Block assembly type yielding hollow grouting anchor rod and construction method thereof

A technology of segmented assembly and grouting bolts, which is used in the installation of bolts, earth-moving drilling, mining equipment, etc. Long anchorage and other problems, to achieve the effect of preventing tensile failure, improving integrity and deformation coordination, and high initial preload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

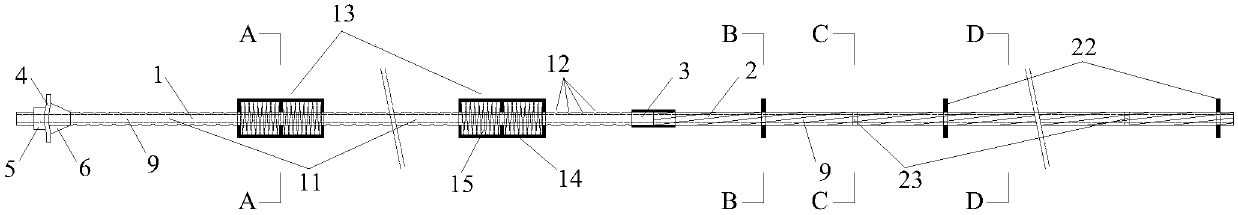

[0036] like figure 1 As shown, a segmented assembly pressure yielding hollow grouting anchor includes a hollow anchor body 1, a hollow anchor cable body 2, a pressure yielding device 13 arranged on the hollow anchor body 1, a tray 4, a nut 5 and The grout stopper 6, the anchor cable hoop 22 and the reaming device 23 arranged on the hollow anchor cable rod body 2, the hollow anchor rod body 1 and the hollow anchor cable rod body 2 are connected through the connecting sleeve 3.

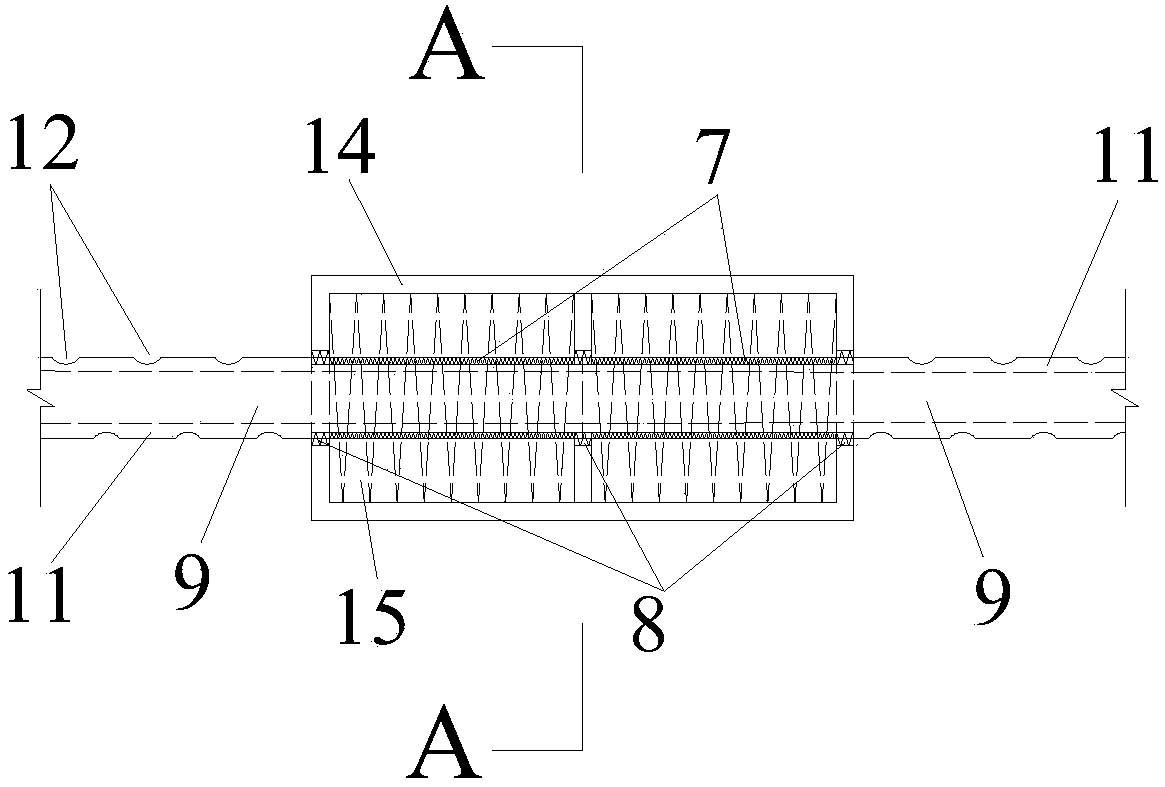

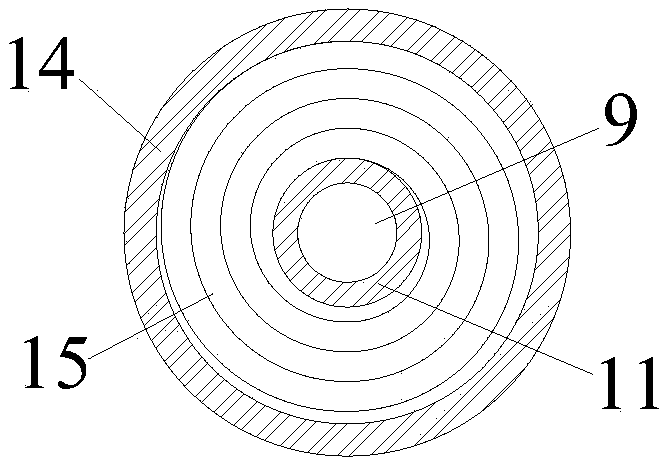

[0037] like figure 2 As shown, the hollow anchor body 1 includes a multi-section segmented hollow anchor body 11, the length of the segmented hollow anchor body 11 is 1.0 m, and the number is 4, and the two ends of the segmented hollow anchor body 11 are externally threaded 7 processing, the length of the external thread 7 is half of the length of the pressure relief device 13, that is, 0.2m, and the holes of Φ5mm are pierced every 50mm in the radial direction as the anchor grouting hole 12, and the p...

Embodiment 2

[0048] A segmented assembly type yielding pressure hollow grouting anchor, wherein the length of the segmented hollow anchor body 11 is 1.0m, the number is 2, the length of the yielding device is 0.4m, the number is 1, and the hollow The anchor rod body 2 is formed by 8 steel strands 21 reversely twisted and closely fitted, and the length is 6300mm. All the other construction methods and steps are the same as in Example 1.

Embodiment 3

[0050] A segmented assembly type yielding pressure hollow grouting anchor, in which the length of the segmented hollow anchor body 11 is 0.5m, and the number is 6, the length of the yielding device is 0.4m, the number is 5, and the hollow The anchor rod body 2 is formed by 14 steel strands 21 reversely twisted and closely fitted, and the length is 5000 mm. All the other construction methods and steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com