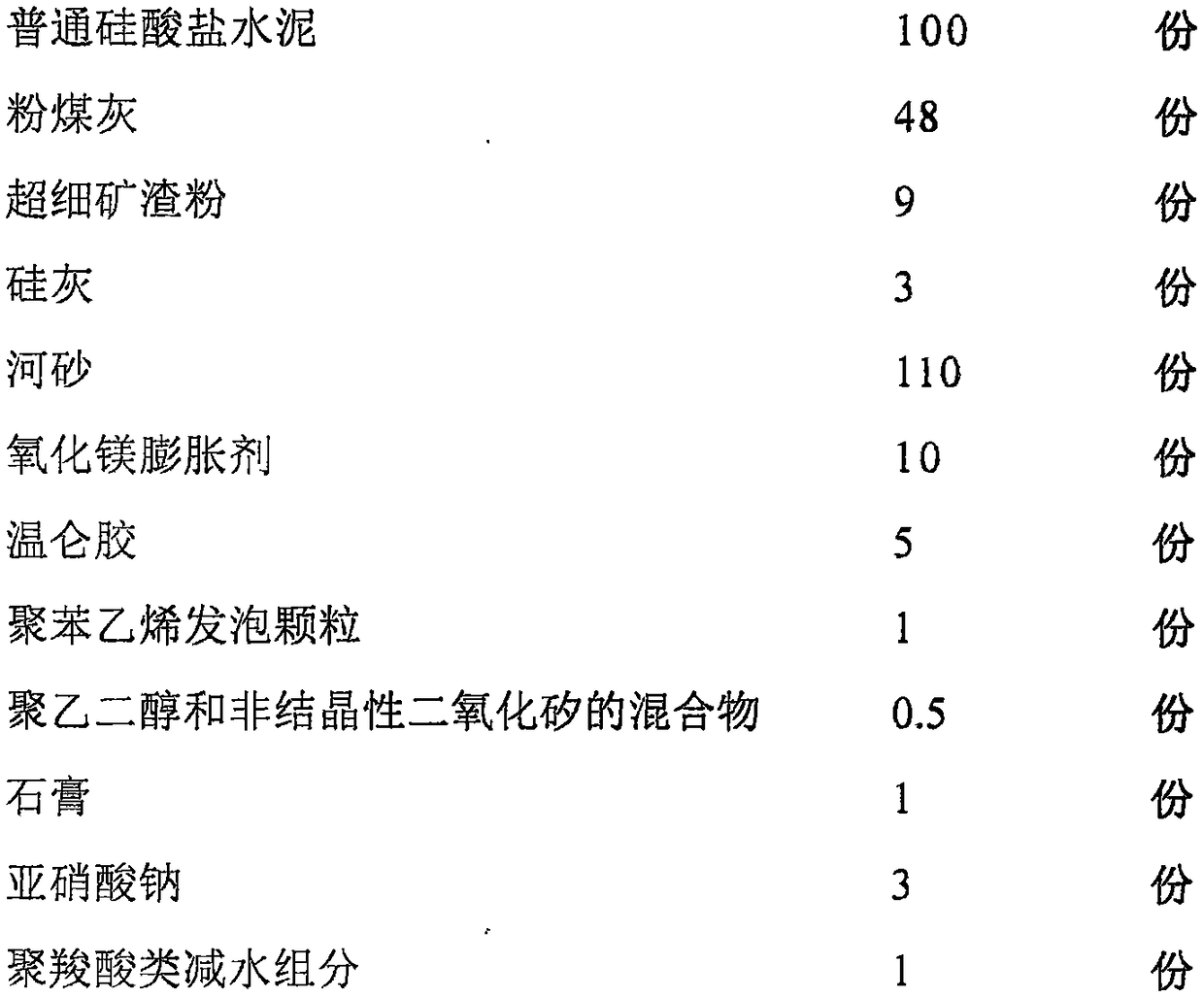

[0031] Restoration materials are counted as:

[0032]

[0033] How to use: Add 100 parts of repair materials, 90 parts of 5-10mm, 10-20mm continuous graded coarse aggregate and 17 parts of water in a forced concrete mixer according to the ratio and mix them evenly.

[0034] The main properties are shown in Table 1 below.

Embodiment 3

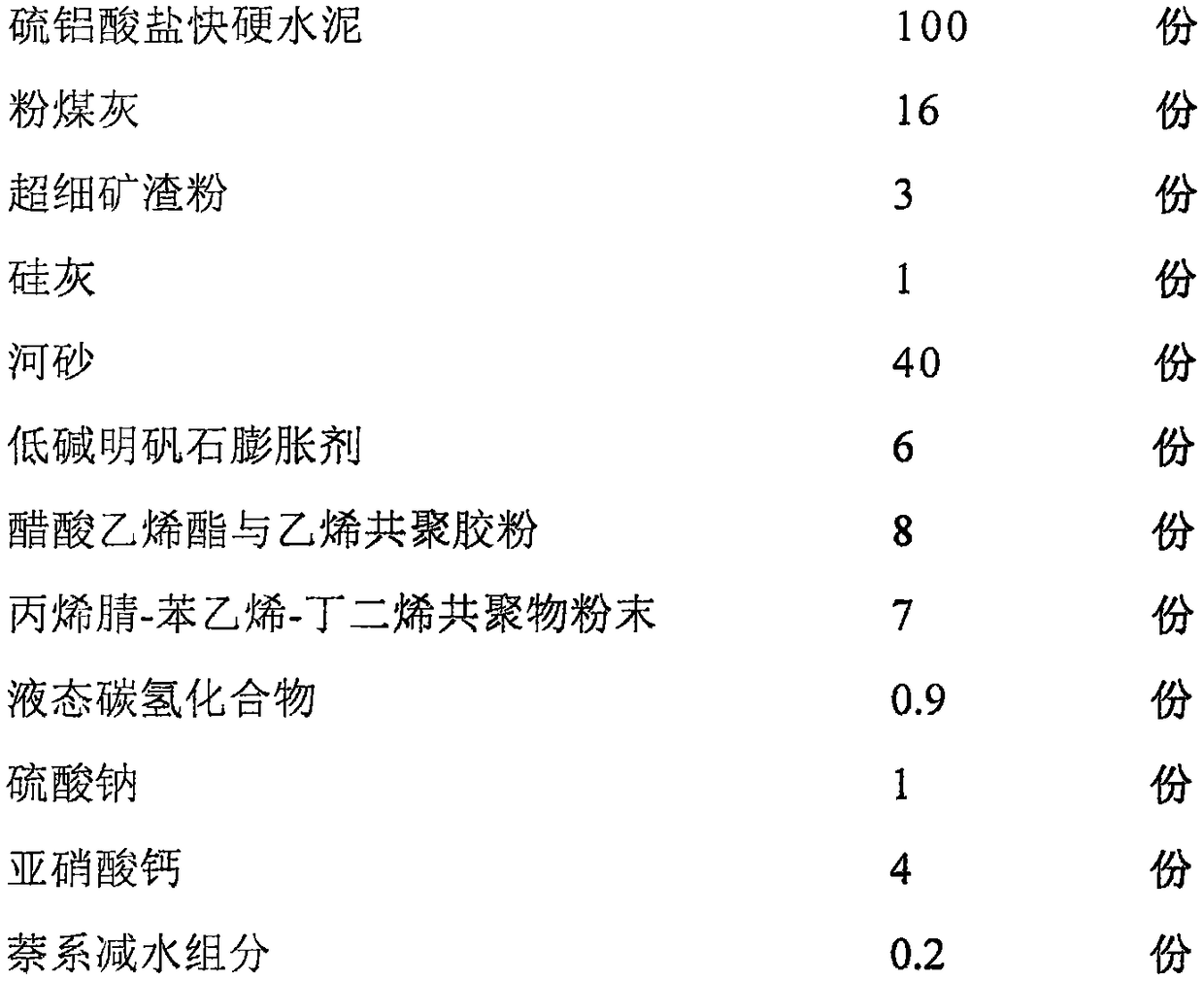

[0036] Restoration materials are counted as:

[0037]

[0038] How to use: Add 100 parts of restoration materials, 80 parts of 5-10mm, 10-20mm continuous graded coarse aggregate and 14 parts of water successively, and mix them evenly with a concrete mixer.

[0039] The main properties are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com