Distorted concrete construction equipment

A technology of metamorphic concrete and construction equipment, applied in the direction of infrastructure engineering, construction, etc., which can solve the problems of difficult control of the filling position and range of filling grout, heavy maintenance and repair tasks, blockage of grouting pipelines, etc. To achieve the effect of simplifying the construction process, improving construction efficiency and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment the present invention is further described.

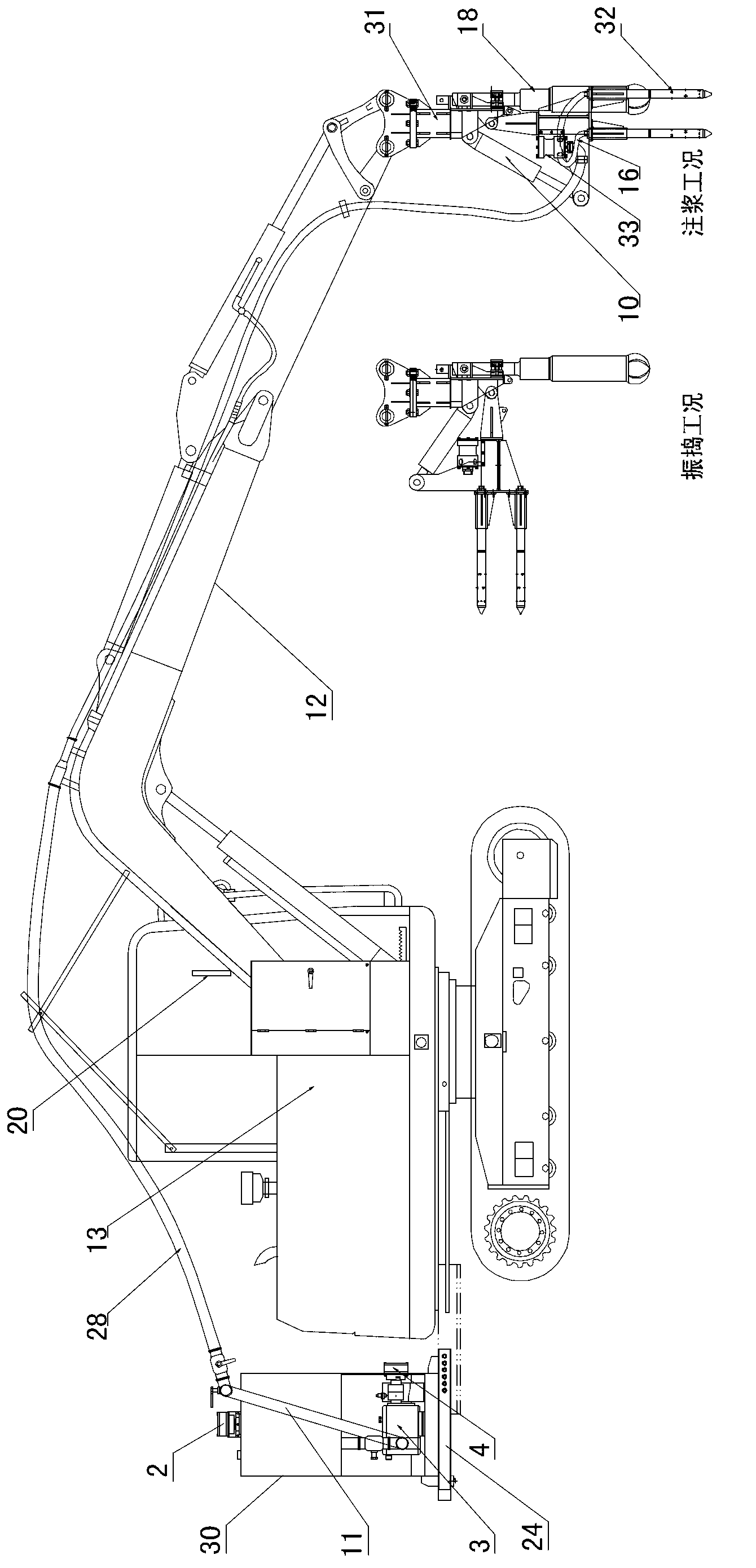

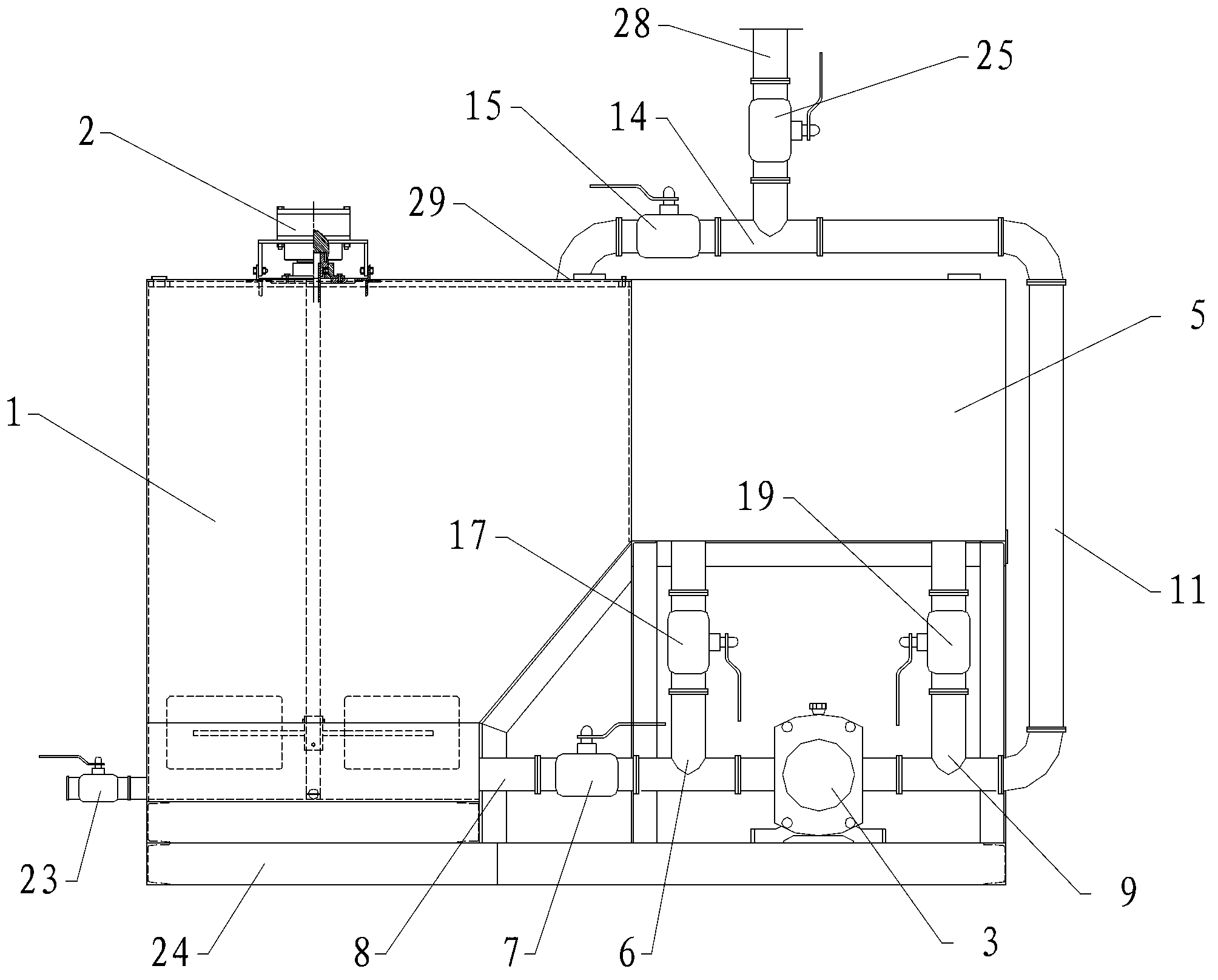

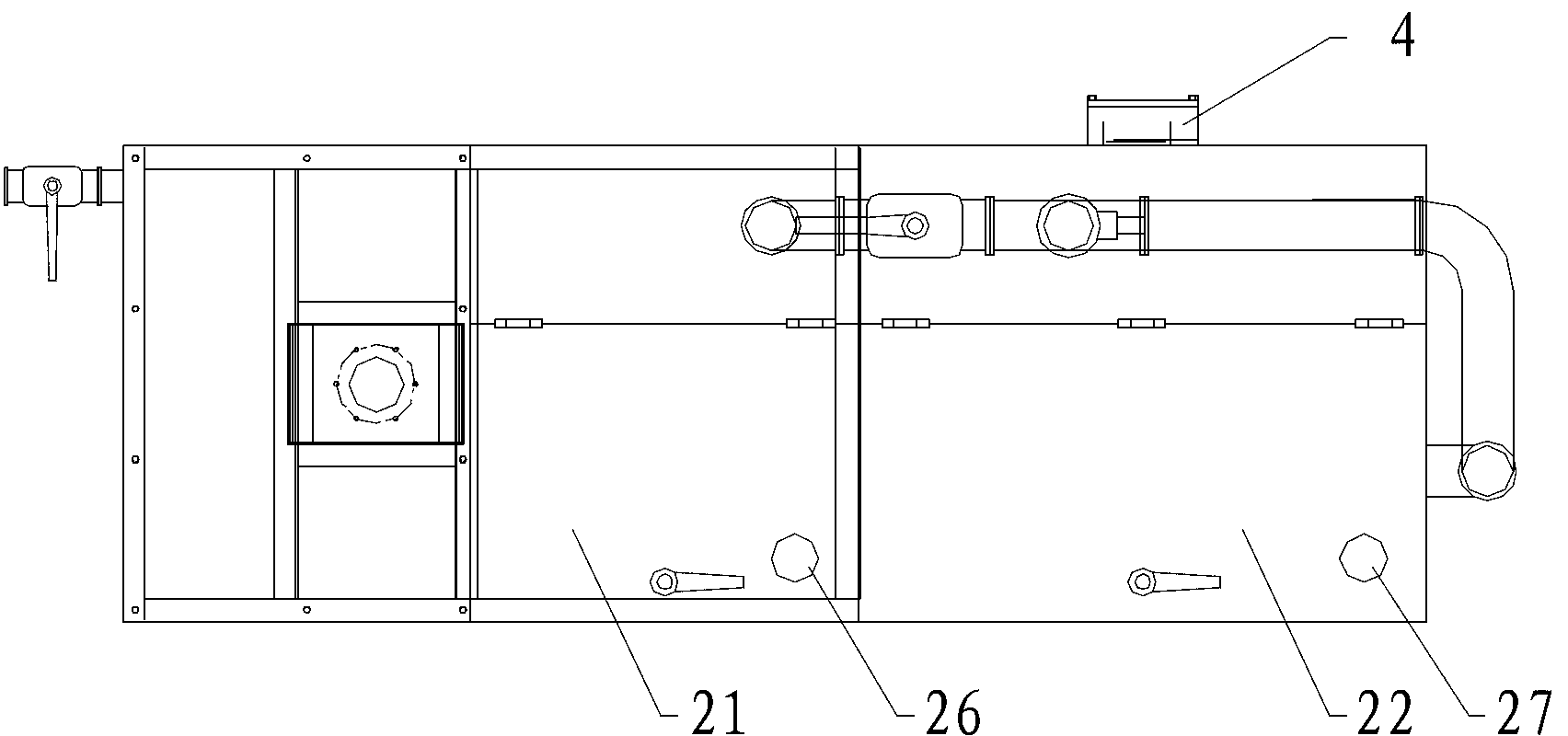

[0021] see figure 1 —3, metamorphic concrete construction equipment, including host 13, PLC system 20, action arm (2, vibrator 18, grouting device 32, turning oil cylinder 10 and mortar pumping device 30, action arm 12 is connected to vibrator via connector 31 The tamping rod 18 is connected, and the mortar pumping device 30 is connected with the grouting device 32 through the grouting pipe 28; the mortar pumping device 30 includes a frame 24, a slurry tank 1, a mixer 2, a rotor pump 3 and a motor 4, and also includes a cleaning water tank 5. The slurry outlet pipe 8 at the lower part of the slurry tank 1 is connected to the rotor pump 3 through the slurry outlet valve 7 and the slurry outlet tee 6; The slurry valve 15 is connected to the slurry return hole 29 of the slurry tank 1; the branches of the slurry outlet tee 6 and the pump tee 9 are connected to the bottom of the cleaning wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com