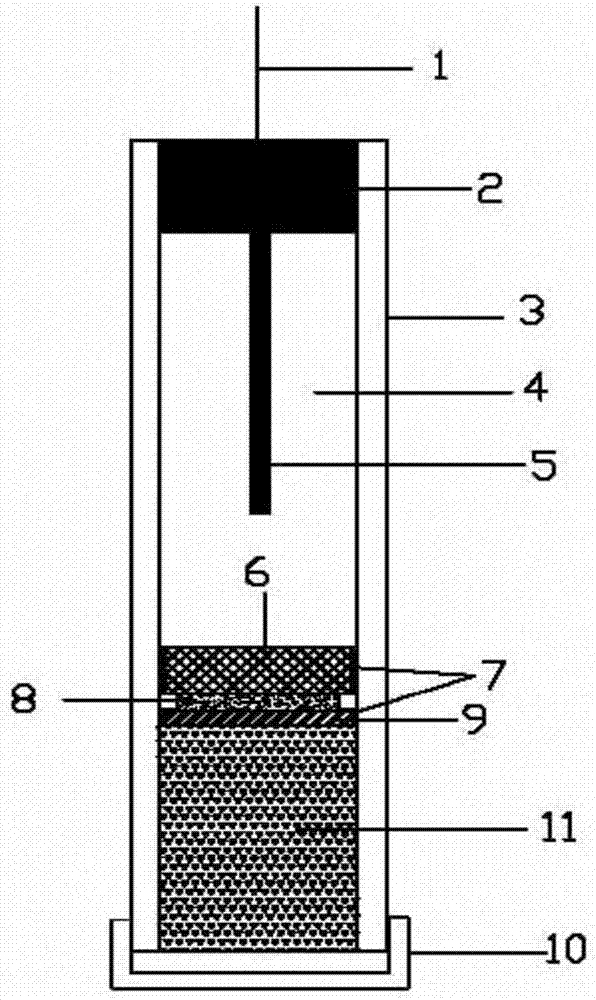

Pre-embedded reference electrode for monitoring corrosion of reinforced concrete, and manufacturing method

A reinforced concrete and corrosion monitoring technology, which is applied in the field of corrosion and protection of reinforced concrete structures, can solve the problems of restricting the corrosion monitoring of steel bars and the inability to meet the full life cycle monitoring of the corrosion state of steel bars, and achieve a good transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0024] The embodiment of the present invention is aimed at the specific implementation of the reference electrode after adding the post-activation seal and the water-absorbing swelling material. It is an embodiment to use the Ag / AgCl electrode as the electrode body to form the reference electrode of the present invention, but it is necessary to distinguish the actual There are Ag / AgCl reference electrodes and reference electrodes formed by the present invention using Ag / AgCl electrodes. As mentioned above, the preparation of the Ag / AgCl electrode body is not an example alone, and the same is tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com