Coating method of corrugated pipe assembly for high-voltage switch

A technology of bellows assembly and high-voltage switch, which is applied to devices for coating liquid on surfaces, coatings, pre-treatment surfaces, etc., can solve the problems of reduced coating bonding force in local areas, coating damage, and economic losses of enterprises, etc. Achieve the effect of ensuring safe service and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

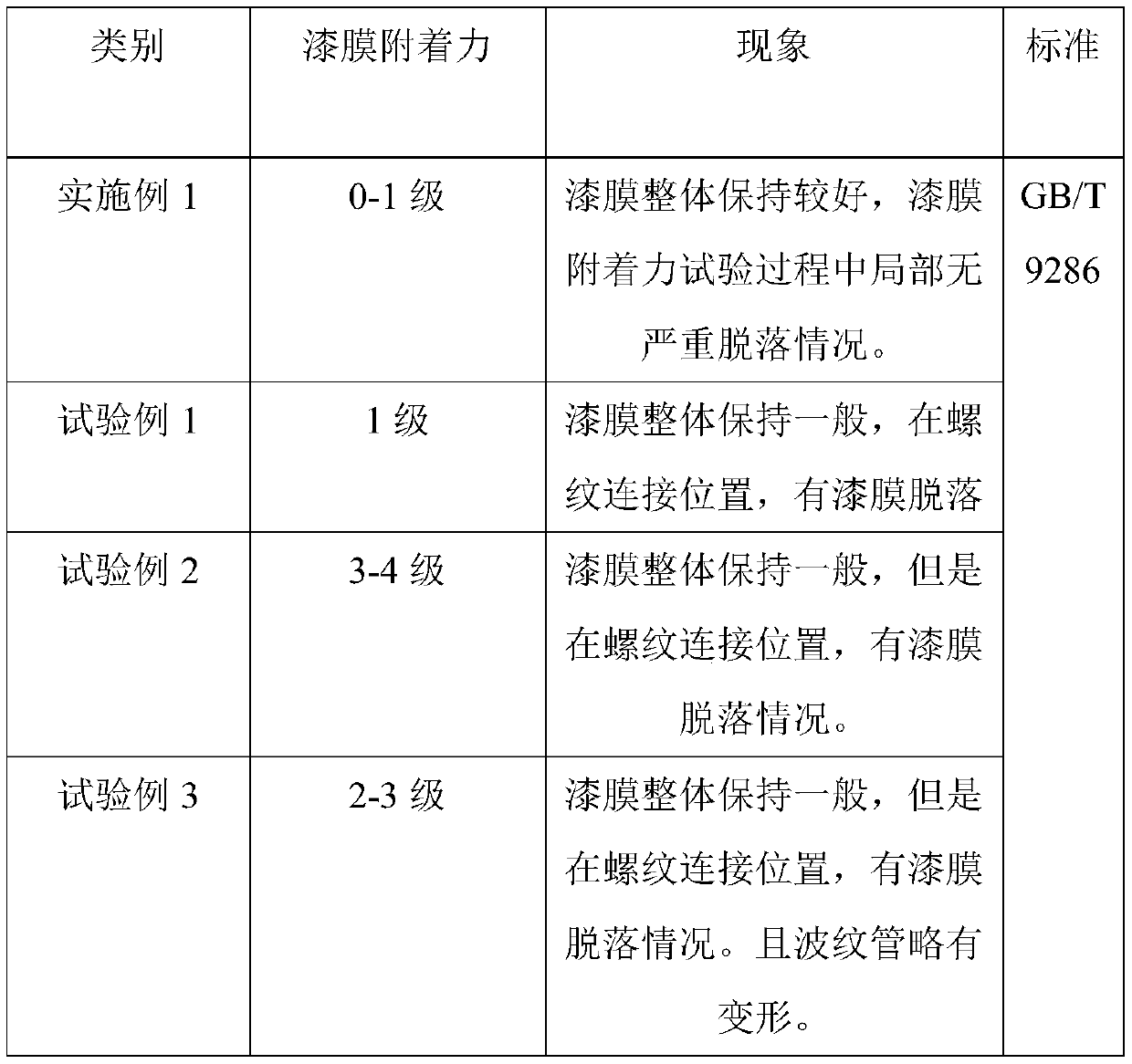

Embodiment 1

[0027] The coating method of the bellows assembly of the present embodiment comprises the following steps:

[0028] 1) Grind the bellows assembly as a whole, using 80# sandpaper for grinding; then clean it with 93# gasoline until no scale and oil stains appear on the surface of the bellows assembly; then put the cleaned bellows assembly into the drying furnace , heated to 50°C and baked for 15 minutes.

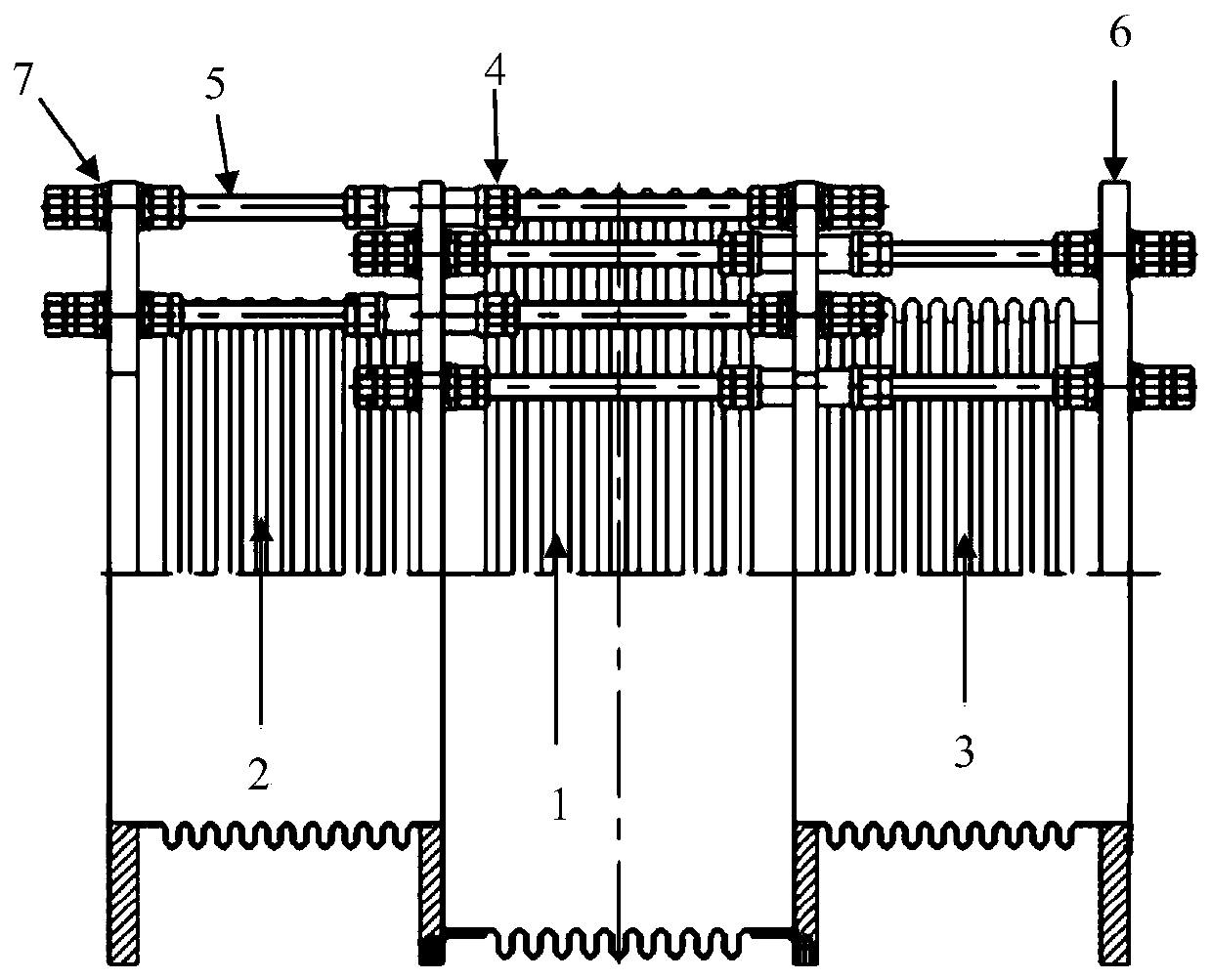

[0029] 2) Use 80# sandpaper to polish around the connection between the bellows component hole 7 and the flange 6, and then use 93# gasoline to clean it until no dirt particles appear near the hole 7 bonded with tape (tape brand Happy Unified brand); then put the cleaned bellows assembly into a drying oven, heat it to 50°C and keep it warm for 15 minutes.

[0030] 3) Spray the primer twice continuously on the surface of the bellows assembly, and the spraying pressure is 0.3Mpa.

[0031] 4) Baking the corrugated pipe assembly sprayed with the primer at 80° C. for 30 minutes t...

Embodiment 2

[0035] The coating method of the bellows assembly of the present embodiment comprises the following steps:

[0036] 1) Grind the bellows assembly as a whole, using 100# sandpaper for grinding; then clean it with 93# gasoline until no scale and oil stains appear on the surface; then put the cleaned bellows assembly into a drying furnace and heat it Bake at 55°C and keep warm for 12 minutes.

[0037] 2) Use 100# sandpaper to polish around the connection between the bellows component hole 7 and the flange 6, and then clean it with 93# gasoline until no dirt particles appear near the hole 7 bonded with tape (tape brand for Happy Unification brand); then put the cleaned bellows assembly into a drying oven, heat it to 55°C and keep it warm for 12 minutes.

[0038] 3) Spray the primer twice continuously on the surface of the bellows assembly, and the spraying pressure is 0.4MPa.

[0039] 4) Baking the corrugated pipe assembly after spraying the primer at 100° C. for 40 minutes to d...

Embodiment 3

[0043] The coating method of the bellows assembly of the present embodiment comprises the following steps:

[0044] 1) Grind the bellows assembly as a whole, using 80# sandpaper for grinding; then clean it with 93# gasoline until no scale and oil stains appear on the surface; then put the cleaned bellows assembly into a drying furnace and heat Bake at 45°C and keep warm for 15 minutes.

[0045] 2) Use 100# sandpaper to polish around the connection between the bellows component hole 7 and the flange 6, and then clean it with 93# gasoline until no dirt particles appear near the hole 7 bonded with tape (tape brand for the Happy Unification brand); then put the cleaned bellows assembly into a drying oven, heat it to 45°C and keep it warm for 15 minutes.

[0046] 3) Spray the primer twice continuously on the surface of the bellows assembly, and the spraying pressure is 0.4MPa.

[0047] 4) Baking the corrugated pipe assembly after spraying the primer at 100° C. for 40 minutes to d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com