Multi-section type hollow grouting cable anchor and supporting method

A grouting anchor cable, multi-stage technology, applied in tunnels, geotechnical engineering, underground engineering anchor cable support, mining fields, can solve the problem of multi-level segmented grouting reinforcement, uneven diffusion of grout in boreholes, The problem of low grouting amount in deep rock cracks can achieve the effect of improving the grouting effect, increasing the amount of grouting, and improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

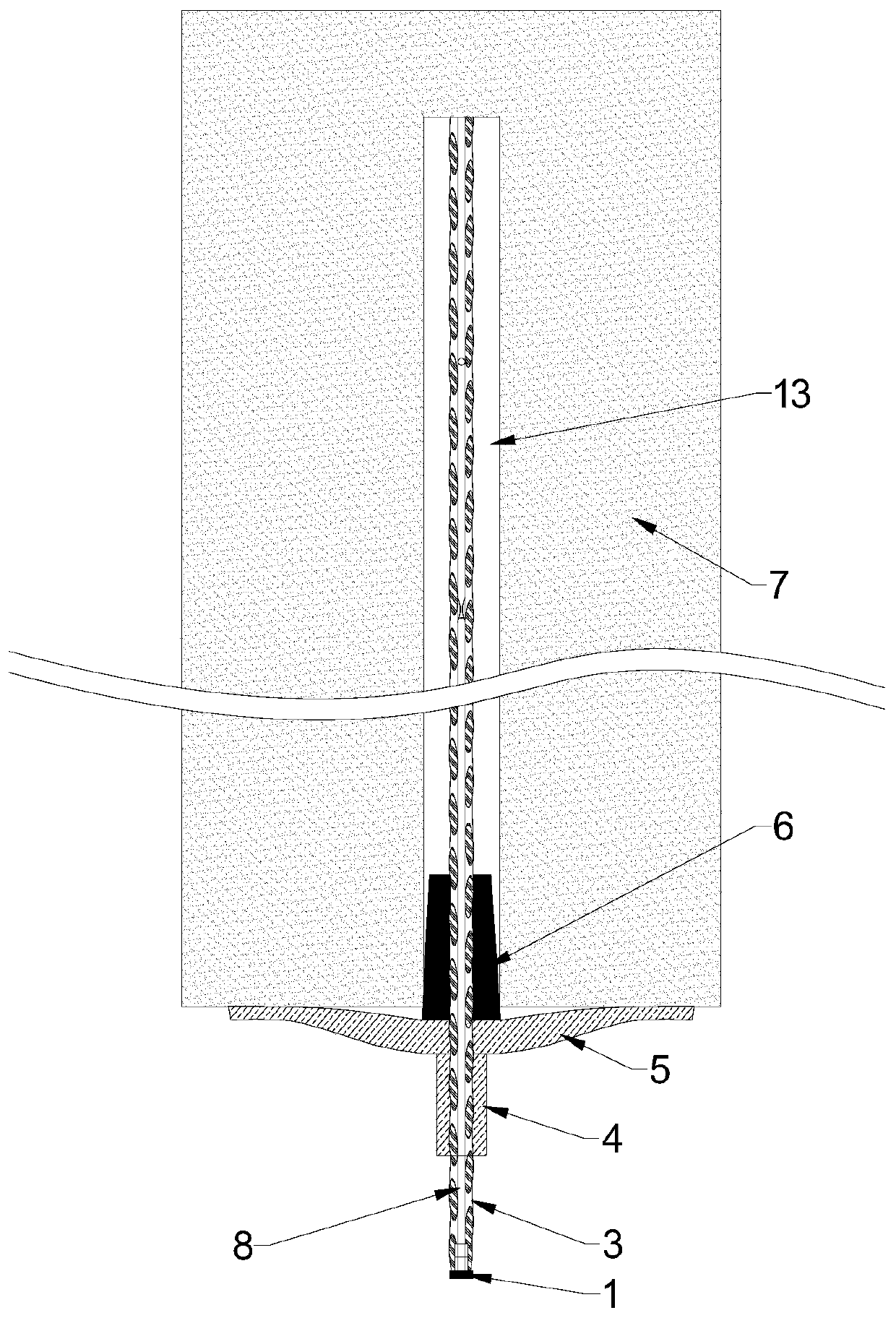

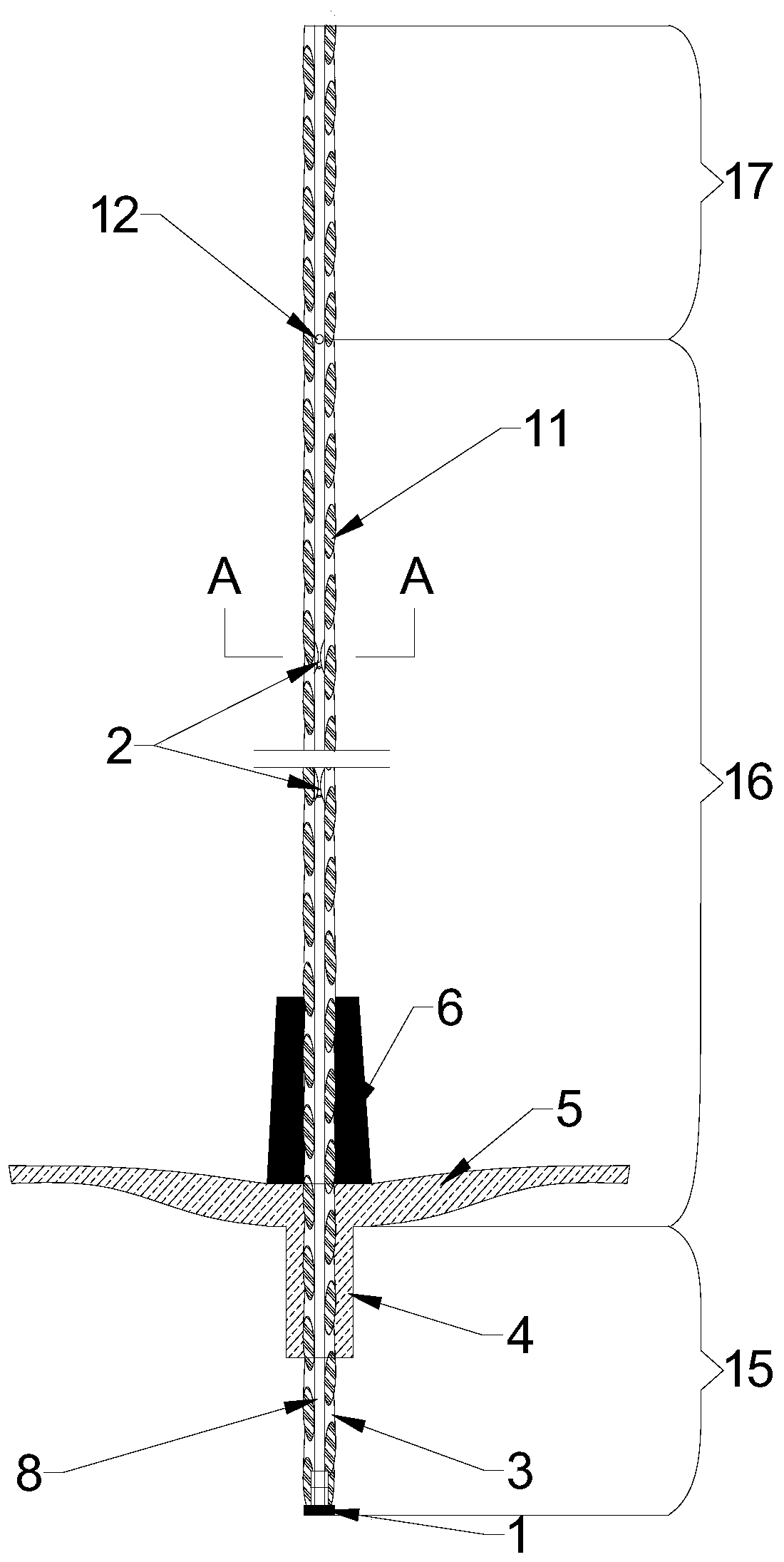

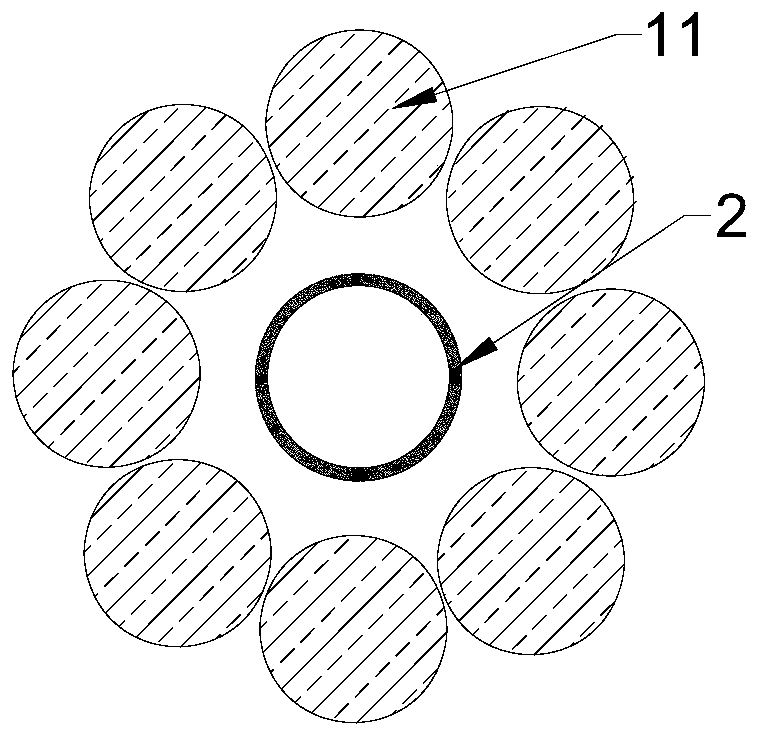

[0038] A specific embodiment of the present invention discloses a multi-section hollow grouting anchor cable, such as to 1 image 3 As shown, the cable body 3 is included, the cable body 3 is composed of a plurality of steel strands 11 spirally wound around the grouting pipe 8, the spirally wound steel strands 11 wrap the grouting pipe 8, and the pitch of the wound steel strands 11 is greater than The diameter of the steel strand 11; the grouting pipe 8 is provided with a plurality of flow-limiting components, and the multiple flow-limiting components divide the grouting pipe 8 into a plurality of segmented pipelines; wherein, the flow-limiting components can divide two adjacent segments The pipelines are separated and can be opened under the threshold pressure of the flow-restricting assembly to connect the adjacent two segment pipelines. Open under a certain hydraulic pressure to connect the adjacent two segmented pipelines; a slurry outlet 10 is set on the flow limiting com...

Embodiment 2

[0047] The multi-section hollow grouting anchor cable of this embodiment uses the grouting anchor cable sealing assembly 1 to replace the plug in the first embodiment to seal the grouting port of the grouting pipe 8, as Figure 5 to Figure 6 As shown, the grouting anchor cable sealing assembly 1 includes a housing 1-8, a spring 1-3 and a grout stop piston 1-4, and the housing 1-8 is provided with a piston chamber for installing the grout stop piston 1-4. The grout stop piston 1-4 is located in the piston cavity and can move in the piston cavity; one end of the grout stop piston 1-4 is fixedly connected with the bottom wall of the piston cavity by a spring 1-3, and the other end of the grout stop piston 1-4 One end is a free end, and the free end can be in contact with the slurry entering the piston cavity, that is to say, the tail end of the slurry stopper 1-4 is connected to the spring 1-3, and the head end of the slurry stopper 1-4 can be connected to the piston cavity. In c...

Embodiment 3

[0059] This embodiment provides a support method, using the multi-section hollow grouting anchor cables in Embodiment 1 and Embodiment 2 for support, including the following steps:

[0060] The first step: Determine the grouting parameters and make preliminary preparations. According to the geological general situation and production conditions, the grouting parameters of the grouting anchor cable are determined, wherein the grouting parameters include the number of segmented pipelines of the grouting pipe 8, the pipe diameter, the diameter and the quantity of the steel strand, and the diameter and quantity of the anchor cable hole 13. Hole diameter and depth, grouting pressure, etc. Determine the number of grouting sections according to the actual conditions, wherein the grouting pipe 8 is n sections, and the expansion pipe 2 is n-1 sections; the grouting pump is arranged in the designed roadway, and the anchor cable hole 13 is pre-drilled in the roadway coal rock mass 7 acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com