Monitoring sensor for accumulated fatigue damage of mechanical structure under normal load distribution rule, design method and monitoring method

A technology for monitoring sensors and normal distribution, which is applied in the testing of machines/structural components, testing of mechanical components, instruments, etc., and can solve problems such as normal operation and inability to accumulate fatigue analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

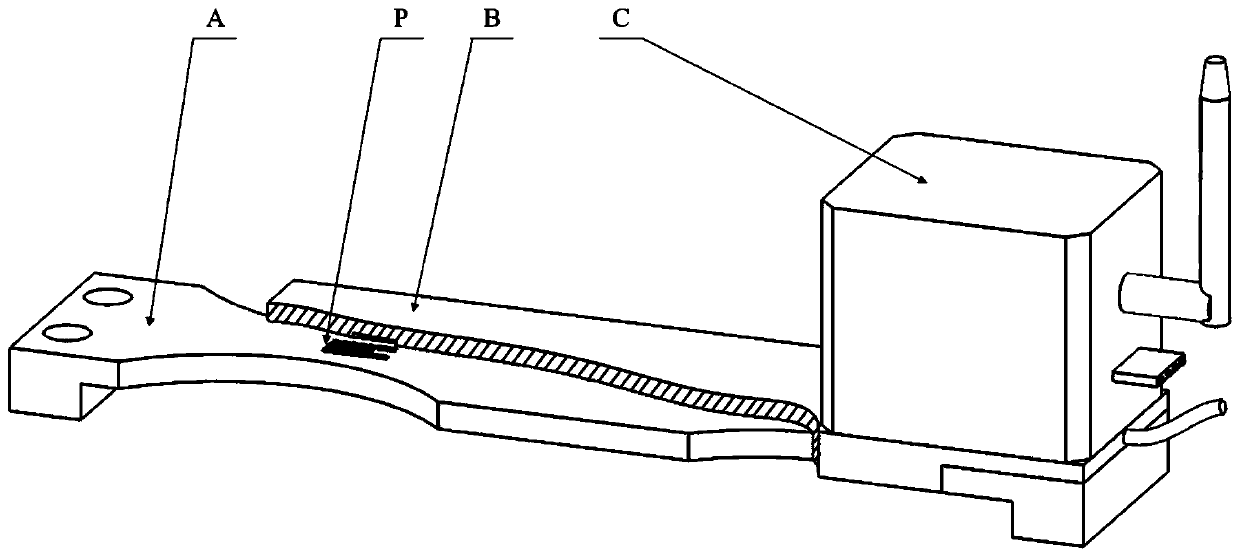

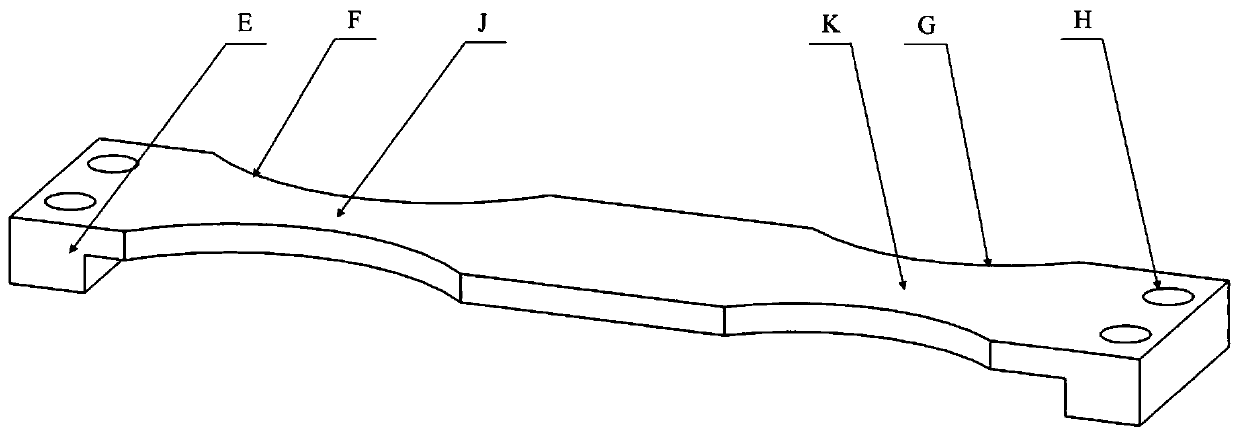

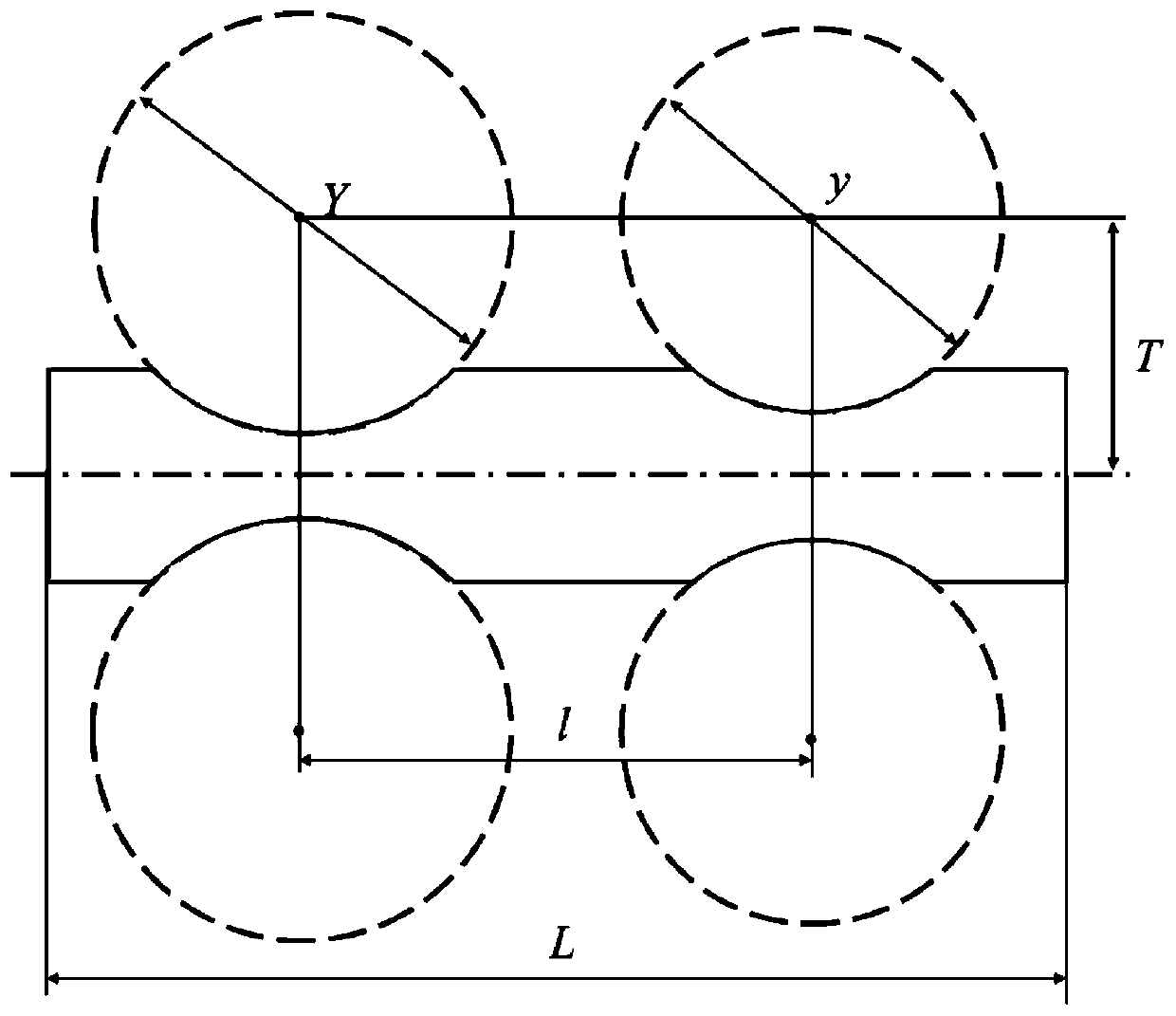

[0071] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

[0072] Figure 5 Schematic diagram of the specific work of the sensor for fatigue damage monitoring.

[0073] Installation Fatigue damage monitoring sensor S is installed on the surface of the mechanical part M under test. The mounting foot E of the sensor S bears the surface stress of the mechanical structure and transmits the stress to the stretching arm A. The strain amplification bridge of the stretching arm A passes through the stress concentration. The principle realizes the real-time amplification of the strain. The wireless node C is connected to the fatigue life foil through the wire of the flexible packaging structure B, and its resistance accumulation is obtained in real time, so as to realize the monitoring of the surface strain of the enlarged structure; according to the monitored data, throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com